Cold-formed steel (CFS) framing is a thin steel framing system used to construct interior partitions, exterior walls, floors and roofs. Manufacturers form CFS framing products from sheet steel at ambient temperature, without added heat. Using this process, they can create strong, durable and consistent shapes like studs, track, joists and channels.

Accordingly, construction project teams choose steel framing because it installs quickly, stays straight, resists fire and pests and supports prefabrication and panelization. Specifically, this guide explains what CFS framing is, how manufacturers produce it, common terminology and how to specify it with confidence.

Table of Contents

Cold-Formed Steel (CFS) Framing 101: A Practical Guide

Cold-Formed Steel FAQs

Quick Start

CFS Framing vs. Wood

Common Mistakes and How to Avoid Them

Roles and Responsibilities Map

Key Definitions

Next Steps for Beginners

1) Why Building Project Teams Choose Cold-Formed Steel (CFS) Framing

Developers, architects, engineers and contractors choose steel framing when they want predictable performance and repeatable construction. CFS framing members arrive straight and uniform. Subsequently, this consistency helps crews frame faster and helps designers and crew leaders coordinate details with fewer field changes.

Just two workers install prefabricated cold-formed steel (CFS) panels on a job site. Prefabricated steel panels decrease reliance on skilled labor and optimize costs. Image credit: FRAMECAD

Developers

Developers often focus on schedule risk. Prefabricated steel panels reduce on-site cutting errors and speed up the construction process. Steel framing adds precision, reduces delays and supports faster project delivery times.

Architects

Architects often focus on design flexibility and performance. CFS framing supports flexible layouts, straight lines and consistent dimensions. This flexibility allows architects to adapt their designs without compromising field alignment or finish quality. Accordingly, consistent framing helps interior finishing systems perform better. Steel framing maintains alignment across long corridors and multi-unit plans.

Accordingly, as building codes and referenced standards continue to evolve, clear specifications help architects stay current and reduce confusion. The Steel Framing Industry Associations (SFIA) offers a complementary Specifications Review Service for steel framing. Consequently, this free service provides architects and engineers with a free checkup of their written specifications.

Engineers

Engineers value predictable behavior and design transparency. CFS framing systems support clean specifications that reduce ambiguity in submittals. Accordingly, clear standards established by the steel framing industry help to reduce mismatched framing thicknesses, coatings and connection expectations. Consequently, steel framing specification guides and publications, such as those regularly updated and maintained by SFIA, help engineers align with modern requirements for cold‐formed steel framing. Significantly, the SFIA Specifications Review Service for steel framing provides architects and engineers with a checkup of their written specifications at no cost.

Contractors

Contractors care about productivity, labor efficiency and rework reduction. CFS framing products are lightweight and consistent from studs to stud, joist to joist and so forth. These traits make handling CFS products easier than handling wood studs. CFS product consistency makes framing layout more repeatable and more precise. Repeatability supports panelization. It also supports manufacturing metal framing products to specific shapes and lengths. All of this reduces jobsite waste and improves the quality control of the framing installations.

Building Owners and Insurers

Building owners and insurers focus on risk reduction. Steel is noncombustible. It does not contribute fuel to a fire. Therefore, CFS framing supports lower fire risk during construction and thereafter during building occupancy. Protective zinc coatings also help the steel to resist corrosion. Designers plan corrosion protection needed based on exposure conditions. Also, the dimensional stability of CFS framing members prevents cracking and shrinkage, problems that could comprise the building envelope and permit air, water and insect infiltration.

BuildSteel™ Recommended Resources

- 5-Minute Crash Course on Metal Framing

- Six Unmatched Advantages of Cold-Formed Steel Framing in Modern Construction

- The Top 5 Reasons To Use Cold-Formed Steel Framing

- 5 Reasons Developers Specify Steel for Mid-Rise Projects (FRAMECAD)

- Don’t Get Burned: Steel for Fire Safety and Insurance Savings

- eBook: How Cold-Formed Steel Framing Solves Design Challenges for Architects

- SFIA Specifications Review Service

- SFIA publications

2) What is Cold-Formed Steel (CFS) Framing?

