The Cleveland Clinic in Cleveland, Ohio, recently installed fully furnished, 10,000-pound modular research lab pods. R.A. Smith, Inc. designed the pods to be built off-site using cold-formed steel (CFS) framing. R.A. Smith earned a 2025 CFSEI Design Excellence award for the CFS framing design and pod system.

As part of the 2025 CFSEI Awards, R.A. Smith won the Design Excellence — Third Place honor, Commercial category. The Cold-Formed Steel Engineers Institute (CFSEI) presented the award. Alyssa Pease of R.A. Smith, Inc., submitted the entry to the competition and accepted the award.

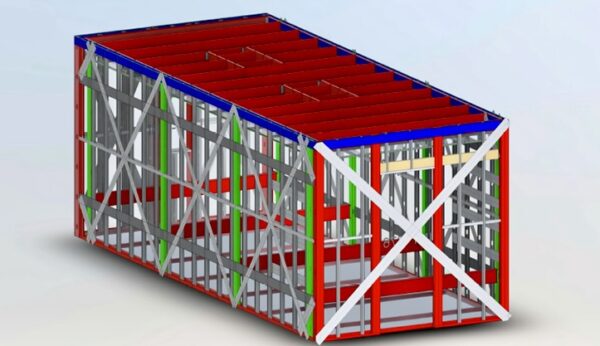

Featured image: A cold-formed steel-framed pod rises at the Lerner Research Institute, Building CBB, Cleveland Clinic, Cleveland, Ohio. All images courtesy of R.A. Smith and R.G. Construction. Project profile courtesy of CFSEI.

R.A. Smith engineered the cold-formed steel (CFS) framing for the free-standing pods and ensured each unit could be safely lifted, rolled into position, and securely anchored.

Modular Research Lab Pods

Trucks transported the fully furnished steel framed pods to the job site. Cranes lifted them to the second floor and rolled into final position with precision. R.A. Smith’s designers engineered the pods for strength and stiffness to protect interior finishes during movement. The pods maintained their structural integrity throughout the transportation and installation process.

R.A. Smith collaborated with the Cleveland Clinic to overcome engineering challenges and develop an effective design and approach for off-site construction.

SFIA member R.A. Smith played a pivotal role in the groundbreaking project. The firm’s designers engineered the CFS framing for the free-standing pods and verified that each unit could be safely lifted, rolled into position and anchored. The pods were fully furnished prior to transport, an important detail that increased the overall weight. This added to the engineering challenge, making it essential to limit deflections and maintain a stiff structure to prevent interior drywall cracking during movement.

The project entailed designing the lifting connections and the load transfer mechanism. It also included developing solutions for moving and anchoring the pods in place. This level of involvement required seamless coordination between R.A. Smith and R.G. Construction, the CFS specialty contractor, along with an open-mind and flexible approach to challenges. During the planning phase, numerous strategies were explored, ultimately leading to the development of a cost-effective solution for moving and securing the pods.

How to Move 10,000-Pound Modules

The project’s success relied on overcoming several engineering challenges. R.A. Smith collaborated closely with the Cleveland Clinic to determine the most effective approach for constructing the modular labs off-site, transporting the units, lifting them into place and rolling each into final position.

Section 13/CF2.3 — a designation used in structural steel components where a frame will be lifted or moved — was critical to ensuring the safety and stability of the structure throughout the process.

R.A. Smith engineers evenly spaced four lifting and rolling points along each pod’s long side. The design featured cold-formed steel (CFS) spreader beams to distribute weight evenly.

Identifying a Pod Rolling Device

Identifying a rolling device capable of supporting the 10,000-pound pods proved critical. The installers applied appropriate safety factors to address the varied loading conditions and transportation methods.

The team initially considered car jacks due to the high load capacity and the ability to easily raise and lower the pods. However, most lacked the 360-degree rotation needed to position the pods. In the end, the team chose caster-type rolling devices. With a suitable rolling device selected, the team discussed lifting the pods. The engineers decided to lift the pods at the location where they would be rolled.

R.A. Smith engineers evenly spaced four lifting and rolling points along each pod’s long side. The design featured cold-formed steel (CFS) spreader beams to distribute weight evenly.

Additionally, the 97 mil posts, spreader beams and clips enabled the highest-capacity connections with the fewest lifting points. Installers removed the spreader beams easily and with minimal disruption to the interior drywall.

Working with LOD 350, R.A. Smith enabled its partners to get a complete picture of the pods’ construction.

R.A. Smith engineered the pods for strength and stiffness to protect interior finishes during movement and maintain their structural integrity.

Design Cuts Carpentry by 40%

17,000 Trade Hours Eliminated

While Section 13/CF2.3 may appear standard, it involved extensive research and problem solving. This project showcases the impact of collaboration and innovation in delivering a solution that significantly reduced costs while preserving structural integrity. The pods’ CFS-framed design cut on-site carpentry by 40%. And that eliminated 17,000 direct trade hours.

The success prompted the hospital to approach R.G. Construction and R.A. Smith to develop a modular prototype for a larger, more complex phase of the project. The Cleveland Clinic has also expressed interest in applying this construction method to future initiatives.

Read the complete story for R.A. Smith’s 2025 CFSEI Design Excellence award here.

Lerner Research Institute

Building CBB – Cleveland ClinicThird Place, Commercial — 2025 CFSEI Design Excellence Award

Winner: R.A. Smith, Inc.Alyssa Pease (center) of SFIA member R.A. Smith accepts the CFSEI Design Excellence Third Place award, Commercial category presented by CFSEI’s Immediate Past Chair Dana Hennis and Chair Tammy Gleed.

Project

Lerner Research Institute

Building CBB – Cleveland Clinic

2134 East 100th Street

Cleveland, Ohio 44106

Completion Date

2025Cost

$2.4 MillionPeople

Owner

Cleveland Clinic Builds and DesignArchitect of Record

Hellmuth, Obata and Kassabaum, P.C. (HOK)Engineer of Record for Structural Work

Hellmuth, Obata and Kassabaum, P.C. (HOK)Cold-Formed Steel Specialty Engineer

Alyssa Pease, R.A. Smith, Inc.Cold-Formed Steel Specialty Contractor

Tom Garcea, Jr., R.G. Construction Services, Inc.

R.A. Smith, Inc.

R.A. Smith has a niche expertise in cold-formed steel (CFS) engineering. The team provides services to architects, builders and general contractors on projects nationwide. R.A. Smith has one of the largest cold-formed steel engineering groups in the United States.

Its CFS structural engineering applications include residential, sports, retail, educational, health care, mixed-use, corporate, industrial, senior living and hospitality facilities.

The firm’s cold-formed designers and technicians are highly responsive and detail-oriented. The speed and quality of project turnaround stem from gathering key information early and preparing complete, easy-to-read drawings before work begins.

For more information, visit rasmith.com

Additional Resources