All images courtesy of CEMCO, an SFIA member.

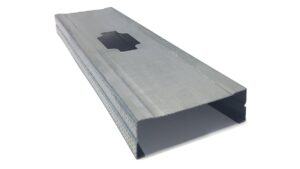

Over the past several decades, innovators in the steel framing industry have developed new methods to take the unique properties of steel and produce more competitive products. One of these products is EQ, or “equivalent,” cold-formed steel (CFS) studs for nonstructural framing applications.

EQ studs are the product of improvements in manufacturing technology, changes in stud profile designs and the use of higher strength steel. Today there are a wide variety of proprietary EQ studs on the market, accounting for 90% of all CFS studs sold in the United States, according to the Steel Framing Industry Association (SFIA).

“The members are roll-formed into the desired shapes in compliance with the AISI S100 Standard—Specification for Design of Cold-Formed Steel Members, producing individual cold-formed steel members with different mechanical, physical and structural properties,” writes Fernando Sesma, a member of CEMCO’s technical team, in a recent Walls & Ceilings article. CEMCO is an SFIA member.

What exactly are EQ studs? What is their history? How do designers, contractors and building owners benefit from their use?

Proprietary EQ studs account for 90% of all cold-formed steel (CFS) framing members sold in the United States.

History of EQ Studs

The history of the development of EQ studs can be traced back nearly 30 years. In 2000, the steel industry decided to standardize the CFS identification method and profile and introduced “mil” steel thickness, dropping the word “gauge” in its nomenclature for thickness.

According to Sesma, CFS manufacturers started to produce proprietary stud members in steel thicknesses less than defined in industry standard ASTM C645 and using non-conventional proprietary profiles.

Soon thereafter, the EQ stud concept of Equivalent in Performance was accepted by the industry and adopted in ASTM C645, Section 9.2.

EQ Studs vs. Conventional Studs

EQ studs have several key differences in comparison to conventional non-structural studs.

EQ Studs

- Are produced from a specific steel thickness less than the conventional minimum steel thickness of 0.0188 inches

- Have a yield strength greater than the standard 33 ksi used in the conventional non-structural standard stud

- Have a proprietary profile — by adding stiffeners, ribs, embossment, knurling and change in dimensions — designed to maximize its capacity, in addition to other mechanical changes

Saving With Steel

EQ studs are manufactured from thinner but stronger steel. When analyzing the data between EQ studs and conventional studs, the weight savings can be substantial with no compromise in performance.

Furthermore, when the numbers are translated into millions of feet and thousands of tons per year, the impact becomes significant.

Steve Farkas, director of business development at CEMCO, provided the following stud comparison to illustrate the environmental savings EQ studs can provide:

Comparing a standard 3-5/8” 30 mil (20 gauge) stud (362S125-30 ksi) with the ViperStud® (20EQ, 362VS125-18-70 ksi) produced by CEMCO, architects could help cut back on the amount of steel used on their projects by choosing the latter EQ stud.

“The amount of steel saved in producing products that meet the project’s specific design requirements is staggering,” Farkas writes.

Pounds of Steel Saved

* Data courtesy of CEMCO

The bottom line, nonstructural EQ framing products save steel while still satisfying design requirements.

Limiting Heights

A proprietary EQ stud having a different profile, steel thickness and steel yield strength compared with a similar conventional stud will have different allowable heights.

The tables below provide an example of the difference in allowable heights between two different metal studs, one an EQ and the other a conventional steel stud:

- A 3 5/8-inch and 6-inch-wide proprietary 20 EQ stud of 0.019-inch steel thickness

- A conventional 18-mil stud of 0.0188-inch steel thickness

20 EQ vs Conventional 3 5/8-inch Stud Allowable Heights

20 EQ vs Conventional 6-inch Stud Allowable Height

In the two examples presented above, the EQ studs offer higher limiting heights than the conventional studs.

“When identifying a specific EQ stud, it is important the EQ stud member be identified in mil thickness,” says Sesma.

Get the SFIA Product Technical Guide

The Technical Committee of the Steel Framing Industry Association (SFIA) has released Version 2023.1 of the SFIA Technical Guide for Cold‐Formed Steel Framing Products. The guide helps architects, engineers, specification writers and contractors who work with cold-formed steel (CFS) framing to comply with the latest building codes and standards.

The SFIA Product Technical Guide has the most up-to-date set of load and span tables available in North America. It meets the requirements of the 2021 International Building Code (IBC), the 2022 California Building Code and the 2020 Florida Building Code.

Additional Resources

- Why Are We Still Building Homes Like It’s 1832?

- EQ Metal Studs Help Designers Build Sustainable Structures

- Steel Framing Industry Offers 4 Tools to Help Reduce Construction’s Carbon Footprint