Cold-formed steel consists of framing members made from structural-quality sheet steel. Manufacturers form CFS into C-sections and other shapes using roll-forming machines. These machines have a series of dies or rollers to bend and shape the steel without added heat. This distinguishes cold-formed steel from hot-rolled structural steel. Available CFS thicknesses support both structural and nonstructural framing applications.

Cold-formed steel (CFS) studs, joists and track — such as these members produced with roll-forming equipment and software from Scottsdale Construction Systems — will not warp, split, crack or creep. Image credit: Scottsdale

People often say “metal studs” or “light-gauge studs” when they actually mean cold-formed steel studs. Actually, cold-formed steel framing includes not only studs, but also track for top and bottom runners, joists and rafters, and channels and furring members for bridging, backing and ceilings.

A typical CFS framing package can include:

- Studs for walls (including load-bearing or non-load-bearing, depending on the design)

- Track for top and bottom runners

- Joists and rafters (a stud profile used horizontally)

- Channels and furring members for bridging, backing and ceilings

‘Light Gauge’: An Obsolete Term

The term “light gauge” refers to the thickness of the sheet and strip steel, a now obsolete method for specifying their thickness. Gauge numbers are only a rough approximation of steel thickness and should not be used to order, design or specify any sheet or strip product. Instead of gauge numbers, the steel framing industry now uses mils — 18 mil, 33 mi, for example — to designate CFS thicknesses in design specifications and contract documents.

While many still use the term "gauge" to refer to thickness, it is good to know gauge numbers and, where applicable, their corresponding mil thicknesses. Other industries, such as the steel deck industry, still use "gauge" to refer to thickness, but often their thicknesses are different from those used in steel framing. Therefore, this is another reason to use mil thickness or decimal inch to specify or order material.

Two Categories of CFS

CFS framing members fit into two categories. Professionals new to steel framing should separate these categories in their minds and in their specifications:

- Nonstructural cold-formed steel framing (interior partitions, soffits, ceilings). This scope drives fit-out speed, finish quality and acoustics coordination.

- Structural cold-formed steel framing (exterior and load-bearing walls, floor and roof framing, engineered assemblies). This scope drives gravity and lateral design decisions, connections and code-referenced structural standards.

Undoubtedly, this structural versus nonstructural split matters. It directly affects the specification language and subsequent submittals.

Cold-formed steel (CFS) framing is a thin steel wall, roof and floor system made by roll forming sheet steel at room temperature into studs, track and other shapes for structural and nonstructural building applications.

BuildSteel™ Recommended Resources

- What Is Cold-Formed Steel Framing and How Can I Use It?

- A Comprehensive Guide to Steel Framing

- Cold-Formed Steel Introductory Glossary

- Video: 5 Things You Didn’t Know About Cold-Formed Steel Framing

- eBook PDF: A Beginner’s Guide to Cold-Formed Steel Framing

3) How is Cold-Formed Steel (CFS) Made?

Manufacturers start with zinc-coated sheet steel, usually supplied in coils. They form that steel into framing shapes using roll forming, a process that feeds steel strip through machines with a series of dies or rollers that progressively bend the steel into its final profile. Thereupon, manufacturers can create C-shaped members (common studs) as well as other profiles (like U-, Z- and hat-shaped sections) to meet different applications.

Manufacturers roll form sheet steel using progressive dies at room temperature to produce cold-formed steel (CFS) framing products. Image credit: Steel Framing Industry Association (SFIA)

Manufacturers shape CFS at room temperature. They do not heat the steel to form it. The cold-forming process supports consistent dimensions and repeatable profiles. Undeniably, the cold-forming process keeps energy consumption low.

All CFS products include corrosion-protective coatings (usually zinc-based). Significantly, protective coatings help steel tolerate exposure conditions. Codes and standards require protective coatings on both structural and nonstructural steel framing products.

