Cold-formed steel (CFS) framing plays a critical role in protecting buildings in fire-prone regions. As bushfires, grass fires and forest fires become more severe and frequent, engineers need reliable data on how exterior wall systems perform under extreme heat.

New research from Australia helps fill that gap with validated numerical modeling that evaluated how CFS-framed walls respond to bushfire flame zone conditions.

Queensland University of Technology published “Numerical Modeling of External Light Gauge Steel Framed Wall Systems Exposed to Bushfire Flame Zone Conditions.” The researchers used new ways to model the heat transfer within wall cavities and the performance of different cladding materials.

The study found that external light gauge steel, or CFS, framed walls are “key components of the building envelope” and that they “play a critical role in resisting bushfire attacks.”

Closing Data Gaps with New Modeling Approach

Bushfire-prone regions rely on exterior walls that resist extreme temperatures and radiant heat. However, engineers still lack broad experimental data for these assemblies.

“Experimental studies on external [CFS] walls under bushfire conditions are costly and scarce,” says the report.

Older numerical models also struggle with cavity radiation and cladding performance. The QUT team addressed these limitations with a more accurate modeling approach.

Fire Safety: 5 Reasons to Use Steel

1. Steel is Noncombustible

Steel can’t burn, because it contains no elements that can serve as fuel.2. Steel Maintains its Noncombustibility

Steel remains noncombustible throughout the entire lifecycle of a building — during construction, occupation and renovation and repair.3. Steel Framing Reduces Fire Risk to Workers and Occupants

Fire-rated walls and floors help contain flames and preserve the integrity of a structure.4. Steel-Framed Buildings Reduce the Impact on Municipal Fire Services

Fires have strained local fire departments, prompting many municipalities to adopt site-safety regulations for combustible buildings.5. Steel-Framed Buildings Tend to Cost Less to Insure

CFS framing saved $1.32 million in builders risk insurance premiums over the 24-month construction of a four-story, 400-unit hotel — plus $66,000 annually in property insurance premiums compared to wood framing.

Refining Bushfire Models Through Testing

The researchers used a fire dynamics simulator to create several heat-transfer models. They refined mesh sizes and radiation settings through repeated testing.

“Through mesh sensitivity analysis (15 mm, 10 mm, 5 mm meshes) and radiation parameter verification, a 10 mm mesh size was selected to balance calculation accuracy and efficiency,” says the report.

The team then built a small 0.6 m × 0.2 m model to reduce computation time while matching full-scale behavior.

The key innovations developed for this research included:

- Building full-scale and small-scale heat-transfer models

- Performing mesh sensitivity studies

- Verifying radiation behavior in cavity spaces

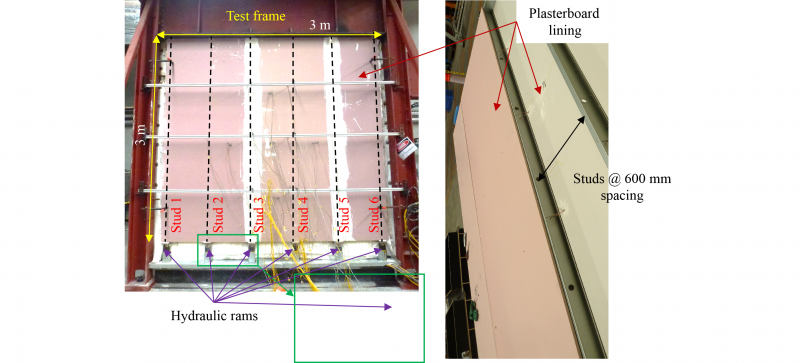

Test set-up and wall test frame showing the team’s 0.6 m × 0.2 m scaled model, designed to reduce computation time while accurately replicating full-scale behavior.

Validating Heat-Transfer Accuracy

The team validated the model using six different CFS wall configurations. These configurations varied by cladding type, plasterboard thickness and stud spacing.

“The model predictions of temperature distribution across the wall thickness (fire side, cavity, ambient side, steel studs) showed good agreement with experimental results, with a maximum model uncertainty of 0.10,” says the report.

Thus, the refined bushfire models reliably simulated heat transfer in complex wall systems. In other words, the tested models accurately predicted temperature between wall layers, validated the performance of different cladding materials and showed strong agreement with full-scale experiments.

Surge in Fires: The Case for Steel Framing

Download this free article brief exploring the rise of fires in mid-rise wood construction across the U.S., highlighting incidents in California and Texas. The report outlines the key advantages of steel framing as a noncombustible alternative to significantly reduce fire hazards.

Key Findings From Bushfire Simulations

The researchers evaluated seven external CFS wall systems under two bushfire curves. Cladding materials significantly influenced thermal behavior. AAC panels provided the strongest thermal protection across tested conditions.

Steel cladding also delayed and reduced fire-side temperatures. Stud temperatures remained below critical thresholds in most configurations.

“Thin-walled steel studs maintained sufficient load-bearing capacity (maximum hot flange temperature 456 °C, less than the critical 550 °C), with yield strength and elastic modulus reduced by less than 20%,” says the report.

Many wall systems remained structurally recoverable after bushfire exposure. Most assemblies required only targeted repairs, such as replacing fire-side cladding.

These findings highlight the resilience of cold-formed steel (CFS) wall systems under extreme thermal loading.

Read the full research summary.

Additional Resources

- CFS10’s Trial by Fire: Photos from UC San Diego’s Burn Tests Prove CFS’s Resilience

- Insurance Costs Are Re-Shaping Construction Choices — And the Data Speaks for Itself

- Data and Noncombustible Materials Hold the Key to Safer Construction, Says SFIA’s Don Allen