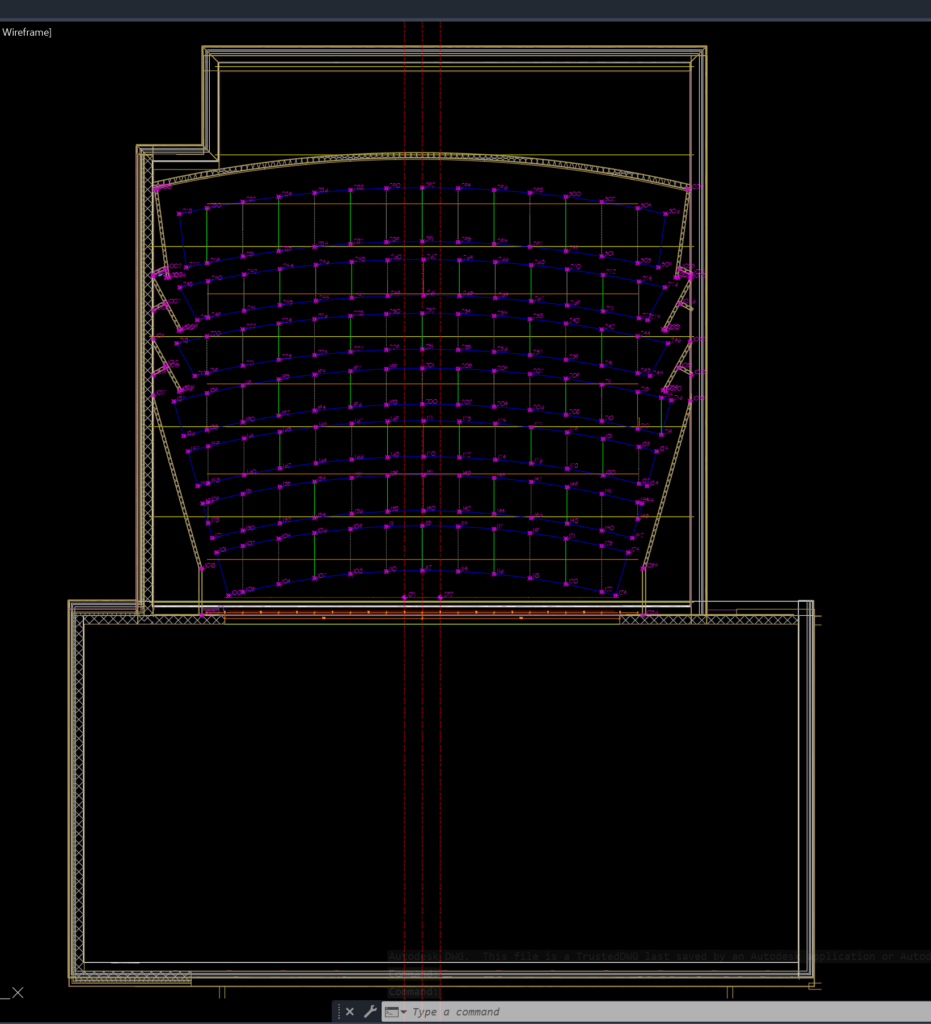

Images courtesy of James Hillegas of BIMTECH Offsite Prefabrication Solutions

So, you have a Building Information Modeling (BIM) or VDC team. You have them “bimming,” and everything seems great.

However, unless you can transition that pretty computer data to the field your BIM investment could be a wasted line item. It might not seem that way because it’s just a slower burn than lighting money on fire. Still, how do you get BIM data to the field? Answer: Layout tools.

There are many layout tools a company can purchase, ranging in the 5 figures and all the way up to 6 figures. Most of us have seen videos of the various robotic printers wheeling around a job site. While they’re interesting, it’s important to note that there are levels, or steps, to automated layout or CAD-assisted layout. Here are three of them:

1. Laser Layout Systems

The first layout tool is a laser system. One I have worked with is made by Spectra, which is not crazy complicated to set up. You have a tablet in your hands. Lasers cross at certain points in the field and mark points on the floor. Then, someone goes back and snaps chalk lines to those points on the ground.

Laser layout is typically a good entry point, relatively speaking. The cost is low to get started, and a CAD file is all that’s required.

My first experience with these systems came on a project at Gilmour Academy where, in a new auditorium, we had to install unistrut and aircraft cables 30 feet in the air to support a ceiling cloud. The cloud system was prefabricated with a drywall grid suspension and then hung in place.

The VDC team made it easy to execute:

James Hillegas’ layout file for installing unistrut and aircraft cables to support an auditorium drywall ceiling cloud.

A laser layout system made it easy to install the suspended drywall ceiling cloud in the auditorium at Gilmour Academy in Gates Mills, Ohio.

2. Robotic Total Stations

Robotic total stations are similar to laser layout systems. Various companies make a total station, which are typically more expensive than the laser systems. However, they function in much the same way.

The robotic part comes from the idea that the device will automatically turn and point you in the right direction with the laser on the floor. But again you still need someone to go back through and mark the chalk lines.

The total stations improve accuracy. This is critical because, as a company or a project team, dollars have been spent producing a model, and that design has been coordinated. The layout, the rough openings, the locations of various items have all been approved. Now you run the risk of having a chalk line snapped and based on a tape measure pulled incorrectly from a set of prints. Instead, you could use a total station to automate a portion of the layout with less risk of error — and in quicker time, as JBK ConTech reports show.

3. Robotic Printing

Fully automated robotic printing is provided by — as far as I’m aware — three companies in the United States. Each has different business models for how you get access to the software and the hardware, and it’s typically a large investment. You have to view the investment as justified by business more than by purely a ROI case.

Robotic printers are perfect for framing contractors. They are often the first to work a floor after it’s poured or after the shoring is removed. This presents framing contractors with a wide-open opportunity to leverage their dollars spent in BIM. They can layout walls in a fraction of the time with the closest solution to “no errors” that we have present.

As time passes robotic printing will become the standard, especially as crews who normally snap chalk lines will have less and less guys available to snap those lines.

Faster than Traditional Layout

Yes, it’s mostly agreed that using one of these three layout tools leads to faster results compared with doing layout in any other fashion. However, the procurement of the service and the hardware might provide a difficult business case in some instances for the framing contractor.

About BIMTECH Offsite

BIMTECH Offsite Prefabrication Solutions utilizes FRAMECAD, the world’s most advanced, end-to-end, cold-formed steel (CFS), engineer design and build system. This system gives the company the technical tools to accelerate the construction process, increase productivity, accuracy and reduce labor costs through offsite prefabrication of CFS wall panels, trusses and floor joists.

The Steel Framing Advantage

Cold-formed steel (CFS) leads the way as the preferred framing material for prefabricated structures for multiple reasons. CFS is:

- A pre-engineered material that can be cut to exact lengths

- Dimensionally stable and does not expand or contract with changes in moisture content

- Lightweight compared to wood and concrete

- Resilient and will not warp, split, crack or creep when exposed to the elements

- Sustainable and 100% recyclable

- Durable and has a high tensile strength

- Non-combustible and is a safeguard against fire accidents

Find CFS framing suppliers in BuildSteel’s industry wide Product and Provider Directory.

Additional Resources

- How to BIM: 3 Ways VDC Teams Can Bring Value to Projects

- How to BIM: Creating Your Team

- How to BIM: Choosing Software for Your VDC Team

- CFS Prefab 101: What is It All About?