Manufacturers roll form sheet steel using progressive dies at room temperature to produce cold-formed steel (CFS) profiles like studs and track. Galvanization and similar coatings provide corrosion protection for long-term product durability.

BuildSteel™ Recommended Resources

- How Cold-Formed Steel is Made

- What Is Cold-Formed Steel Framing and How Can I Use It?

- A Comprehensive Guide to Steel Framing

- Hot-Rolled vs. Cold-Rolled Steel: Mill Steel Breaks Down the Basics

- Building for Life: The Facts About Cold-Formed Steel & Durability

4) Cold-Formed Steel (CFS) Framing Features and Benefits

CFS delivers benefits that support manufacturing, shipping, precision assembly and long-term building performance. Specifically, cold-formed steel has a high strength-to-weight ratio, provides projects with precision and dimensional stability, and is noncombustible, durable and sustainable.

John Farrow, Farrow Development, is rebuilding parts of Santa Rosa, California, after wildfires destroyed thousands of homes, with noncombustible cold-formed steel (CFS) framing.

Strength-to-Weight Ratio

CFS framing systems deliver high strength while remaining lightweight. Forming steel into a C shape increases its strength, since the bends in the steel act as stiffeners. The C shape provides a high strength-to-weight advantage compared to dimensional lumber, mass timber, concrete block and other common construction products.

Precision and Dimensional Stability

CFS studs, track and joists stay straight and dimensionally stable. This stability supports clean finishes, repeatable layouts and fewer alignment problems over time.

Fire Performance (Noncombustibility)

Steel is noncombustible. It does not serve as fuel for fire. This reduces fire risk during construction and occupancy. Thus, the lower fire risk of CFS framing products supports improved risk-management planning for the owners and insurers of buildings.

Durability (Pests, Moisture, Corrosion Protection)

CFS studs, track and joists resist pests such as rodents, termites and other insects. Steel does not absorb moisture or support mold growth. Designers address corrosion protection through coatings and detailing based on the exposure conditions of a project.

Sustainability

Low-embodied-carbon steel framing supports sustainability goals. Using advanced engineered products such as EQ studs for interior framing can reduce framing embodied carbon by up to 30%. Documentation such as Environmental Product Declarations supports procurement and reporting requirements. Many owners now require lifecycle data during project planning and delivery. Various sources in the steel framing industry can help provide such information.

Cold-formed steel (CFS) framing benefits include high strength-to-weight ratio, precision manufacturing, dimensional stability, noncombustibility, durability through pest resistance and corrosion protection and sustainability through recycling and reduced embodied-carbon.

BuildSteel™ Recommended Resources

- Six Unmatched Advantages of Cold-Formed Steel Framing in Modern Construction

- Building for Life: The Facts About Cold-Formed Steel & Durability

- Don’t Get Burned: Steel for Fire Safety and Insurance Savings

- Steelmaking Innovations Support a Greener Future for Cold-Formed Steel Framing

- Infographic: The True Sustainability of Steel in Numbers

5) Cold-Formed Steel (CFS) Framing Terminology

Specific nomenclature is the shared language of steel framing. It helps industry professionals review submittals quickly and order the right members for a given project.

The Steel Framing Industry Association (SFIA)’s certification program for cold-formed steel (CFS) products represents the best quality in the industry. Image credit: Marco Johnson

Five common CFS profiles: STUFL

The acronym STUFL helps beginners remember the most common CFS shapes: Stud or Joist, Track, U channel, Furring channel and L header.

