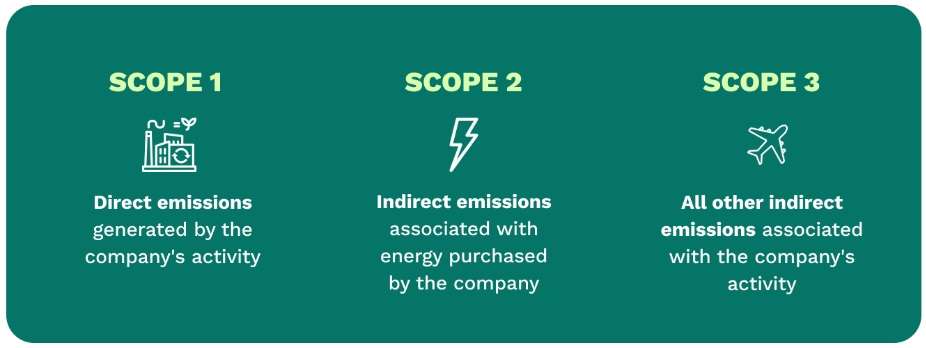

The built environment, which includes commercial and residential structures, contributes 40% of the world’s annual greenhouse gas emissions. Measured across the supply chain, these emissions are classified into three different scopes.

“Understanding these scopes is fundamental to improving sustainable practices and achieving reduction goals,” says the article “Demystifying Corporate Emissions: A Beginner’s Guide to Scope 1, 2 and 3” posted by Steel Framing Industry Association (SFIA) member ClarkDietrich. The release of the guide is well-timed, since building professionals are increasingly turning to cold-formed steel (CFS) to help mitigate these emissions and reduce on-site waste.

Here are some highlights from ClarkDietrich’s “A Beginner’s Guide to Scope 1, 2 and 3”:

Scope 1: Direct Emissions

Scope 1 covers greenhouse gas emissions from a company’s owned or controlled sources. According to the Global Reporting Initiative, this includes any physical unit or process that releases GHG into the atmosphere, such as CO2 emissions from fuel consumption.

At ClarkDietrich, Scope 1 emissions primarily stem from manufacturing processes (making use of natural gas, diesel and propane), company vehicles, welding gases and fugitive refrigerant leaking from air conditioning systems, says the article.

Organizations can reduce Scope 1 emissions by adopting electric vehicles and equipment and by capturing process and fugitive emissions through flues and ventilation systems.

The Environmental Product Declaration for Cold-Formed Steel (CFS) Framing — SCS-EPD-07103 (version Apr. 11, 2025) — is good through May 27, 2026.

The Environmental Product Declaration for Cold-Formed Steel (CFS) Framing from the Steel Framing Industry Association (SFIA) helps contractors, building owners, architects and others deliver advanced building designs that meet the latest LEED™ and other sustainable rating systems, programs and standards.

The SFIA EPD for CFS Framing can be seamlessly integrated into project specifications as an option with company-specific EPDs. SFIA offers a Specifications Review Service for this task. Architects and engineers can request a free SFIA specifications review for steel framing.

Scope 2: Indirect Emissions

Scope 2 emissions refer to an organization’s indirect emissions resulting from the generation of purchased or acquired electricity, heating, cooling and steam. Although these emissions occur at a third-party source, the consuming organizations are still held accountable since the emissions are being created by their demand for these resources.

ClarkDietrich’s energy is sourced from fossil fuel, nuclear and renewable power plants. According to the article, Scope 2 emissions are typically the easiest to measure and can be reduced by switching to renewable energy and improving overall energy efficiency.

CFS Meets All Sustainability Requirements

Cold-Formed Steel (CFS) meets the highest sustainability requirements set in all major green building standards and rating programs, including the Leadership in Energy and Environmental Design from the U.S. Green Building Council, the National Green Building Standard (ICC-700) for residential buildings, ASHRAE Standard 189.1 for commercial construction and the International Green Construction Code (IgCC).

The American Iron and Steel Institute reports:

- Steel framing contains a minimum of 25% recycled steel and is continually and completely remade without any loss of quality

- Most other construction products can only be down-cycled into lower-quality products

- Steel framing minimizes construction site waste

Scope 3: Indirect, Value Chain Emissions

Scope 3 emissions extend beyond an organization’s direct operations, capturing indirect emissions throughout its value chain, both upstream and downstream. These are emissions from purchased materials. Examples include outsourced manufacturing, business travel including air travel and the end of life disposal of products.

ClarkDietrich’s Scope 3 emissions primarily stem from purchased goods and services including:

- Water and sewer

- Waste disposal and recycling

- Business travel

- Employee commuting on-site or through telework

- Transportation of raw materials and finished products

Scope 3 is often the largest and most difficult to measure for most companies. Although much of it lies outside direct control, organizations can still reduce these emissions by partnering with lower-emission suppliers, designing products with their end of life in mind and clearly communicating responsible disposal practices.

A holistic focus on Scope 3 involves collaborating with suppliers, customers and employees to minimize environmental impact across the value chain, the ClarkDietrich article says.

Taking Action to Reduce Emissions

The steel framing industry, which includes ClarkDietrich, is dedicated to cutting greenhouse gas emissions. Industry members are improving their facility energy efficiency, investing in renewable power, collaborating with suppliers to lower emissions and creating products with reduced embodied carbon.

Steel framing customers can also help decrease Scope 3 emissions by choosing low-carbon products, recycling them at end of life and working with steel framing manufacturers, like ClarkDietrich, to combat climate change.

Additional Resources

- ClarkDietrich Wins SFIA ‘Sustainable Project’ Award for Acrisure Arena

- Steelmaking Innovations Support a Greener Future for Cold-Formed Steel Framing

- Building Owners Look to Steel for its Recyclability, Sustainability and Long Life