BuildSteel is tracking the sustainability initiatives of Steel Framing Industry Association (SFIA) members and their partners. Here is some recent sustainability news related to the cold-formed steel (CFS) framing industry.

U.S. Steel Featured on ‘Inside the Blueprint’

United States Steel Corporation, a leading steel producer and an SFIA member, is featured in “Inside the Blueprint,” a B2B TV series airing nationally on Bloomberg TV. The series highlights groundbreaking innovations in commercial construction, design and engineering, showcasing products and technologies that transform the way people live, work and play.

The 30-minute episode highlights U. S. Steel’s role in American infrastructure, offering viewers an inside look at the steelmaking process and its commitment to sustainability, safety and how we serve customers in construction and other sectors.

“U.S. Steel is bridging the gap between tradition and future possibilities to meet the complex needs of modern infrastructure and industry,” says Dan Brown, senior vice president of Advanced Technology Steelmaking and COO of Big River Steel.

Steel Dynamics Sets New Carbon Reduction Targets

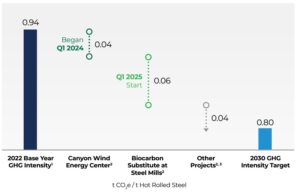

Steel Dynamics Inc., one of the largest steel producers and metals recyclers in the United States and an SFIA member, announced certified, science-based greenhouse gas emissions intensity targets for its steel mills. In alignment with the 1.5° C scenario set forth in the Paris Agreement, Steel Dynamics set a 2050 emissions intensity target of 0.12 metric tons of CO e per metric ton of hot rolled steel produced.

The company also set an interim 2030 emissions intensity target of 0.80 metric tons of CO e per metric ton of hot rolled steel produced, representing a 15% reduction, compared to the company’s 2022 base year.

To meet its carbon impact goals, Steel Dynamics will continue to:

- Identify and implement GHG emissions reduction projects

- Improve energy management to reduce GHG emissions and enhance operational efficiency

- Increase the use of renewable and nuclear energy, including partnering with utilities

- Research, develop, and implement innovative technologies

“Lower-carbon steel is necessary for the transition to a lower-carbon global economy,” says Mark D. Millett, chairman and chief executive officer at Steel Dynamics. “With these new targets and a proven track record of progress, we are demonstrating our commitment to continue making the steel required for a sustainable future.”

ClarkDietrich at the Forefront of EPDs

ClarkDietrich, a cold-formed steel (CFS) manufacturer and SFIA member, has been at the forefront of embracing Environmental Product Declarations to stay ahead of evolving regulations and drive sustainability-focused innovation in the CFS industry.

The company’s journey with EPDs began in 2014 when several large architectural and engineering firms informed the company that its products would no longer be specified without EPD documentation. The following year, ClarkDietrich issued its first EPD. Nearly a decade later, the company has expanded its EPD portfolio, now covering thousands of steel products, reinforcing its dedication to transparency and environmental stewardship.

One hundred percent of ClarkDietrich’s in-house produced cold-formed steel framing (CFS) products follow a low-embodied carbon Environmental Product Declaration.

“We aim to reduce our company’s impact on the environment, stay ahead of regulatory compliance and industry standards and let sustainability drive continuous improvement and innovation,” says Adam Shoemaker, director of corporate sustainability at ClarkDietrich.

Today, ClarkDietrich certifies 100% of its in-house produced cold-formed steel (CFS) framing products under a new low-embodied carbon EPD, according to the Green Builder Media. ClarkDietrich stands out as one of only two manufacturers in the CFS framing industry offering LEC products that qualify for General Services Administration projects in the top 20% tier. It is also the sole national-level provider.

Additional Resources

- Update #22 | Sustainability News from Cleveland-Cliffs, U.S. Steel and the Upcoming Green Steel Summit

- Update #21 | Sustainability News from the EPA, ResponsibleSteel and U.S. Steel

- Update #20 | Sustainability News from ClarkDietrich, ArcelorMittal and U.S. Steel

- Update #19 | Sustainability News from ArcelorMittal, Cleveland-Cliffs and Nucor4

- Update #18 | Sustainability News from U.S. Steel, Nucor and Cleveland-Cliffs

- Update #17 | Sustainability News from ClarkDietrich, Cleveland-Cliffs and U.S. Steel

- Update #16 | Sustainability News from Nucor, Cleveland-Cliffs and the U.S. General Services Administration

- Update #15 | Sustainability News from MRI Steel Framing, U.S. Steel and the U.S. Senate

- Update #14 | Sustainability News from Cleveland-Cliffs, U.S. Steel, and Nucor

- Update #13 | Sustainability News from ArcelorMittal Dofasco, U.S. Steel and Nucor

- Update #12 | Sustainability News from Nucor, U.S. Steel, and Steel Dynamics

- Update #11 | Sustainability News from Steel Dynamics, Cleveland-Cliffs and Carnegie Mellon

- Update #10 | Sustainability News from ArcelorMittal, U.S. Steel and Nucor

- Update #9 | Sustainability News from Nucor, Cleveland-Cliffs and U.S. Steel

- Update #8 | Sustainability News from FrameCAD, Cleveland-Cliffs and ArcelorMittal Dofasco

- Update #7 | Sustainability news from ArcelorMittal, SDI and U.S. Steel

- Update #6 | Sustainability news from Cleveland-Cliffs, Worldsteel and U.S. Steel

- Update #5 | News from Nucor, Cleveland-Cliffs and a New Low-Emissions Steel Coalition

- Update #4 | Steel Framing Industry Sustainability Initiatives

- Update #3 | Steel Framing Industry Sustainability Initiatives

- Update #2 | Steel Framing Industry Sustainability Initiatives

- Update #1 | Steel Framing Industry Sustainability Initiatives