BuildSteel is tracking the sustainability initiatives of Steel Framing Industry Association (SFIA) members and their partners. Here is some recent sustainability news related to the cold-formed steel (CFS) framing industry.

ArcelorMittal Dofasco Publishes EPDs for XCarb™

ArcelorMittal Dofasco, Canada’s leading flat steel producer and an SFIA member, announced the publication of five Environmental Product Declarations for end use construction products using XCarb™, a recycled steel.

The EPDs allow customers to offer cladding, decking, roofing, cold-formed steel (CFS) sections and more with a low embodied carbon footprints.

“These EPDs certify that production on our Electric Arc Furnace generates the lowest embodied carbon sheet steel available in the North American market,” says Andrew Connor, VP Commercial at ArcelorMittal Dofasco.

ArcelorMittal’s XCarb™ RRP steel is made via the Electric Arc Furnace steelmaking route and contains a stated minimum of 70% scrap, with up to 90% scrap, and does not use carbon offsets to achieve the reduced carbon intensity.

Cleveland-Cliffs’ New GHG Emissions Reduction Goals

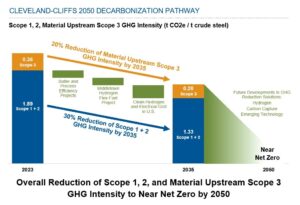

Cleveland-Cliffs, a flat-rolled steel producer in North America and SFIA member, announced it has set new greenhouse gas emissions reduction targets.

The company’s prior commitment to reduce absolute Scope 1 (direct) and Scope 2 (indirect) GHG emissions by 25% by 2030, relative to 2017 levels, has been achieved.

Cleveland-Cliffs’ new goals, relative to 2023 levels, are supported by ongoing and planned technological developments to its ironmaking and steelmaking practices. The goals include:

- Reducing Scope 1 and 2 GHG emissions intensity per metric ton of crude steel by 30% by 2035

- Reducing material upstream Scope 3 GHG emissions intensity per metric ton of crude steel by 20% by 2035

- Reducing Scope 1, 2 and material upstream 3 emissions intensity per metric ton of crude steel to near net zero by 2050

Cleveland-Cliffs’ new goals are supported by ongoing and planned technological developments to its ironmaking and steelmaking practices.

The GHG emissions reductions from 2023 to 2035 will be driven primarily by funding from the U.S. Department of Energy’s decarbonization investments in the Middletown Works facility in Ohio and the Butler Works facility in Pennsylvania.

Nucor, Google, Microsoft to Advance Clean Electricity

Nucor Corporation, a Charlotte, N.C., steel products manufacturer and SFIA member, announced they will work with Google and Microsoft across the electricity ecosystem to develop new business models and aggregate their demand for advanced clean electricity technologies.

These models will be designed to accelerate the development of first-of-a-kind and early commercial projects, including advanced nuclear, next-generation geothermal, clean hydrogen, long-duration energy storage and others.

Nucor, Google and Microsoft will work together across the electricity ecosystem to develop new business models and aggregate their demand for advanced clean electricity technologies.

According to the International Energy Agency, dispatchable clean electricity technologies and advanced energy storage systems are needed to cost-effectively decarbonize grids and help the world meet its growing electricity demand with carbon-free energy sources.

Advanced clean electricity technologies can fill gaps in wind and solar production and support grid reliability – needs still being met by fossil fuel generation.

Additional Resources

- Update #18 | Sustainability News from U.S. Steel, Nucor and Cleveland-Cliffs

- Update #17 | Sustainability News from ClarkDietrich, Cleveland-Cliffs and U.S. Steel

- Update #16 | Sustainability News from Nucor, Cleveland-Cliffs and the U.S. General Services Administration

- Update #15 | Sustainability News from MRI Steel Framing, U.S. Steel and the U.S. Senate

- Update #14 | Sustainability News from Cleveland-Cliffs, U.S. Steel, and Nucor

- Update #13 | Sustainability News from ArcelorMittal Dofasco, U.S. Steel and Nucor

- Update #12 | Sustainability News from Nucor, U.S. Steel, and Steel Dynamics

- Update #11 | Sustainability News from Steel Dynamics, Cleveland-Cliffs and Carnegie Mellon

- Update #10 | Sustainability News from ArcelorMittal, U.S. Steel and Nucor

- Update #9 | Sustainability News from Nucor, Cleveland-Cliffs and U.S. Steel

- Update #8 | Sustainability News from FrameCAD, Cleveland-Cliffs and ArcelorMittal Dofasco

- Update #7 | Sustainability news from ArcelorMittal, SDI and U.S. Steel

- Update #6 | Sustainability news from Cleveland-Cliffs, Worldsteel and U.S. Steel

- Update #5 | News from Nucor, Cleveland-Cliffs and a New Low-Emissions Steel Coalition

- Update #4 | Steel Framing Industry Sustainability Initiatives

- Update #3 | Steel Framing Industry Sustainability Initiatives

- Update #2 | Steel Framing Industry Sustainability Initiatives

- Update #1 | Steel Framing Industry Sustainability Initiatives