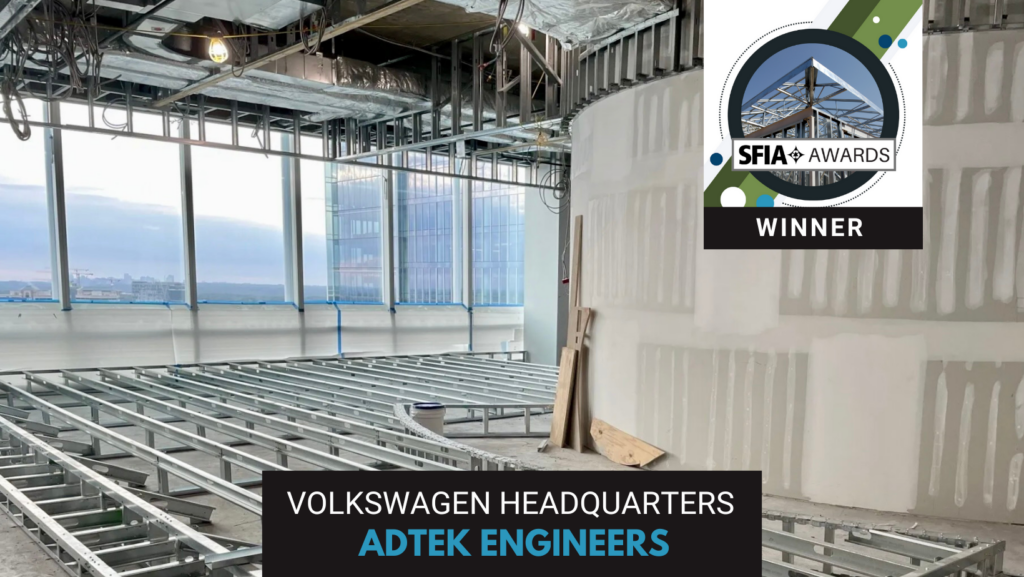

Featured image: Volkswagen headquarters in Reston, Virginia, features cold-formed steel (CFS) framing. Images courtesy of ADTEK Engineers.

Volkswagen Group of America established its new headquarters across seven floors of a newly constructed, state-of-the-art building in Reston Town Center, spanning 168,000 square feet of office and meeting space. A standout feature of the project is the trio of interconnecting staircases, including a striking curved stair with curved glass, a sleek shoe and robust steel plate guardrails. Each floor reflects the unique identity of Volkswagen’s diverse business groups, including Audi, Bentley and Bugatti. The spaces are framed using cold-formed steel (CFS) studs and track.

ADTEK Engineers, Inc., a member of the Steel Framing Industry Association (SFIA), designed the cold-formed steel (CFS) framing systems for the Volkswagen headquarters project.

ADTEK Engineers is the SFIA 2024 Industry Project Awards winner for the Volkswagen Headquarters project, winning in the Best Non-Load Bearing category. The SFIA Awards entry was submitted by Andrew Newland of ADTEK Engineers.

ADTEK Engineers’ win was announced at the 2024 SFIA Awards ceremony held live recently and posted online. The SFIA 2024 Industry Project Awards, an annual awards competition, focuses on CFS manufacturing and construction. This year, designers, manufacturers, distributors and contractors entered a variety of projects in the competition.

Design Quality

Did this project make efficient use of metal framing products?

This project was an interior renovation of floors 14 through 20 of an existing 20-story structure. The various levels included many unique features for which CFS was integral in accomplishing the architect’s design intent. The spaces included raised floors, stair plinths, clerestory support, seating and numerous different curved ceiling features. Different features were used throughout the space to create unique areas throughout.

The 2024 SFIA Awards judges said they “liked the curves and in the impressive interior created” using CFS.

Many of the architectural features of the Volkswagen Headquarters project are curved in various directions.

C.J. Coakley, the specialty subcontractor, panelized some steel stud soffit framing on the floor and raised the assemblies into place.

Installation Complexity

What difficulties existed on the project?

