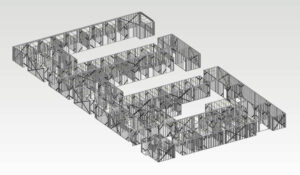

Featured image: Model of the steel framing for the “pods” used at Advocate Aurora Health Clinic in Lake Villa, Illinois. Project profile courtesy of CFSEI. All photos courtesy of R.A. Smith, Inc.

The Advocate Aurora Health Clinic in Lake Villa, Illinois is a 20,000-square-foot single-story load-bearing building. The project consisted of load-bearing cold-formed steel (CFS) walls with CFS roof trusses. It included a front entry that was constructed with structural steel and CFS bypass wall studs.

The uniqueness of this project comes from the method of construction. “Pods” were built that included the CFS load-bearing studs and interior non-load-bearing wall studs. CFS roof trusses were also panelized in much the same manner to preinstall the roof diaphragm, which included some of the MEP.

Dana Hennis (left), P.E., S.E. and CFSEI vice chair presents the CFSEI award to Brian Skupien of R.A. Smith.

R.A. Smith, Inc., an SFIA member, won the 2023 CFSEI Design Excellence Award for the project, taking third place in the municipal services category in the Cold-Formed Steel Engineers Institute’s award competition.

The CFSEI Award entry was submitted by Brian Skupien of R.A. Smith. Skupien also accepted the award for the Advocate Aurora Health Care project at the 2023 CFSEI Expo held recently in New Orleans.

Pods Built Off Site

The CFS load-bearing and non-load-bearing framed pods were built off site. The pods were partially finished and included MEP, drywall, paint and some cabinetry. They are then shipped to the job site and lifted into place with a crane.

The building was separated into four bays with double load-bearing walls between each bay. The bays varied in width from 29 feet to nearly 56 feet.

R.A. Smith separated the Advocate Aurora Health building into four bays with double load-bearing walls between each bay.

The project had many challenges. Here are a few of those challenges.

Trade Coordination

One challenge involved coordinating the trades top handle framing and installation of the room pods, along with other considerations related to erecting the wall systems.

Flat Strapping

Additional flat strapping was installed at the corners and lifting points as well as increasing the top and bottom tracks of the room pods.

Unique Detailing

And some additional, unique detailing was required. For example, since the drywall was preinstalled, the typical base detail with PDFs connecting to concrete had to be modified. The pods also had to be connected to adjacent walls and adjacent pods.

Roof Diaphragm Continuity

One of the more challenging aspects of this project was creating continuity in the roof diaphragm.

Since the roof trusses were panelized in 10’-0”-wide panels, in each of the four bays, load had to be transferred between each roof panel and into the X-braced walls. A combination of flat strapping and tracks was used to connect the roof panels together and transfer the load between them.

Prototype for Other Projects

The pods vary in size, with most containing two or three rooms. The largest is about 400 square feet (40 feet long x 10 feet wide). The pods typically included both load-bearing walls and non-load-bearing partition walls.

The CFS load-bearing and non-load-bearing components, engineered by R.A. Smith, were built off site and lifted into place with a crane.

The pods, which came with pre-hung cabinetry, had to be connected to adjacent walls and adjacent pods.

Since the load-bearing walls were part of the pods, the X-braced walls had to be designed and located to fit within a single pod’s dimensions. This created a challenge to locate and fit X-braced walls correctly. This challenge/design consideration would not have been present if the structure were built in the traditional stick framed method.

The project was also a prototype. It is intended to be the first of many nearly identical structures that Aurora Health wants to build.

- The design/build method of constructing the pods and shipping them to the site greatly sped up the construction timeline

- Keeping the future buildings similar to this prototype will reduce project timelines and cost

Read more about R.A. Smith’s CFS detailing for Advocate Aurora Health Care Clinic in Lake Villa, Illinois here.

Advocate Aurora Health Care Clinic, Lake Villa , Ill.

700 Park Avenue

Lake Villa, IL 60045PEOPLE

Owner:

Advocate Aurora HealthArchitect of Record:

Joshua Christensen, HDR ArchitectureEngineer of Record for Structural Work:

Andrew Shaw, IMEG Corp.Cold-Formed Steel Specialty Engineer:

Brian Skupien, R.A. Smith, Inc.Cold-Formed Steel Specialty Contractor:

George Dombeck, The Rockwell Group

Additional Resources

- R.A. Smith Wins CFSEI Award for Hybrid Steel Design at Luxury Chicago Apartment Building

- R.A. Smith Wins CFSEI Design Excellence Award for Office Building at Ovation

- SFIA’s Pat Ford Receives Distinguished John P. Matsen Award from CFSEI