Image Credit: All Steel Mid-Rise

Is it possible to construct 20,000 square feet of steel floor decking in just 10 days? Can prefabricated steel wall panels be erected on time when the laydown area for them is tight? Yes and yes. This was the case at Nevele22 recently completed in Chicago.

Nevele22 is a 7-story mixed-use building, featuring 97 residential units with ground floor retail space, in the rapidly growing River West neighborhood of Chicago. SFIA member All Steel Mid-Rise’s cold-formed steel (CFS) structural wall panels and floor system were selected for the project. The prefabricated steel systems allowed the installers to erect the CFS frame on schedule despite a tight laydown area, saving time and money for the project.

Neighborhood Grows Up With Steel Framing

All Steel Mid-Rise’s cold-formed steel (CFS) structural wall panels and floor system frame the 7-story Nevele22 mixed-use building.

Nevele22, located at 1122 West Chicago Avenue, is a $33 million, 97,000 square foot mixed-use development that includes a two-story parking garage and 21,900 square feet of commercial space.

The influx of new residents and workers in River West is leading to increases in transit, pedestrian and bicycle traffic as single-story commercial structures are being upgraded with new mid-rise and high-rise buildings, according to real estate developer Lipe Property. Since 2016, more than 1,700 new residential units have either been completed or are breaking ground in the Chicago neighborhood.

All Steel Mid-Rise load-bearing wall panels and Timberless-44 prefabricated floor system were selected for the project by the ownership team of Global Builders. The prefabricated systems provided an efficient method to frame the project, leading to a faster construction schedule and revenue generation for the owners.

Metal Framing Ideal for Tight Laydown Area

At Nevelee22, CFS prefabricated floor and wall panels enabled the installers to work quickly despite having the small laydown area.

Nevelee22 sits on a triangular lot formed by the intersection of West Chicago Avenue and the diagonally-oriented North Milwaukee Avenue. The prefabricated floor and wall panels allowed the installers to erect the CFS systems on schedule despite the tight laydown area.

By using a prefabricated framing system, the steel panels were able to be brought onto the job site as needed. This reduced the amount of materials on site and streamlined coordination with other trades.

Steel Floor System Cuts Installation Time in Half

All Steel Mid-Rise constructed 20,000 square feet in 10 days using the Timberless-44 prefabricated floor system.

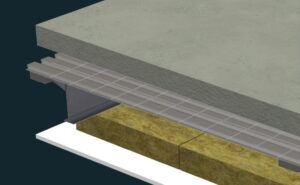

All Steel’s prefabricated Timberless-44 floor and decking system was ideal for the project. With joists at only 48″ on center, the steel system reduced labor and materials.

Using the prefabricated floor and decking system, All Steel was able to construct 20,000 square feet in 10 days, while the standard guideline for panels and floor system is 6,000 square feet a week.

The CFS system allowed for quicker dry-in, which is critical prior to the Chicago winter season. Once in place, the iSPAN TotalJoist portion of the Timberless-44 provided convenience for the MEP trades installation process with pre-drilled areas for quick installation.

The project was completed in August 2021.

The Steel Framing Advantage

Cold-formed steel (CFS) leads the way as the preferred framing material for prefabricated structures for multiple reasons. CFS is:

- A pre-engineered material that can be cut to exact lengths

- Dimensionally stable and does not expand or contract with changes in moisture content

- Lightweight compared to wood and concrete

- Resilient and will not warp, split, crack or creep when exposed to the elements

- Sustainable and 100% recyclable

- Durable and has a high tensile strength

- Non-combustible and is a safeguard against fire accidents

Additional Resources

- Panelized Steel Framing Keeps Mixed-Use Project on Schedule

- Steel Framing System Cuts Construction of 90-Unit Apartment Building by 75%

- CFS Prefab 101: No Need for a Big Factory