CFS Framing Enhanced by 3D Printed Connectors

Researchers at the University of Aberdeen have developed advanced 3D printed metal connectors to improve cold formed steel (CFS) framing for residential construction. The project integrates manufacturing with engineering to make buildings easier to assemble while reducing construction waste. Aberdeen’s researchers combined CFS framing expertise and digital fabrication to create connectors that can be reused rather than demolished at the end of a building’s lifecycle, advancing sustainable building practices.

University of Aberdeen researchers developed 3D-printed metal connectors that enhance cold-formed steel framing performance and constructability.

The Aberdeen team focused on high-precision connectors that work with CFS framing sections typical in housing. By printing directly onto thin substrates, the researchers overcame distortion and stress challenges.

“This approach is entirely new,” says Dr Alireza Bagheri, senior lecturer in engineering at the University of Aberdeen. “No existing construction system currently combines metal 3D-printed connectors with cold-formed steel to enable rapid, automated assembly and complete disassembly for reuse.”

The researchers collaborated with Politecnico di Milano and combined prototyping, finite element modeling and full-scale testing. The connectors replace traditional mechanical connections. They allow for rapid assembly and complete disassembly without damage to structural parts.

The innovation offers a scalable alternative to conventional building systems, promising reduced material waste, greater adaptability and longer building lifespans with lower environmental impact.

ClarkDietrich Releases Updated iTools

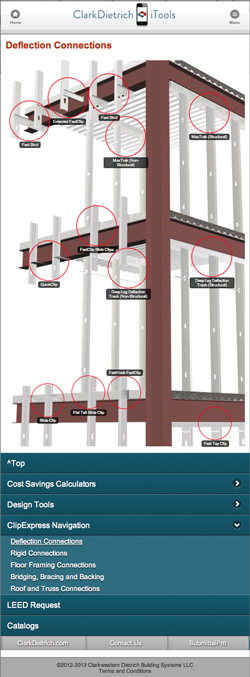

SFIA member ClarkDietrich released an updated version of its iTools app with design and navigation changes.

ClarkDietrich launched iTools in 2013 as a free online resource for architects and contractors. The desktop and mobile platform provides design lookup tools for steel framing projects including:

- ClipExpress products

- Cost calculators

- Sustainability tools

- Product submittals

ClarkDietrich launched iTools as a free desktop and mobile platform that provides design lookup tools for steel framing projects.

The updated version includes a new infrastructure, redesigned lookup tools and improved product navigation.

The tools now use dynamic filters and include a share button that generates a link to specific filtered results. The company combined two interior wall lookup tools into one tool and integrated it with BIMsmith Forge® to support 3D visualization and BIM development.

Users can view products in an interactive 3D model or switch to a standard product list. ClarkDietrich plans to add expanded navigation options, including Interior and Exterior Finishing Products.

The platform also includes Embodied Carbon Calculators for structural and non-structural steel-framed walls. These calculators help project teams compare standard and low embodied carbon steel options and evaluate carbon impacts.

Users can access the updated platform at itools.clarkdietrich.com. A tutorial video is available on YouTube.

Read the full news release from ClarkDietrich.

Scottsdale Mobile Roll Forming Video Series

SFIA member Scottsdale Construction Systems has launched the Roll Forming with ScotCyd video series to spotlight practical roll forming applications in cold-formed steel (CFS) framing construction. The series centers on a mobile containerized Scotpanel roll forming machine and follows Cydney Skeens as she guides viewers from digital modeling to full steel framing fabrication. It offers builders, fabricators and manufacturers insight into how CFS framing production adapts to various projects.

Roll Forming with ScotCyd, a video series from Scottsdale Construction Systems, spotlights practical cold-formed steel (CFS) roll forming applications.

Each episode connects digital design, fabrication and construction through real production scenarios. The containerized system features the Scotpanel 7090 housed within a standard shipping container, engineered for mobility without sacrificing performance. Electrical systems, controls and tooling integrate within the unit to enable rapid setup and consistent output. By deploying CFS fabrication directly to jobsites or regional hubs, the system reduces logistics challenges and strengthens scheduling control.

Throughout the video series, viewers see wall framing, roof panels, floor systems and other components produced with precision and repeatability. Skeens draws on her background in computer systems, manufacturing and steel framing to share best practices in machine setup, maintenance and operations. Her hands-on approach underscores how mobile steel stud roll forming enhances efficiency across a variety of projects.

“By focusing on real production, real challenges, and real solutions, the series advances understanding of steel framing fabrication while showing what’s possible when technology, mobility and precision come together,” says the Scottsdale article.

Read the full Scottsdale Construction Systems article.

Additional Resources

- Update #6: T.J. Wies Redefines Hospital Prefab, Contractors Back Steel Growth, U.S. Steel Invests in the Future

- Update #5: U.S. Steel Upgrades, Nucor Mill Targets 2027 Launch, Startup Reinvents Housing

- Update #4: L&W Supply Expands in Oregon, CEMCO Adds ArcelorMittal’s Magnelis® Coating, ClarkDietrich Obtains Connector Certification

- Update #3: Grabber Introduces New Fastener, TSN Expands in Texas, ClarkDietrich Connector Reduces High-Rise Noise

- Update #2: CEMCO Reaches 50, FRAMECAD Unveils New CFS Platform, ClarkDietrich Adds Sustainability Glossary

- Update #1: BlazeFrame® Tape, Bridging Connectors and Steel-Framed Glass Curtain Walls