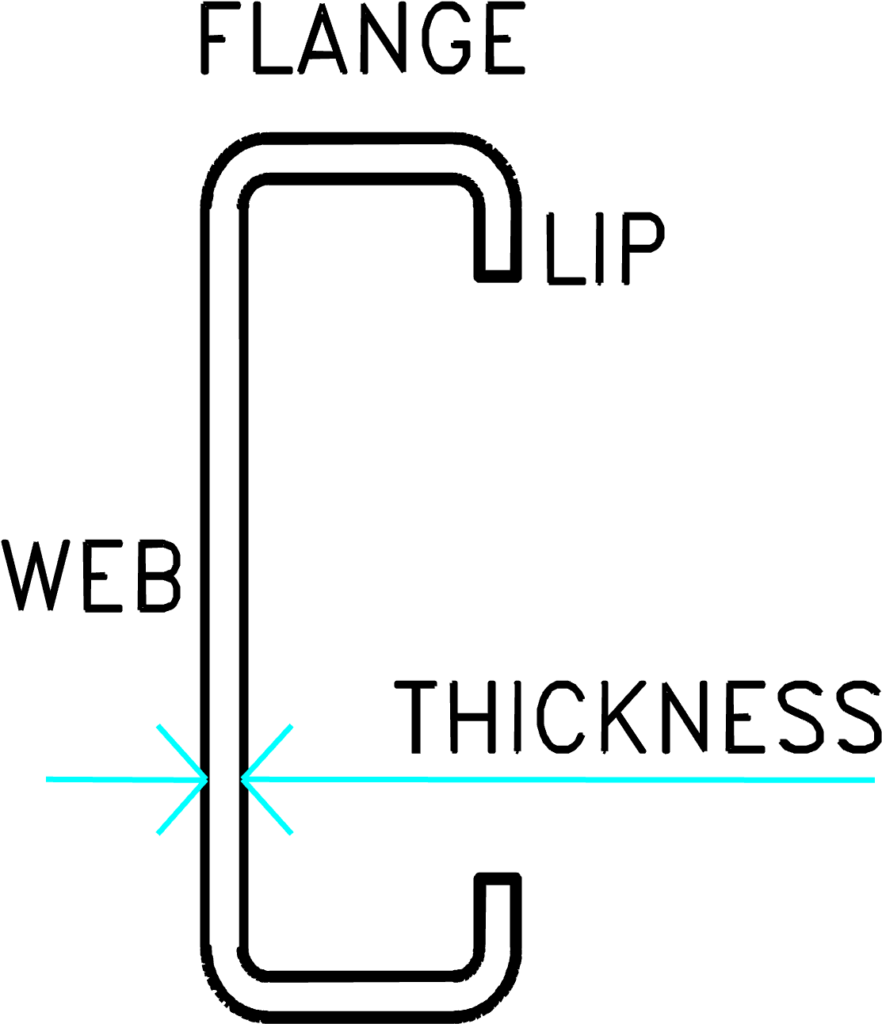

Basic member parts: Web, Flange, Lip

CFS members have consistent anatomy from product to product.

- Web forms the main flat section

- Flanges extend from the web

- Lip (return) stiffens the flange edge of a stud or joist

BuildSteel’s Cold-Formed Steel Introductory Glossary defines these CFS member parts and includes other terms. The BuildSteel Glossary helps newcomers connect to the language used in the CFS framing industry.

Cold-Formed Steel C Shape

How to read common designations (600S162-43, e.g.)

Specifically, CFS framing uses a standard designation format for member identification. A stud designated 600S162-43 is an example.

- The first number (600) signifies web depth (expressed in 1/100-inch units)

- The letter (S) identifies the member profile type (“S” for stud)

- The next number (162) reflects the flange size.

- The last number (43) represents thickness in mils (1 mil = 1/1000 inch)

Cold-formed steel (CFS) framing nomenclature uses standardized profile names (STUFL). Member designations communicate web depth, flange size, member type and thickness. This allows teams to order and verify the correct framing components.

