Featured images courtesy of Dan Wies of Wies Offsite and its parent company, Wies Drywall and Construction Corp.

Recently, Dan Wies of Wies Offsite and its parent company, Wies Drywall and Construction Corp., a Steel Framing Industry Association (SFIA) member, produced and helped assemble the steel studs for an unusual structure.

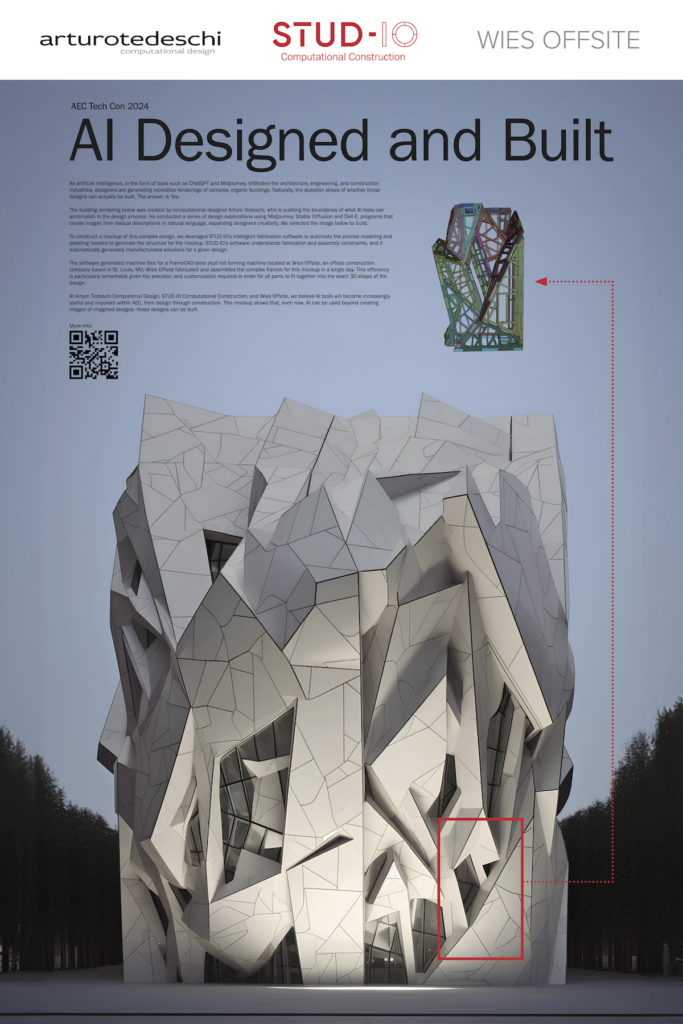

Wies collaborated with Scott Mitchell, founder of software developer STUD-IO, and computational designer and AI expert Arturo Tedeschi. Together, Wies, Mitchell and Tedeschi produced a three-dimensional, cold-formed steel (CFS) framed shape and in the process demonstrated the ease — and speed — with which such complexities can be produced.

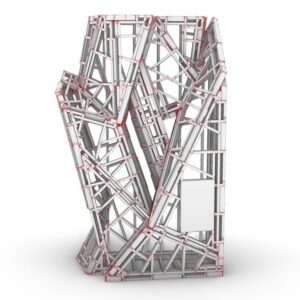

The technology behind Tedeschi’s design, Mitchell’s production files and Wies’s rolled CFS studs integrated to produce a 15-foot-tall mockup featured at AECTechCon, the two-day conference hosted by the Missouri chapter of the Associated General Contractors of America in St. Charles, Missouri, in May 2024. The exhibit sign attached to the mockup shows it to be one component of a building rendering designed by Arturo Tedeschi using artificial intelligence tools.

“The goal was to build something really neat to show what our roll-forming machines can do when paired with software that can do complex geometries,” Wies says.

Getting Crazy Geometries Correct

What looks like a piece of art — and what some say resembles a folded Optimus Prime transformer — is proof of concept that, when roll-forming machines are integrated with special computational software, a panel producer like Wies Offsite “can get crazy geometries correct,” Wies says.

“These machines can do much more powerful things than just rolling sticks,” Wies adds.

Using its roll formers from SFIA member FRAMECAD, the Wies Offsite facility produced 3 and 5/8th-inch, 30-mil studs with 1 and 5/8th inch flanges.

Wies said Mitchell’s STUD-IO software translated Tedeschi’s design into a production file in just one evening. The steel studs were roll formed the next day in Wies Offsite’s prefabrication facility.

The exhibit sign attached to the mockup shows it to be one component of a building rendering designed by Arturo Tedeschi using artificial intelligence tools.

The AECTechCon exhibit sign shows the mockup to be one component of a building rendered by Arturo Tedeschi using AI tools.

Assembling the 15-by-8-by-5-foot mockup in STUD-IO’s AECTechCon booth required three framers — Wies, Mitchell and another associate. The assembly consists of 27 separate panels, which were produced at Wies Offsite and shipped to the trade show. Assembling the 27 panels into the final mockup took just four hours.

Modus Operandi: Collaborative ConTech

The CFS-framed mockup at AECTechCon shows the value of collaboration, Wies says.

By combining Tedeshi’s complex design, Mitchell’s software and Wies’s roll-forming machines, construction manufacturers can frame complex designs efficiently for building owners and their design teams.

“I’m confident that one day an entire building will get built with this modus operandi,” Wies says.

The 27 separate cold-formed steel (CFS) framed panels produced by Wies Offsite ready to be moved to the AECTechCon trade show.

“As we continue to advance technology, and we continue to have bespoke manufacturers like Wies Offsite, we can create neat features in buildings or even entire buildings themselves, that would not have been possible ten years ago,” Wies says.

Wies says the possibilities for steel-framed designs are endless.

“If somebody wanted to put something really neat in their lobby, we could do it — something completely different — and we could cover it in drywall and tape it and have it be this neat artistic feature,” Wies says.

The cold-formed steel (CFS) framed panels produced by Wies Offsite lie on the AECTechCon show floor awaiting to be assembled.

Additional Resources

- CFS Prefab 101: What is It All About?

- Unraveling Modular Construction: Volumetric vs Panelized Approaches to Steel Framing

- SFIA’s Larry Williams Shares Insights on the Future of Construction and Technology on “Build It Better” Podcast