ClarkDietrich Releases Updated iTools

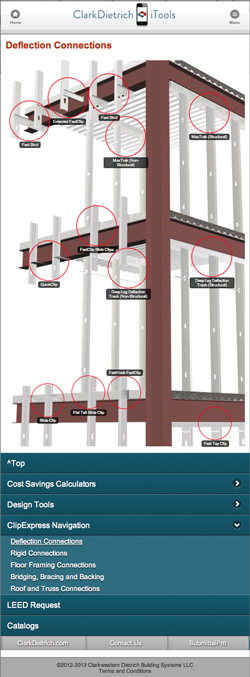

SFIA member ClarkDietrich released an updated version of its iTools app with design and navigation changes.

ClarkDietrich launched iTools in 2013 as a free online resource for architects and contractors. The desktop and mobile platform provides design lookup tools for steel framing projects including:

- ClipExpress products

- Cost calculators

- Sustainability tools

- Product submittals

ClarkDietrich launched iTools as a free desktop and mobile platform that provides design lookup tools for steel framing projects.

The updated version includes a new infrastructure, redesigned lookup tools and improved product navigation.

The tools now use dynamic filters and include a share button that generates a link to specific filtered results. The company combined two interior wall lookup tools into one tool and integrated it with BIMsmith Forge® to support 3D visualization and BIM development.

Users can view products in an interactive 3D model or switch to a standard product list. ClarkDietrich plans to add expanded navigation options, including Interior and Exterior Finishing Products.

The platform also includes Embodied Carbon Calculators for structural and non-structural steel-framed walls. These calculators help project teams compare standard and low embodied carbon steel options and evaluate carbon impacts.

Users can access the updated platform at itools.clarkdietrich.com. A tutorial video is available on YouTube.

Read the full news release from ClarkDietrich.

Scottsdale Mobile Roll Forming Video Series

SFIA member Scottsdale Construction Systems has launched the Roll Forming with ScotCyd video series to spotlight practical roll forming applications in cold-formed steel (CFS) framing construction. The series centers on a mobile containerized Scotpanel roll forming machine and follows Cydney Skeens as she guides viewers from digital modeling to full steel framing fabrication. It offers builders, fabricators and manufacturers insight into how CFS framing production adapts to various projects.

Roll Forming with ScotCyd, a video series from Scottsdale Construction Systems, spotlights practical cold-formed steel (CFS) roll forming applications.

Each episode connects digital design, fabrication and construction through real production scenarios. The containerized system features the Scotpanel 7090 housed within a standard shipping container, engineered for mobility without sacrificing performance. Electrical systems, controls and tooling integrate within the unit to enable rapid setup and consistent output. By deploying CFS fabrication directly to jobsites or regional hubs, the system reduces logistics challenges and strengthens scheduling control.

Throughout the video series, viewers see wall framing, roof panels, floor systems and other components produced with precision and repeatability. Skeens draws on her background in computer systems, manufacturing and steel framing to share best practices in machine setup, maintenance and operations. Her hands-on approach underscores how mobile steel stud roll forming enhances efficiency across a variety of projects.

“By focusing on real production, real challenges, and real solutions, the series advances understanding of steel framing fabrication while showing what’s possible when technology, mobility and precision come together,” says the Scottsdale article.

Read the full Scottsdale Construction Systems article.

U.S. Steel Expands with High Tech Steel Learning Mill

At United State Steel Corporation, an SFIA member, Big River Steel Works expanded with Big River 2. The company built the high tech learning mill to advance modern steelmaking. The facility operates on a simple principle – learn something new every day. BR2 pushes the boundaries of modern steelmaking and puts 60 terabytes of data to work each year. Automation and machine learning support engineers as they deliver high quality steel solutions tailored to customer needs in a safe and environmentally responsible manner.

The Endless Strip Process anchors this approach. As the first system of its kind in North America, ESP captures detailed production data and feeds it back into the line in real time. Each coil prompts automatic adjustments that refine performance. The mill produces hot rolled coils at thin gauges typically linked to cold rolled products. It maintains uniformity within each coil and across orders. Metallurgists, quality engineers and operations teams use these insights to strengthen steel consistency and precision.

BR2 extends this intelligence through hot autonomous coil storage that operates without human intervention. Automation reduces exposure to heat and sharp edges while limiting product damage. Integrated data systems connect production with order entry, supply chain management and scheduling. Advanced AI features analyze live production and business data to deliver real time insights. This approach improves efficiency and positions the expanded steel operation to anticipate challenges as it grows.

Read the full news release from U.S. Steel.

Additional Resources

- Update #6: T.J. Wies Redefines Hospital Prefab, Contractors Back Steel Growth, U.S. Steel Invests in the Future

- Update #5: U.S. Steel Upgrades, Nucor Mill Targets 2027 Launch, Startup Reinvents Housing

- Update #4: L&W Supply Expands in Oregon, CEMCO Adds ArcelorMittal’s Magnelis® Coating, ClarkDietrich Obtains Connector Certification

- Update #3: Grabber Introduces New Fastener, TSN Expands in Texas, ClarkDietrich Connector Reduces High-Rise Noise

- Update #2: CEMCO Reaches 50, FRAMECAD Unveils New CFS Platform, ClarkDietrich Adds Sustainability Glossary

- Update #1: BlazeFrame® Tape, Bridging Connectors and Steel-Framed Glass Curtain Walls