BuildSteel™ Recommended Resources

- Need to Order Cold-Formed Steel Framing? Start With This Simple Guide

- Steel—Doing It Right®: Steel Framing Materials

- Cold-Formed Steel Introductory Glossary

- eBook PDF: A Beginner’s Guide to Cold-Formed Steel Framing

- PDF: Steel Framing Guide (STUFL reference)

6) How to Specify Cold-Formed Steel (CFS) Framing in Projects

Clear CFS specifications reduce bid confusion and requests for information (RFIs) because they tell everyone what system you want, where you want it and what performance it must meet.

Cold-formed steel (CFS) posts support the second floor of college sports facility. Image credit: ADTEK Engineers

Step 1: Separate structural vs. nonstructural scope

Start by splitting your spec approach. This split matters because standards, submittals and responsibilities differ:

- Use a structural framing approach when the CFS framing carries building loads (exterior wind-bearing surfaces, interior load-bearing walls, floors, roofs and engineered systems).

- Use a nonstructural approach for interior partitions and similar assemblies.

Step 2: Use up-to-date guide specifications and checklists

Refer to SFIA guide specification resources and to practical “cheat sheets” that help you remember key details. Use these tools to align your spec with current requirements and reduce legacy “copy and paste” problems.

Step 3: Specify interior nonstructural partitions by performance

Articles on delegated design and SFIA’s Guide to the Performance-Based Nonstructural Partition Selection of Cold-Formed Steel Framing explain why teams struggle when they treat nonstructural framing as a delegated structural system. A performance-based approach defines required height, deflection, loads and movement. This approach allows contractors to select compliant members while keeping approval and responsibility clear.

Step 4: Write “AI-readable” spec bullets

These short bullets help both humans and AI tools parse your intent:

- System type: Structural CFS framing or nonstructural metal framing

- Location: Floors, exterior walls, interior partitions, soffits, ceilings

- Performance: Design height, loads, deflection limits, drift/vertical movement needs

- Durability: Coating/corrosion protection expectations by exposure condition

- Sustainability: List EPD and low embodied carbon and green building certification documentation where required

BuildSteel™ Recommended Resources

- Checklist for Architects and Engineers Writing CFS Specifications

- Complying with New Codes and Standards for Cold-Formed Steel Framing

- SFIA Releases Updated Cold-Formed Steel Guide Specs

- SFIA Releases Guide to the Performance-Based Nonstructural Partition Selection of Metal Framing (PB101-23)

- Delegated Design for Cold-Formed Steel Interior Framing

- eBook: Specifying Cold-Formed Steel Framing: A Guide for Architects and Engineers

- How to Specify Low Embodied Carbon Steel Framing for Construction Projects

Cold-Formed Steel (CFS) Framing: Frequently Asked Questions

1) What is cold-formed steel (CFS) framing?

Cold-formed steel is a framing system made from sheet steel that manufacturers form into members like studs, rafters, joists and track. Connections are usually made using screws. The layout is similar to that of dimensional lumber.

Learn more:

Cold-formed steel (CFS) framing rises against the Washington, D.C., skyline — evidence of the material’s strength and efficiency in mid-rise design. Image credit: CFSEI

2) How is cold-formed steel (CFS) different from hot-rolled steel?

CFS starts as sheet steel and becomes framing shapes through cold forming (that is, with no added heat). Hot-rolled steel typically becomes heavy structural shapes (like wide-flange beams) through high-temperature processes. CFS members are typically less than 1/8” thick and are manufactured with galvanized coatings for corrosion protection. Hot-rolled steel often has either no coating or a painted coating. Thicknesses range from ¼” to over 1”.

Learn more:

3) How do manufacturers make cold-formed steel (CFS) studs and track?

Manufacturers feed coils of sheet steel through roll-forming machines where dies or rollers shape the steel into C sections and other profiles. The process can produce shapes beyond studs and track, including U-, Z- and hat-shaped sections for specific applications. A key benefit of roll forming is that the CFS members can be made to any length.

Learn more:

4) Where do teams use cold-formed steel (CFS) framing in a building?

Teams use CFS framing for interior wall partitions (non-loadbearing walls), interior ceilings and soffits, flooring systems and exterior wall framing. They also use cold-formed steel framing in structural systems in many low- and mid-rise buildings.

