The Nine31 Apartments at 931 University Avenue in Gainesville, Florida, rise 10 stories in cold-formed steel (CFS) framing above a three-story concrete podium. McClure joined the project as the CFS specialty engineer after podium construction and redesigned the CFS framing system to address quality issues and site-specific challenges.

For this work, McClure earned Third Place in the 2025 CFSEI Design Excellence Competition in the Residential/Hospitality category. The Cold-Formed Steel Engineers Institute (CFSEI) presented the award, with Lauren Gutknecht of McClure submitting the entry.

Featured image: The 931 University Avenue in Gainesville, Florida, features an interwoven cold-formed steel (CFS) shear walls. Profile courtesy of CFSEI. Images courtesy McClure.

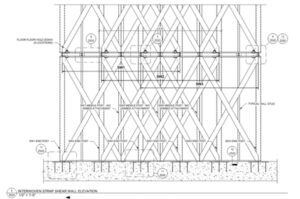

Overlapping cold-formed steel (CFS) shear walls reduced uplift reactions while accommodating existing podium embeds.

Embed Constraints and Shear Wall Design

Several design challenges emerged before the design process began. The team had already installed embeds for lateral reactions and uplift forces in the podium. The new design had to use existing embeds while limiting uplift reactions to 50 kips. This requirement prevented the existing podium structure from exceeding its load capacity.

The podium used post-tensioned concrete, which prevented post-installed embeds. Even with extensive shear wall use, maintaining reactions below 50 kips proved difficult.

The design incorporated overlapping shear walls to reduce reactions within embed limitations. Engineers modeled the system using a rigid diaphragm with relative stiffness distribution. This iterative process added and removed walls to distribute forces more evenly. Some embeds were ultimately used, while others remained unused. Most reactions fell well below 50 kips, though several remained near the limit.

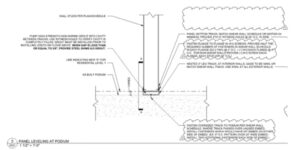

CFS Bearing Solutions for an Unlevel Podium Slab

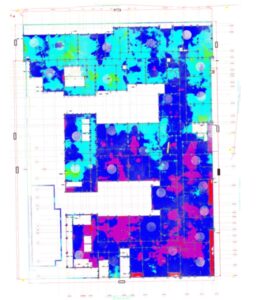

A second and more serious issue involved an unlevel podium slab. McClure initially lacked complete information on the slab condition. A later survey revealed elevation changes across the entire podium.

McClure performed a 3D survey before construction continued above the podium. The heat map showed the slab varied by up to 3 inches end to end. The framing required near-level bearing within the 1/8-inch CFS tolerance.

The team considered a traditional leveling slab but rejected it due to added dead load. At three inches, the slab would have added up to 40 psf. McClure designed an oversized track to create a level bearing surface. The track also served as formwork for flowable grout beneath the panels.

The installation followed a four-step process. Crews installed oversized tracks and slab fasteners to resist shear forces. They placed wood shims to level bearing wall panels. Installers fastened panels flange-to-flange within the oversized track. Crews injected flowable non-shrink grout to provide full bearing support.

Elevation heatmap showing podium slab variations, where green represents high elevations and blue represents low elevations.

Field Conditions and Constructability Solutions

Additional issues appeared after construction began. The earlier 3D scan allowed McClure to anticipate several conditions. Some shear wall end posts did not align with installed embeds. Other bearing walls overhung slab edges by as much as three inches.

McClure worked closely with the engineer of record to resolve these conditions. Crews added steel to support bearing walls and maintain continuous load paths. These solutions prevented overstress beyond allowable shear wall limits.

McClure collaborated closely with designers and contractors throughout construction. The firm developed numerous project-specific details under existing constraints. McClure analyzed shear wall forces, completed 3D scans, and engineered new details.

The team reduced embed forces and introduced overlapping shear wall strategies. They also created a new installation method for load-bearing walls on an unlevel podium slab. Without McClure’s cold-formed steel expertise, the Nine31 Apartments could not have been built.

The finished Nine31 Apartments stands complete and open following the successful integration of cold-formed steel framing.

Read the complete story about the CFS design used in the 931 University Avenue project. And see images from McClure 2025 CFSEI Residential/Hospitality Award win here.

Nine31 Apartments

Third Place – 2025 CFSEI Residential/Hospitality Award

Winner: McClureDaniel Linneman (center) of McClure accepts the CFSEI Residential/Hospitality Award, Third Place, presented by CFSEI’s Immediate Past Chair Dana Hennis and Chair Tammy Gleed.

Project

Nine31 Apartments

931 University Avenue

Gainesville, Florida 32601Completion Date

2024Construction Cost

$48 MillionPeople

Owner

CA VenturesArchitect of Record

Pierangeli Simonpietri, Dwell Design StudiosEngineer of Record for Structural Work

Daniel Roux and Luis Hasbun, E&M StructuralCold-Formed Steel Specialty Engineer

Jesse Barnes and Marcus Himmelberg, McClureCold-Formed Steel Specialty Contractor

Bruce Schierding, Eisen Group

Additional Resources

- Insights and Inspiration Take Center Stage at 2025 CFSEI Expo in Raleigh

- McClure Guides Complex Cladding Replacement at Terminal Island Plant, Wins CFSEI Award

- McClure Earns 2025 CFSEI Design Excellence Award for Fontainebleau Las Vegas