BuildSteel is tracking the sustainability initiatives of Steel Framing Industry Association (SFIA) members and their partners. Here is some recent sustainability news related to the cold-formed steel (CFS) framing industry.

Cleveland-Cliffs Featured in DOE Climate Challenge Series

Cleveland-Cliffs Inc., an SFIA member, was recently featured in the U.S. Department of Energy’s Better Climate Challenge Road Show series. The series showcases real-world pathways for public and private organizations to decarbonize their buildings and plants.

As a partner in the Better Climate Challenge, Cleveland-Cliffs has committed to emissions reduction (scope 1 & 2) goals across its portfolio. In the DOE Road Show episode, viewers learn how Cleveland-Cliffs is leveraging its state-of-the-art direct reduction facility in Toledo, Ohio, and using other technologies to decarbonize its steelmaking operations.

“We are honored to be featured by the U.S. DOE in its Road Show series,” said Lourenco Goncalves, Cleveland-Cliffs’ chairman, president and chief executive officer. “Hot-briquetted iron consumption in our ironmaking furnaces is a proven real path forward to further reduce our carbon footprint while producing high quality steel for a more sustainable future.”

The Cleveland-Cliffs’ Toledo facility is considered the most modern and efficient direct reduction plant in the world. The facility is a hydrogen ready plant that produces hot-briquetted iron, an environmentally friendly alternative to scrap and imported pig iron used in the steelmaking process.

Read the complete news release.

U. S. Steel Pioneers Battery-Powered Locomotives

United States Steel Corporation, a leading steel producer and an SFIA member, announced the conversion of two of its diesel switcher locomotives at the Mon Valley Works’ Edgar Thomson and Clairton Plants to state-of-the-art battery-operated locomotives.

The locomotives, which carry steel, coke, scrap metal, iron ore and other materials necessary for production within the facilities, are expected to reduce airborne particulate matter emissions by .385 tons — the equivalent emissions of 7,000 gasoline-powered passenger vehicles.

“Mon Valley Works is the first industrial site to deploy this technology to reduce small particulate matter emissions from its locomotive fleet,” said Scott Buckiso, senior vice president and chief manufacturing officer at U.S. Steel. “Advancing our Best for All® strategy means producing solutions that benefit our customers and communities, people and planet.”

The switch to battery-powered locomotives will reduce the amount of diesel fuel consumed at the facilities by 40,000 gallons annually and demonstrate the company’s use of emerging technology to help reach the goal of achieving net-zero emissions by 2050.

Read the complete news release.

NUCOR to Develop 500 MW FUSION POWER PLANT

Nucor Corporation, a Charlotte, N.C., steel products manufacturer and SFIA member, announced a collaboration with fusion power company, Helion to develop a 500 MW fusion power plant.

This transformational project will offer baseload zero-carbon electricity from fusion directly to a Nucor steel making facility. Nucor and Helion are committed to beginning operations as soon as possible with a target of 2030.

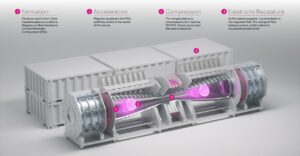

In Helion’s machines, plasmas are formed at both ends of the device, then accelerated by magnets into a compression chamber, where the plasmas combine and are compressed to fusion conditions. Electricity is directly recaptured in the process. Download a PDF fact sheet to learn more.

“Nucor continues to position itself as a leader in developing clean energy solutions to decarbonize the industrial sector,” said Leon Topalian, chair, president and chief executive officer of Nucor Corporation. “This agreement with Helion can change the entire energy landscape and forever change the world, embracing a clean energy future we could have hardly imagined a few years ago.”

Nucor is making a direct investment of $35 million in Helion to accelerate fusion deployment in the United States. This is the first fusion energy agreement of this scale in the world and will pave the way for decarbonizing the entire industrial sector.

Read the complete news release.

Additional Resources

- Update #13 | Sustainability News from ArcelorMittal Dofasco, U.S. Steel and Nucor

- Update #12 | Sustainability News from Nucor, U.S. Steel, and Steel Dynamics

- Update #11 | Sustainability News from Steel Dynamics, Cleveland-Cliffs and Carnegie Mellon

- Update #10 | Sustainability News from ArcelorMittal, U.S. Steel and Nucor

- Update #9 | Sustainability News from Nucor, Cleveland-Cliffs and U.S. Steel

- Update #8 | Sustainability News from FrameCAD, Cleveland-Cliffs and ArcelorMittal Dofasco

- Update #7 | Sustainability news from ArcelorMittal, SDI and U.S. Steel

- Update #6 | Sustainability news from Cleveland-Cliffs, Worldsteel and U.S. Steel

- Update #5 | News from Nucor, Cleveland-Cliffs and a New Low-Emissions Steel Coalition

- Update #4 | Steel Framing Industry Sustainability Initiatives

- Update #3 | Steel Framing Industry Sustainability Initiatives

- Update #2 | Steel Framing Industry Sustainability Initiatives

- Update #1 | Steel Framing Industry Sustainability Initiatives