The owner of this project substituted cold-formed steel (CFS) for poured-in-place concrete to create radiused columns, which saved project weight, time and money. Image credit: CEMCO

Learn more:

5) Is cold-formed steel (CFS) noncombustible?

Yes — BuildSteel highlights steel’s noncombustibility as a key fire-safety advantage during construction and after building occupancy.

Learn more:

6) Will cold-formed steel (CFS) framing rust or corrode?

Building codes mandate that structural CFS framing products use metallic-coated protective coatings (galvanized and similar) and designers match coating and detailing to exposure conditions.

Learn more:

7) Is cold-formed steel (CFS) framing sustainable? Does it contain recycled content?

CFS framing supports circularity because steel is the most recycled material on the planet. All cold-formed steel framing contains 25% or more recycled steel content.

Learn more:

8) What does a cold-formed steel (CFS) framing product designation like 600S162-43 mean?

The CFS alpha-numeric label 600S162-43 tells you what the member is (a stud, track or channel, for example). The designator also includes key dimensions and thickness so you can order and verify materials quickly.

The numbers in a CFS designator (600S162-43, e.g.) indicates the type of member (S for stud), the member’s web depth (600), flange width (162) and material thickness (43 mils).

Cold-formed steel (CFS) product labeling communicates industry certification, web depth, flange size, member type and thickness, which allows teams to order the correct framing components. Image credit: Marco Johnson

Web depth

- The first number in the designator (600) refers to the profile’s web depth. In the case of 600S162-43, the web depth classification number is 600 or 6″.

- Generally, depth is measured from the outside of the web. The exception is track, or “T” sections, where member depth is the inside-to-inside dimension. However, all CFS web depths are taken in 1/100th of an inch. Let’s say you’re ordering a 3-⅝” stud. That width equals 3.625”, which is approximately 362 x 1/100.” So, the designator would be 362.

- In the sample designator 600S162-43, the number 600 means the stud has a web depth of 6”.

Flange width

- Flange width (162) is the second number in the CFS designator, the first to occur after the profile letter. Like web depths, flange widths are measured in 1/100 inches.

- In the 600S162-43 sample, the number 162 designates a flange 162 x 1/100” wide, or 1-⅝”.

Thickness

- The number after the dash (43 mils) signifies material thickness. Unlike web depth and flange width, material thickness is measured in “mils.” Mils stands for 1/1000th of an inch.

600S162-43

Now take the example: 600S162-43. The nomenclature immediately indicates that it’s a 6” stud (600 x 1/100”). The stud has a 1-5/8” flange (162 x 1/100”) and a material thickness of 43 mils. This stud would be similar to a common 2” x 6” wood stud.

- Same size stud in a thinner material? 600S162-33 might work

- A thicker stud? Consider 600S162-54

Learn more:

9) What is STUFL in cold-formed steel (CFS) framing?

STUFL is a quick way to remember the most common CFS member families used on jobs:

Stud or Joist, Track, U channel, Furring channel and L header

Learn more:

10) How do I specify low embodied carbon (LEC) cold-formed steel (CFS)?

Start by defining what “low embodied carbon” means for your project (documentation, thresholds and verification). Then request the right product and reporting information.

With the growing demand for LEC steel, it’s easier than ever to specify LEC cold-formed steel (CFS) framing to reduce the environmental impact of their projects. Image credit: ClarkDietrich

11) How do I start a clean, AI-readable cold-formed steel (CFS) framing specification?

Use short, searchable requirements that separate structural versus nonstructural scope, define performance (heights, loads and deflection) and clarify submittals.

Learn more:

- Checklist for Architects and Engineers Writing CFS Specifications

- SFIA Releases Updated Cold-Formed Steel Guide Specs

12) What is delegated design? Should I use it for interior partitions?

Delegated design often suits structural framing, but teams should avoid using it for interior nonstructural partitions and ceilings.

