The digesters at the Terminal Island Water Reclamation Plant in San Pedro, California, are iconic, egg-shaped structures built from post-tensioned concrete. Their original cladding had deteriorated significantly, and the city needed a replacement system. Specialty engineering firm McClure stepped in with a stainless-steel and cold-formed steel (CFS) solution.

McClure engineers selected a fully stainless-steel cladding, CFS-framed solution, which could deliver long-term performance in a harsh, high-corrosion coastal environment. This approach addressed the continuous moisture exposure inherent to wastewater treatment and the unique demands of the coastal site.

For its work, McClure won Second Place, Municipal category, in the 2025 CFSEI Design Excellence Awards. The Cold-Formed Steel Engineers Institute (CFSEI) presented the award. Lauren Gutknecht of McClure submitted the entry.

Featured image: Radiused stainless steel cladding on a digester in San Pedro, California. Profile courtesy of CFSEI. Images courtesy of McClure and Radius Track.

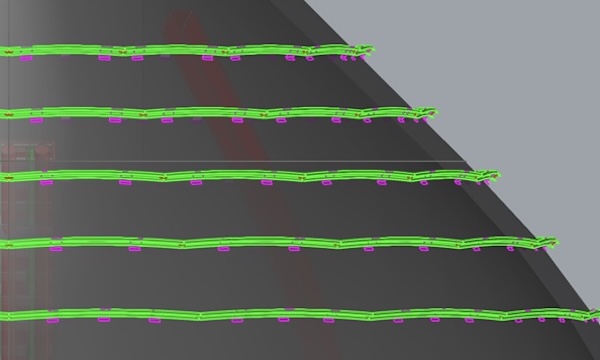

Field installation of the cold-formed-steel (CFS) framing and stainless steel cladding, showing vertical alignment and variable standoff conditions on the digester shell.

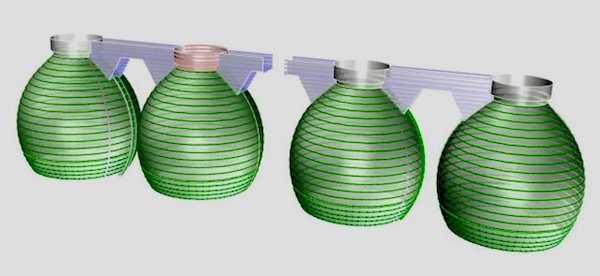

BIM model of the four digesters, illustrating the radiused cold-formed-steel (CFS) studs framing layout (in green) developed to support the cladding system.

Stainless-Steel + Cold-Formed Steel

The digesters’ egg-shaped geometry created major design hurdles. The new cladding needed to wrap a curved surface and adapt to unknown variations in the 50-year-old concrete substrate. The team also had to account for possible segmented or fully radiused conditions, inconsistent concrete thickness and variable anchor layouts.

To solve these issues, the design team created custom-fabricated, radiused stainless-steel horizontal studs. These studs resisted strong-axis, weak-axis, torsional and shear loading at the same time. The team formed the studs in short arc segments, which eliminated the need for doubly curved framing. This approach required rigorous 3D modeling and a careful review of testing data to confirm that each stud could handle the complex multi-directional forces.

Stainless-Steel Studs, Clips and Connectors

A fully stainless-steel framing system was essential for maximum service life. Even heavily coated carbon-steel components would corrode quickly in this environment. The design called for stainless-steel studs, screws, clips, anchors and connectors.

In locations spanning walkways, the team used straight stainless-steel furring to bridge varying distances back to the post-tensioned concrete shell. This detail provided flexibility where misalignments and inconsistent substrate spacing occurred.

The digester surface included many irregularities. The new cladding needed the ability to stand off from the concrete by six to nine and a half inches. The team developed custom clips attached to the stud webs, designing them with large tolerances and flat-plate bending to manage gravity loads.

Because the clips faced high flexural demands in their weaker axis, the design specified quarter-inch stainless steel to ensure strength and durability.

Existing post-tensioned concrete digester prepared for installation, with horizontal cold-formed-steel (CFS) studs attached to the curved surface.

3D model showing arced cold-formed-steel (CFS) studs used to create singly curved framing around the digester.

Anchorage Constraints and Field Testing

The post-tensioned shells introduced another challenge: The team didn’t know the concrete thickness until they removed the original cladding. Anchors had to remain shallow to avoid hitting reinforcement. Standard shallow anchors, however, couldn’t deliver the required capacities — especially under prying forces from long-reach clips.

The team performed on-site pull-out testing to generate accurate performance data. These tests confirmed that each anchor could resist design loads with minimal embedment.

The Adaptability and Resilience of CFS

By integrating radiused stainless-steel CFS framing, custom high-strength clips and field-verified shallow anchorage, the Terminal Island digester cladding replacement provides a robust, corrosion-resistant exterior. The design addresses the digesters’ complex geometry, uncertain existing conditions and large stand-offs required for the new stainless-steel cladding.

This project demonstrates the adaptability and resilience of cold-formed steel in highly specialized applications. It also sets a benchmark for long-lasting solutions in corrosive coastal and wastewater environments.

Read the complete story about the cold-formed steel (CFS) non-bearing panels and obtain the complete design diagrams for McClure’s 2025 CFSEI Design Excellence — Second Place — Municipal here.

Digester 3 with new stainless-steel cladding installed at the Terminal Island Water Reclamation Plant.

Terminal Island Water Reclamation Plant – Digester Cladding Replacement

Second Place, Municipal – 2025 CFSEI Design Excellence Awards

Winner: McClureJosh Garton (center) of McClure accepts the CFSEI Design Excellence Second Place award, Municipal category presented by CFSEI’s Immediate Past Chair Dana Hennis and Chair Tammy Gleed.

Project

Terminal Island Water Reclamation Plant – Digester Cladding Replacement

445 Ferry Street

San Pedro, California 90731Completion Date

2024People

Owner

City of Los AngelesArchitect of Record

ParsonsEngineer of Record for Structural Work

William Lu, P.E., ParsonsCold-Formed Steel Specialty Engineer

Josh Garton, P.E., S.E., McClureCold-Formed Steel Specialty Contractor

Jeff Montague, Radius Track

Additional Resources

- eBook: Specifying Cold-Formed Steel Framing: A Guide for Architects and Engineers

- Insights and Inspiration Take Center Stage at 2025 CFSEI Expo in Raleigh

- SFIA Reveals 7 Winners of the 2023 Industry Project Awards in Online Ceremony

- McClure wins CFSEI Award for Balcony Design at Titletown Residential Project Near Green Bay