Images courtesy of James Hillegas of BIMTECH Offsite Prefabrication Solutions

Having set up your Building Information Modeling (BIM) team, you can now provide value to your customers. But how do you do this? What might get in the way?

It’s very common on the Internet to see photos of complicated and sophisticated BIM models. Initially, it doesn’t make sense why such complicated content is created. The designs seem impossible to execute, and their intent seems obscure. Frankly, many BIM models seem overly complicated. Why is that?

The answer is that many projects lack a true VDC team, one that can bring value to a project. Designers think in terms of engineering. But you need to think in terms of providing value. Allow me to explain.

How to Bring Value to a Project

When I went through my first coordination meeting, and I looked at a model with everything in it, I was overwhelmed by the details. I texted a colleague who responded, “It’s easy to understand where this comes from. Some engineers overdo things.”

My colleague helped me to see that my job as a BIM team leader is to look for solutions. Specifically, the goal of a VDC team is to bring value to cold-formed steel (CFS) framing designs.

A BIM team can provide value in a couple of ways. Here are 3 examples:

1. Provide Engineering of the More Expensive Parts of a Project

Your job is to assist with providing value. The VDC team confers with the lead designer, reviews the intricate details of the project and ties together all the different geometries into an elegant solution.

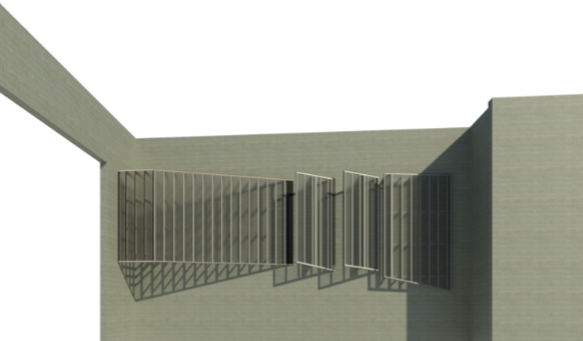

Here is example of the framing inside an auditorium that was complex to layout and prefabricate offsite. The VDC team made it easy to execute:

2. Provide a Cost-Effective Solution

It may not be clear how to do that after initially viewing the plans for a project. But by going through the process of BIMing (yes, that’s a verb), a VDC team can identify ways to save money while still achieving the architect’s desired look or design intent.

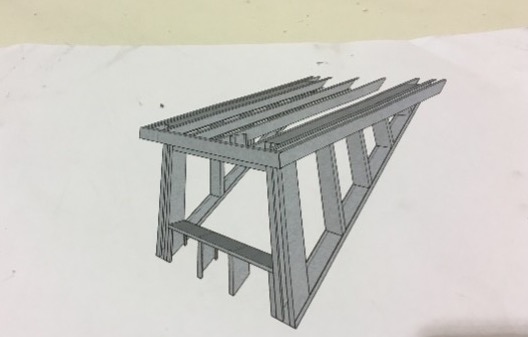

Here’s an example of a cost-effective VDC team solution – a prefabricated dormer:

3. Compress the Project Schedule

The VDC team achieves schedule compression by going through the plans and detailing out the areas that could create congestion.

It’s likely not necessary to review the whole scope of work, but just the areas in the plans lacking detail. It’s a good idea also to check areas that involve a degree of risk. Of course, the goal is to work towards detailing a full project.

Watch an example of how to compress a project schedule.

Focus on Benefits

A VDC team can provide a lot of value at the beginning stages of a project. The key is to avoid doing too much. Overcomplicating your models with sophisticated details may only lead to attempts to accomplish what’s not in the budget.

A better approach is to take a part of the project and detail what can be beneficial for that part. By doing this, your VDC team will bring value to their real-world projects.

About BIMTECH Offsite

BIMTECH Offsite Prefabrication Solutions utilizes FRAMECAD, the world’s most advanced, end-to-end, cold-formed steel (CFS), engineer design and build system. This system gives the company the technical tools to accelerate the construction process, increase productivity, accuracy and reduce labor costs through offsite prefabrication of CFS wall panels, trusses and floor joists.

The Steel Framing Advantage

Cold-formed steel (CFS) leads the way as the preferred framing material for prefabricated structures for multiple reasons. CFS is:

- A pre-engineered material that can be cut to exact lengths

- Dimensionally stable and does not expand or contract with changes in moisture content

- Lightweight compared to wood and concrete

- Resilient and will not warp, split, crack or creep when exposed to the elements

- Sustainable and 100% recyclable

- Durable and has a high tensile strength

- Non-combustible and is a safeguard against fire accidents

Find CFS framing suppliers in BuildSteel’s industry wide Product and Provider Directory.

Additional Resources

- How to BIM: Creating Your Team

- How to BIM: Choosing Software for Your VDC Team

- CFS Prefab 101: What is It All About?