Learn more:

- Delegated Design for Cold-Formed Steel Interior Framing

- SFIA Guide to the Performance-Based Nonstructural Partition Selection of Metal Framing (PB101-23)

A Missouri fire station switched from bar joists to Low Embodied Carbon cold-formed steel (CFS) framing to speed up construction and lower environmental impact. Image credit: Negwer Materials

Cold-Formed Steel (CFS) in 90 Seconds

Cold-formed steel (CFS) is a framing system made from sheet steel that manufacturers form at room temperature into studs, track and other shapes. You can use CFS in interior non-loadbearing partitions and in many structural applications such as exterior walls, floors and roofs. Teams choose CFS because it is durable, noncombustible and delivers consistent dimensions, fast installation and strong performance. If you want the simplest “what it is / where it goes / why it matters” overview, start with what cold-formed steel is and how to use it and then use the 5-minute crash course to connect the basics to jobsite success.

BuildSteel™ Recommended Resources

- What Is Cold-Formed Steel Framing and How Can I Use It?

- 5-Minute Crash Course on Metal Framing

- A Comprehensive Guide to Steel Framing

A modern home outside of Toronto featuring cold-formed steel (CFS) framing was designed to have a life expectancy of more than 100 years. Image credit: Life Drywall Systems

Cold-Formed Steel (CFS) vs. Wood Framing

People new to steel framing often ask, “Why switch from wood to CFS?” The answer depends on the project, but high-level differences come up often.

Where CFS often helps

- Fire risk: CFS is noncombustible, which supports fire-safety and risk planning. See steel for fire safety and insurance savings.

- Durability: CFS uses protective coatings, and codes require designers to address corrosion protection. See durability facts for CFS and the durability fact sheet PDF.

- Repeatability: CFS supports precision and consistent member shapes, which can reduce field improvisation. See six advantages of CFS.

Where you still need to plan carefully for either material

- Clear specs and details: A good outcome depends on good documents and the right expectations. BuildSteel’s CFS specifications checklist helps you avoid omissions that create RFIs.

- Correct scope: Always separate structural versus nonstructural framing in your approach. BuildSteel offers new codes and standards guidance.

BuildSteel™ Recommended Resources

- The Top 5 Reasons To Use Cold-Formed Steel Framing

- Don’t Get Burned: Steel for Fire Safety and Insurance Savings

- Building for Life: The Facts About Cold-Formed Steel & Durability

- Why Are We Still Building Homes Like It’s 1832?

Common Mistakes Teams Make — And How to Avoid Them

The mistakes below show up repeatedly when teams are new to steel framing. Fixing them early reduces RFIs and change-orders.

- Mixing structural and nonstructural requirements

Teams sometimes write one “metal framing” spec that tries to cover everything. Instead, separate structural framing from interior partitions . BuildSteel explains why this matters in Complying with New Codes and Standards for Cold-Formed Steel Framing. - Relying on vague specs instead of a checklist

A missing detail (such as deflection criteria, movement, submittal expectations, coating, etc.) can trigger multiple RFIs. Use BuildSteel’s Checklist for Architects and Engineers Writing CFS Specifications as your “don’t forget” tool. - Misusing delegated design for interior partitions

Delegated design can shift responsibility in ways teams do not expect — especially in nonstructural interior framing. BuildSteel defines delegated design and the risks in Delegated Design for Cold-Formed Steel Interior Framing. When you need a cleaner approach, use performance-based partition selection via PB101-23 guidance and the full PB101-23 report download. - Not learning member designations before ordering

If your team cannot read “362S162-33,” mistakes are more likely to happen. Start with BuildSteel’s ordering primer: Need to Order Cold-Formed Steel Framing? Start With This Simple Guide.

BuildSteel™ Recommended Resources

- Complying with New Codes and Standards for Cold-Formed Steel Framing

- Checklist for Architects and Engineers Writing CFS Specifications

- Delegated Design for Cold-Formed Steel Interior Framing

- Need to Order Cold-Formed Steel Framing? Start With This Simple Guide

Framing subcontractors install cold-formed steel (CFS) framing systems, following the details in approved documents.

