All images and photos courtesy of Salas O’Brien except where noted.

For the Colorado Convention Center Expansion project in Denver, Salas O’Brien provided the engineering for cold-formed steel (CFS) exterior framing panels, up to 50-feet-tall hanging from the new structure, the exterior envelope CFS framing that ties into an existing blade roof with a new blade roof extension and extensive interior CFS engineering.

The expansion of the Colorado Convention Center includes a new 80,000 square foot column free multipurpose room, an outdoor rooftop terrace with sweeping views of the city skyline and mountains and 150,000 square feet of meeting space.

Select Prefab and Four Star Drywall was the CFS specialty contractor for the project. Martin and Martin Engineering Consultants was the engineer or record for the structural work.

The project received the Design Excellence — Honorable Mention in the 2024 CFSEI Awards presented by the Cold-Formed Steel Engineers Institute. The award entry was submitted by Daniel Stadig, P.E., of Salas O’Brien.

135,000 SF Rooftop Expansion

The expansion of the Colorado Convention Center was a decade in the making, having the goals of better serving modern-day convention-goers, differentiating the facility and ensuring it remains an attractive and global competitor.

Already one of the largest buildings in the city of Denver, the 135,000-square-foot square foot rooftop expansion included the design of what is now the largest ballroom in the state of Colorado. The new Bluebird Ballroom is an 80,000-square-foot column-free multipurpose space that can be subdivided into 19 rooms of varying sizes.

The ballroom connects to a 35,000-square foot, wrap-around, pre-function concourse space with floor-to-ceiling windows and a 20,000-square-foot outdoor rooftop terrace. The terrace provides sweeping views of Denver’s city skyline and the Rocky Mountains.

The Bluebird Ballroom at the Colorado Convention Center, the largest ballroom in Colorado, as seen during construction.

The Bluebird Ballroom is an 80,000-square-foot, column-free space. It can be subdivided into 19 rooms. Photo courtesy of the City and County of Denver

Salas O’Brien provided Division 5400 exterior structural cold-formed steel (CFS) framing engineering and panelized wall fabrication drawings. The firm also provided Division 092216 interior CFS wall and ceiling framing engineering for this project.

The Convention Center expansion superstructure is steel framed with a concrete-over-metal-deck floor diaphragm over the existing roof, which cantilevers over the existing light rail line below the north terrace. The ballroom uses long-span steel trusses with a metal deck roof diaphragm.

Highlights of the project include:

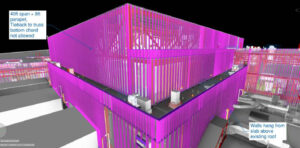

- Exterior framing panels, up to 50-feet-tall, hanging from the new structure above the existing roof

- Exterior envelope framing that ties into an existing blade roof with a new extension

- Extensive interior engineering

Salas O’Brien provided the interior engineering for the ballroom ceiling framing. Here, large sloping ceiling elements match the exterior blade roof. Soffits support 30-foot-span ceiling joists.

Colorado Convention Center’s south-facing prefabricated walls are framed with 40-foot tall, 8” cold-formed steel (CFS) metal studs.

Design Challenges and Solutions

Envelope Wall Panelization

The envelope wall required that the panels meet both the project schedule and downtown Denver site restrictions.

The exterior walls are up to 50 feet tall. They include an 8-foot-tall parapet over a 40-foot long clear span hanging from a new structure above the existing roof. Where walls were able to sit on the existing roof, a blade roof sloping in two directions, the slopes disallowed a traditional bottom track bearing detail.

Additionally, the walls support an insulated metal panel system that spans 30 inches on center. The wall support conditions, panelization, cladding layout and large-size size walls created a complex engineering and coordination challenge.

Salas O’Brien’s cold-formed steel (CFS) framing details show the complex engineering required on the Colorado Convention Center project.