Dealing with existing construction posed problems. Installing free-standing framing on existing post-tensioned slabs proved exceptionally difficult. Without existing structural drawings or the original concrete contractor on hand, the location of post-tensioned cables was difficult to determine.

This project also had numerous glass clerestory partitions on top of free-standing CFS framing. The long runs and turns in the glass did not permit the installation of sills and jamb studs. With the use of ground penetrating radar, free-standing framing was able to be installed using proprietary rigid clips and anchors without the addition of structural steel or architectural modifications.

Installing free-standing cold-formed steel (CFS) framing on existing post-tensioned slabs required the use of ground penetrating radar.

The plinths and raised floors required cold-formed steel (CFS) tracks to be clipped and bent to create the curved features.

Manufacturing Complexity

Were special materials involved?

Many of the architectural features are curved in various directions. The plinths and raised floors required CFS tracks to be clipped and bent to create the curved features. Specialized curvable track was also used to create the curves. Similar details were used for portions of the ceiling where the ceiling curved in-plane. In other areas, curved studs were required to achieve the architectural intent. Proprietary curved framing was also specified to accomplish the needed radii.

In addition to unique architectural features, the existing building made transportation of the interior partition framing to the upper floors difficult. Proprietary adjustable, or telescoping, wall framing was used in lieu of standard steel stud framing with splices.

In other locations, the contractor panelized some of the steel stud soffit framing on the floor and then raised the assemblies into place.

The Volkswagen project had intricate interior architectural features, which the use of cold-formed steel (CFS) framing made possible.

The 2024 SFIA Awards winner for the Volkswagen headquarters project included SFIA members ADTEK Engineers, C.J. Coakley Co., Inc., ClarkDietrich, L&W Supply and Simpson Strong-Tie.

Overall Job Quality

How did the completed system turn out?

This project had very intricate interior architectural features, and the use of CFS framing made these features possible. The final project turned out extremely well.

ADTEK Engineers is the 2024 SFIA Awards winner in the Non-Load Bearing category for the Volkswagen headquarters project. The project also involved SFIA members C.J. Coakley Co., Inc., ClarkDietrich, L&W Supply and Simpson Strong-Tie.

Reston, VA

Details: 163.5 tons of cold-formed steel (CFS) used on the project

PEOPLE

Owner

Volkswagen Group of AmericaArchitect

GenslerEngineering Firm

Thornton TomasettiSpecialty Engineering Firm

ADTEK EngineersGeneral Contractor

DAVISCFS Specialty Contractor

C.J. Coakley Co., Inc.Other Providers

ClarkDietrich

L&W Supply

Simpson Strong-Tie.

SFIA Industry Project Awards

The SFIA 2024 Industry Project Awards focus on cold-formed steel (CFS) manufacturing and construction. A panel of industry representatives judged all 2024 SFIA Awards entries based on the following criteria:

- Design Quality, such as the efficient and sustainable use of CFS products

- Installation Complexity, focusing on conflict resolution, timeframe challenges, etc.

- Manufacturing Complexity, including custom orders, panelization, special material sourcing and more

- Overall Job Quality, including the quality of alignments, finishes and other attention to detail

- Conversion from Alternative Framing Material, reflecting how steel framing lowered a structure’s weight, or added stories, or helped lower the project’s builders’ risk insurance, etc.

About SFIA

The Steel Framing Industry Association (SFIA), a unique organization representing steel mills, coil coaters, stud and connector manufacturers, component fabricators, Cold-Formed Steel Engineers Institute (CFSEI) members, suppliers/distributors, contractors and others, provides members with exclusive access to technical cold-formed steel (CFS) framing services, including CFS certification, environmental product declarations, market data and analysis, technical design guides, specification review services, architectural services, the Steel Framing Learning Portal , the SFIA Awards and more. SFIA is an accredited ANSI Standards Development Organization. Follow SFIA on LinkedIn, Facebook, Instagram and X.

Additional Resources

- SFIA Unveils 9 Winners of the 2024 Industry Project Awards

- SFIA Reveals 7 Winners of the 2023 Industry Project Awards in Online Ceremony

- Designers: Update to SFIA’s 2024 Tech Guide for the Latest CFS Load and Span Tables