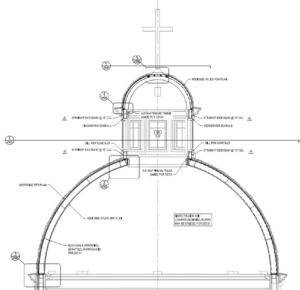

Featured image: The main dome at Blessed Stanley Rother Shrine was constructed prior to hoisting. Project profile provided courtesy of CFSEI.

The Blessed Stanley Rother Shrine is a two-story steel-framed church in Oklahoma City. The 40,000-square-foot structure displays ornate details, towers, clerestory windows, interior and exterior domes, interior barrel vaults and pendentive framing.

McClure received a first place 2023 CFSEI Design Excellence Award, municipal/cultural category, from the Cold-Formed Steel Engineers Institute (CFSEI) for its work in designing and detailing the structure’s framing schemes.

Dana Hennis (left), P.E., S.E. and CFSEI vice chair, and Kara Peterman (center), Ph.D. and CFSEI chair, present the first place award to Daniel Linneman of McClure.

Lauren Gutknecht of McClure submitted the Blessed Stanley Rother Shrine award entry to the CFSE Awards competition. Daniel Linneman of McClure accepted the award at the 2023 CFSEI Expo held recently in New Orleans.

Complicated CFS Curves

McClure’s scope was to assist Radius Track Corporation in the design and detailing of the complex curved framing of several of the church’s domes and interior framing.

- The main 40-ft.-diameter self-supporting dome supports an octagonal windowed cupola and secondary 11-ft.-diameter dome. The 11-ft. Dome in turn supports an 11-ft.-tall finial

- Two smaller 10-ft.-diameter self-supporting domes, which in turn are supported by 1-ft.-6-in. tall knee walls

- A 25-ft.-diameter half dome, with a diverging diameter interior dome, with horizontal support penetrating the brick cladding system

- Interior pendentive and arch framing to support decorative millwork

These complicated curved structures showcase McClure’s significant experience and expertise at curved cold-formed steel structures, pushing the limits and boundaries of cold-formed steel to solve complex and unique problems.

Main Dome Framing

The 40-ft.-diameter main dome is a cold-formed steel (CFS) self-supporting, load-bearing system. It consists of load-bearing crimped studs combined with a structural steel laser-cut steel plate circular tension ring and a laser-cut custom-curved structural steel built-up compression box ring.

The main dome posed several unique issues, most of which were related to cupola framing.

A Hollow Cupola

In order to meet architectural considerations, the cupola had to be hollow to allow the clerestory window light through the main dome. A traditionally framed dome would have center spokes to brace the interior of the compression ring against rotation and provide load transfer across the center of the dome from lateral loads.

Additional Cupola Loads

Another issue was that the cupola at the center of the dome has significant additional loads. The cupola finish system is 13,000 lbs. of solid stone in addition to the cupola weight.

The cupola’s lateral system has CFS window jambs with X-braced straps between the posts above and below the headers. This design added point loads to the compression ring, along with significant overturning forces on the compression ring.

To address this loading, the cupola has a structural steel built-up plate box compression ring to create torsional stiffness and better disperse the load between the individual stud ribs. This allowed the ribs to be cold-formed steel, which fully supports the nearly 18,000 lbs. of structure above. Thus, the entire dome structure (by weight) is 93% cold-formed steel.

RISA 3D Model

Both issues were accommodated by a fully detailed finite element model in RISA 3D.

RISA 3D model of the main dome shows the cold-formed steel framing elements. Plate elements are not shown for visual clarity.

The RISA 3D model evaluated the capacity of the framing members, including derating factors for crimped studs, the reduced moment of inertia of the crimped studs for deflection and the contribution of the plywood sheathing to the stiffness of the system for deflection evaluation.

Plate elements were used to apply loads that have the precise tributary areas on each member to produce the most efficient design.

Small Domes and Half Domes

The small domes were relatively traditionally framed but had the added complexity of hoisting the engineering included for the complex surface (again covered by a full finite element model in RISA 3D).

The complexity is that they sit on short straight walls that are separate from the dome system. They were designed similar to shear walls, using a 3D model to disperse the load. With the forces being relatively small, gypsum wallboards were utilized to support the lateral loads. Both small domes had cast stone finials they had to axially support, as well as the added horizontal loads.

Half Dome: Two Domes Together

The compression ring at the top of the half dome was not permitted to penetrate the brick finish. To laterally support the half dome, the interior finish dome was used, since it was a separate curved surface.

The two domes — the exterior and the interior finish dome — were then tied together vertically and laterally at the top so that the resultant thrust could be transferred at the center point of the half dome. A tension ring at the bottom acted as a vertical load distribution member, as well as a wind girt to transfer forces back to the structure.

The two domes — the exterior and the interior finish dome — were tied together vertically and laterally so that the resultant thrust could be transferred at the center point of the half dome.

Interior Pendentive

Many different directions and spans of CFS framing required complex coordination — 3D model coordination, detailed coordination of the surfaces and unique load paths and connection evaluation. A 3D finite element model was also made for these areas.

Read more here about McClure’s CFS details for the Blessed Stanley Rother Shrine, winner of the 2023 CFSEI Design Excellence Municipal/Cultural category.

Blessed Stanley Rother Shrine

700 SE 89th St.

Oklahoma City, OK 73149Completion Date

December 2022Construction Cost

$50 millionPEOPLE

Owner

Catholic Archdiocese of Oklahoma CityArchitect of Record

Arthur C. Lohsen, Frank & Lohsen ArchitectsEngineer of Record for Structural Work

David J. Oleynik, Spiegel Zamecnik & ShahCold-Formed Steel Specialty Engineer

Joshua Garton, P.E., McClureCold-Formed Steel Specialty Contractor

Carl Wedell, Radius Track Corporation

Additional Resources

- Cold-Formed Steel Helps Olympic Museum Rise and Twist

- CFSEI Announces Winners of 2022 Design Excellence and Creative Detail Awards

- Curved Cold-Formed Steel Framing in Fashion Center Receives Top Honor