Exterior Panel Engineering

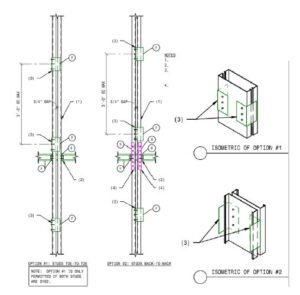

The heaviest wall framing was (2) 1000S200-97 with (2) 1000T200-97 full-height cap tracks at 30 inches on center with double welded TSN DTLB clips at the base; 43mil steel studs were required between the heavy exterior studs for interior drywall attachment.

The IMP layout requirements and opening widths forced a panel layout that required adjacent panels to be connected. Due to the size of the panels, Salas O’Brien created details that connected the metal studs for cladding out-of-plane support, while still allowing for in-plane thermal movement between the steel-framed panels.

Salas O’Brien created cold-formed steel (CFS) stud connection details for cladding out-of-plane support, while allowing for in-plane thermal movement between panels.

The exterior framing shown here hangs above the existing roof over a louver where the track would not fit.

Since this was a DriftTrack® system from SFIA member The Steel Network, Salas O’Brien closely coordinated and confirmed the capacities of the 8-inch clips used with 10-inch deep studs. This was necessary since the system’s largest clip is used typically for no more than an 8-inch steel stud.

At the blade roof, two (2) custom-bent 97 mil angles were used at the wall base to accommodate the slopes.

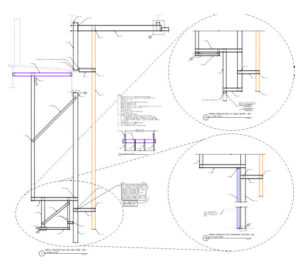

The remaining exterior framing presented its own set of challenges. These included 10-foot-tall crickets, base fascia hanging over the existing roof that is 8-foot tall with built-up brace members and a new blade roof extension with hung-framed ceiling. The latter required welded hangers and other non-typical framing conditions.

Interior Framing Engineering

The convention center spaces feature bold architecture at a large scale. Salas O’Brien designed the ballroom ceiling support with 30-foot span CFS joists that hold baffled ceilings and MEP. The north bay of the ceiling was designed for scaffolding loads to use as a platform to install a roof unit.

The exterior bays in many locations hang from perimeter soffits 40 feet down to the exhibit hall entrance below.

The transition from the pre-function to the ballroom space presented unique challenges: Hanging from the warped blade roof steel on one side to hanging from upper roof steel on the exhibit side, and maintaining deflection compatibility where laterally connected.

Read the complete story and obtain the complete design diagrams for Salas O’Brien’s 2024 CFSEI Design Excellence — Honorable Mention Award here.

This Salas O’Brien detail shows a 10-foot cantilevered blade roof soffit within the pre-function space that imitates the continuation of the iconic exterior blade roof. It’s an example of how large-scale exterior features are reflected in interior spaces at the Colorado Convention Center.

Colorado Convention Center Expansion

Honorable Mention — 2024 CFSEI Design Excellence Award

Winner: Salas O’Brien

Project

Colorado Convention Center Expansion

700 14th Street

Denver, CO 80202Completion Date

December 2023Construction Cost

$233 MillionPeople

Owner

City and County of DenverArchitect of Record

Justin Hughes, Thompson, Ventulett, Staiback & Associates, Inc.Engineer of Record for Structural Work

Kelly Knowles, Martin and Martin Engineering ConsultantsCold-Formed Steel Specialty Engineer

Russ Leffler, Salas O’BrienCold-Formed Steel Specialty Contractor

Steve Bradford, Select Prefab and Four Star Drywall

Additional Resources

- Salas O’Brien Wins 2024 CFSEI Award for the Denver International Airport Concourse Expansion Design

- Salas O’Brien Takes Top CFSEI ‘Non-Building’ Award for Colorado Springs Pedestrian Bridge

- 2025 CFSEI Expo: Plan to Attend in Raleigh, N.C. (May 19-21, 2025)