Resilient channels are an essential component in construction, particularly for sound control and fire resistance. These channels play a vital role in improving the acoustical and fire performance of walls and ceilings in various building applications.

The Steel Framing Industry Association (SFIA) has released a guide entitled, “Four Frequently Asked Questions about Cold-Formed Steel (CFS) Resilient Channels” (RC101-24)*.

FAQs on Resilient Channels

Robert Grupe, SFIA general manager, architectural services, prepared “Four Frequently Asked Questions about Cold-Formed Steel (CFS) Resilient Channels” (RC101-24) for architects, designers, contractors and others to help them better understand the role of resilient channels on their projects.

SFIA RC101-24 is a free download that answers 4 frequently asked questions:

- What are resilient channels, and what is their purpose? (the subject of this post)

- Where are resilient channels installed?

- How are resilient channels installed?

- How do you hang wall cabinets off resilient channels?

Download SFIA RC101-24 to see the answers to all 4 FAQs.

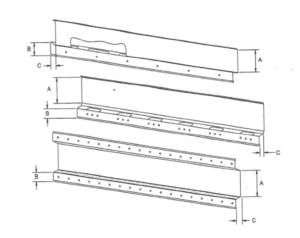

As SFIA RC101-24 notes, several resilient channel profiles can provide acoustical decoupling. Courtesy of Gypsum Association, GA 600 design manual.

What Are Resilient Channels?

Resilient channels are specialized metal profiles designed to enhance the acoustical and fire resistance properties of wall and ceiling assemblies. These channels are typically made from cold-formed steel (CFS) and have unique designs that allow for decoupling between the metal framing structure and the finish cladding, such as gypsum board.

Resilient channels are also called furring channels, metal hat channels or simply “hats.” They can be, and often are, rolled or brake-formed into several different sizes, depths and widths. Each manufacturer can provide the properties for the specific resilient channel member that you plan to use.

Resilient channels provide several functions in a building structure.

Purpose of Resilient Channels

1. Sound Control

One of the primary purposes of resilient channels is to improve sound control within a building. Sound transmission through walls and ceilings can be a significant concern, especially in multi-unit residential buildings, offices, or other spaces where privacy and noise reduction are essential.

Resilient channels are specifically designed to address the decoupling factor in sound control. When gypsum boards or other finish cladding materials are rigidly attached to the underlying framing, sound energy can be directly transmitted from one material to the next. This direct transmission of sound can result in poor acoustical performance.

To mitigate this issue, resilient channels provide an elastic connection between the framing and the finish cladding. This elasticity significantly increases the sound attenuation, meaning that it impedes the transmission of sound energy through the system. This enhancement in sound control is crucial for maintaining privacy and reducing noise pollution within a building.

Sound Transmission Classification (STC) is a rating system used to measure how effectively an assembly decreases sound energy transmission. A higher STC rating indicates better sound control. Resilient channels help assemblies achieve higher STC ratings, ensuring that sound energy is effectively reduced as it passes through walls and ceilings.

2. Fire Resistance

Resilient channels also find a niche in enhancing the fire resistance of building assemblies, particularly in floor-ceiling systems and wall assemblies. These channels can support the fire-resistive gypsum board ceiling membrane in various scenarios.

One common application is when a single layer of gypsum board is desired for fire resistance. Resilient channels can provide the necessary support for this gypsum board, ensuring that it remains intact during a fire event.

Additionally, in situations where multiple layers of gypsum board are needed to achieve horizontal membrane protection, resilient channels play a crucial role in supporting these layers. The channels help maintain the integrity of the gypsum board assembly, even under the stress of a fire.

Furthermore, the use of resilient channels reduces heat transfer through the assembly, which can be essential for fire resistance. By limiting heat transfer, these channels enhance the overall fire performance of the wall or ceiling assembly.

“Four Frequently Asked Questions about Cold-Formed Steel (CFS) Resilient Channels” is available for download.

Resilient Channel Profiles

Resilient channels come in various profiles, each designed to provide specific acoustical decoupling and fire resistance benefits. However, the fundamental principle remains the same: the channel is engineered so that only one attachment flange meets and is mechanically fastened to the supporting framing.

Architectural specifiers should carefully select the appropriate resilient channel profile based on the intended assembly and desired performance characteristics. Not all resilient channels are the same, and their effectiveness can vary based on their proprietary design.

In conclusion, resilient channels are a valuable addition to construction projects, serving as a critical tool for improving sound control and fire resistance in walls and ceilings. These channels play a pivotal role in creating quieter and safer living and working environments, making them an essential component in modern building design and construction.

Architects and builders should be mindful of the specific resilient channel profiles they specify to ensure optimal performance in their projects.

Robert Grupe

SFIA General Manager, Architectural ServiceRobert Grupe is general manager, architectural services at the Steel Framing Industry Association (SFIA), managing the SFIA’s Architectural Services Team nationwide. Grupe is a 40-year-plus industry veteran and popular seminar and webinar presenter. He spent over 38 years with United States Gypsum Company in various technical and management positions, including product and system design and technical consultation to the AEC community.

Steel Framing Industry Association

The Steel Framing Industry Association (SFIA) provides its members with exclusive access to technical cold-formed steel (CFS) framing services, including the SFIA Steel Framing Learning Portal. SFIA member services include access to market data, market analysis, technical design guides, architectural services, environmental product declarations, CFS certification , free specification review services and more.

Additional Resources

- SFIA Releases Guide to the Performance-Based Nonstructural Partition Selection of Metal Framing

- Sorting Apples from Oranges — Comparing Evaluation Services with Third-Party Certification

- SFIA Releases Updated Technical Guide with the Most Up-to-Date CFS Load and Span Tables in the Industry

- 5 Need-to-Knows about Building Codes and Cold-Formed Steel

* SFIA RC101-24 is intended as a general guide. The Steel Framing Industry Association has tried to ensure the accuracy of the information and makes no representation, warranty or guarantee, and expressly disclaims any liability or responsibility for failure resulting from use of this information. SFIA Certified products should only be used with an independent evaluation by a qualified engineer or architect to verify suitability.