Roles and Responsibilities Map

Who does what? Use this role map to keep coordination clean and reduce confusion on submittals.

- Architect: Defines intent, performance expectations and coordination requirements. Therefore, use a spec checklist like BuildSteel’s CFS specification checklist to avoid missing key criteria

- Structural Engineer: Defines structural design criteria and how the framing system supports loads and movement. Thus, stay aligned with modern standards and updates highlighted in BuildSteel’s codes and standards overview

- Contractor / Framing Subcontractor: Selects compliant materials, coordinates detailing and installs per approved documents. Therefore, learn the designation system so ordering and verification stay accurate using BuildSteel’s ordering guide

- Inspector / Building Official: Verifies installation matches approved plans at required inspection stages. Significantly, BuildSteel points to a field inspection mindset in its Building Official’s Guide

BuildSteel™ Recommended Resources

- Checklist for Architects and Engineers Writing CFS Framing Specifications

- Complying with New Codes and Standards for Cold-Formed Steel Framing

- Need to Order Cold-Formed Steel Framing? Start With This Simple Guide

- Building Official’s Guide to Cold-Formed Steel Framing

Key Definitions

- Cold-Formed Steel (CFS) Framing: Steel framing members made from structural-quality sheet steel formed into shapes by roll forming through dies or rollers at room temperature (no added heat). See What is CFS and how do I use it?

- Roll Forming: A manufacturing process that feeds steel strips through a series of dies or rollers to progressively form members such as studs, track and channels. See How Cold-Formed Steel is Made

- Stud: A vertical framing member used in walls

- Track: A channel-shaped runner used at the top and bottom of stud walls

- STUFL: A memory tool for five common CFS framing profiles: Stud, Track, U-channel, Furring channel and L-header (explained in BuildSteel’s ordering guide)

- Mils: A thickness unit where 1 mil = 1/1000 inch (commonly used in member designations). Therefore, learn designation basics in Need to Order Cold-Formed Steel Framing?

- Noncombustible: A material characteristic where the framing does not act as fuel in a fire; BuildSteel summarizes key points in Don’t Get Burned

- Corrosion Protection: Coatings and/or detailing strategies that protect steel where exposure could impair strength or serviceability. See BuildSteel durability guidance and the durability fact sheet PDF

- Delegated Design: When the design professional sets performance requirements and a contractor assumes responsibility for designing that element, based on contract language; see BuildSteel’s delegated design explainer

BuildSteel™ Recommended Resources

- Cold-Formed Steel Introductory Glossary

- Need to Order Cold-Formed Steel Framing? Start With This Simple Guide

- How Cold-Formed Steel is Made

Locate trusted cold-formed steel (CFS) products and service suppliers near you using BuildSteel’s ultimate steel framing resource.

Next Steps for Beginners

- Download: A Beginner’s Guide to Cold-Formed Steel Framing (PDF).

- Use a spec “cheat sheet”: Checklist for Architects and Engineers Writing CFS Specifications.

- Stay aligned with current codes and standards: Complying with New Codes and Standards for Cold-Formed Steel Framing.

- Search for products and providers: The BuildSteel Product and Provider Directory

About SFIA

The Steel Framing Industry Association (SFIA), a unique organization representing steel mills, coil coaters, stud and connector manufacturers, component fabricators, Cold-Formed Steel Engineers Institute (CFSEI) members, suppliers/distributors, contractors and others, provides members with exclusive access to technical cold-formed steel (CFS) framing services, including CFS certification, environmental product declarations, market data and analysis, technical design guides, specification review services, architectural services, the Steel Framing Learning Portal , the SFIA Awards and more. SFIA is an accredited ANSI Standards Development Organization. Follow SFIA on LinkedIn, Facebook, Instagram and X.