Each month, the Cold-Formed Steel Engineers Institute (CFSEI) publishes answers to questions about the design of cold-formed steel (CFS) framing, which it receives through its 1-800-79STEEL hotline. “Ask an Expert,” the name of this series of frequently asked questions, can be accessed at CFSEI’s FAQ of The Month web page.

CFSEI Hotline

1-800-79STEEL

Clip Angle Design

Recently, CFSEI’s “Ask an Expert” responded to this question: Does AISI D114, Clip Angle Design Guide, require consideration of prying action when evaluating the anchored leg of a clip angle?

Does AISI D114, Clip Angle Design Guide, require consideration of prying action when evaluating the anchored leg of a clip angle?

Answer

AISI D114 provides design guidance based on both a strength limit state and a deflection limit state for clip angles subject to tension.

Traditional limit states associated with prying action are:

- Bending failure of the connecting element (e.g., anchored clip leg)

- Tension failure of the fastener

However, a University of North Texas study on thin screw attached clips identified two additional strength limit states. Both are addressed in AISI D114:

- Pull-over of the anchored clip angle leg (Fig. 1)

- Pull-out of the screw from the base material

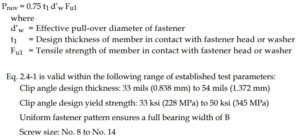

The pull-over strength limit state, Pnov is defined as:

The pull-over strength design equation was calibrated to test results. Thus, any prying effects are included in the design equation. Therefore, prying effects need not be considered.

However …

For the pull-out strength and screw tension strength evaluations, the prying effects should be considered.

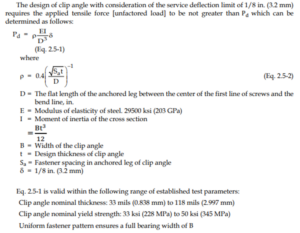

The D114 deflection limit state is as follows:

Based on the UNT testing, for thicker clip angles, the 1/8” deflection limit was achieved prior to a failure of the clip angle. Thus, when applying the AISI D114 design methods because a deflection limit is imposed for clip angles thicker than 54 mils the traditional prying action limit states are not a design consideration.

However, if the 1/8” deflection limit is not imposed as a design limit state, then prying action should be considered when evaluating the following limit states:

- Bending failure of the connecting element (e.g., anchored clip leg)

- Tension failure of the fastener

- Pull-over of the anchored clip angle leg

- Pull-out of the fastener from the base material

Ask an Expert

If you have any cold-formed steel (CFS) questions, contact CFSEI experts online or call CFSEI Hotline at 1.800.79STEEL.

Read more Ask an Expert questions and answers here:

CFSEI Hotline

1-800-79STEEL

1-800-79STEEL

The CFSEI Hotline from the Cold-Formed Steel Engineers Institute receives inquiries about cold-formed steel (CFS) applications. Architects, engineers, building officials, students and contractors needing answers from respected experts can check “Ask an Expert” on the CFSEI website or call 1-800-79STEEL.

CFSEI is part of the Steel Framing Industry Association (SFIA), where its leadership as the industry’s key touchpoint for CFS design receives full support.

Additional Resources

- SFIA Releases Guide to the Performance-Based Nonstructural Partition Selection of Metal Framing

- SFIA Releases Updated Technical Guide with the Most Up-to-Date CFS Load and Span Tables in the Industry

- 5 Need-to-Knows about Building Codes and Cold-Formed Steel