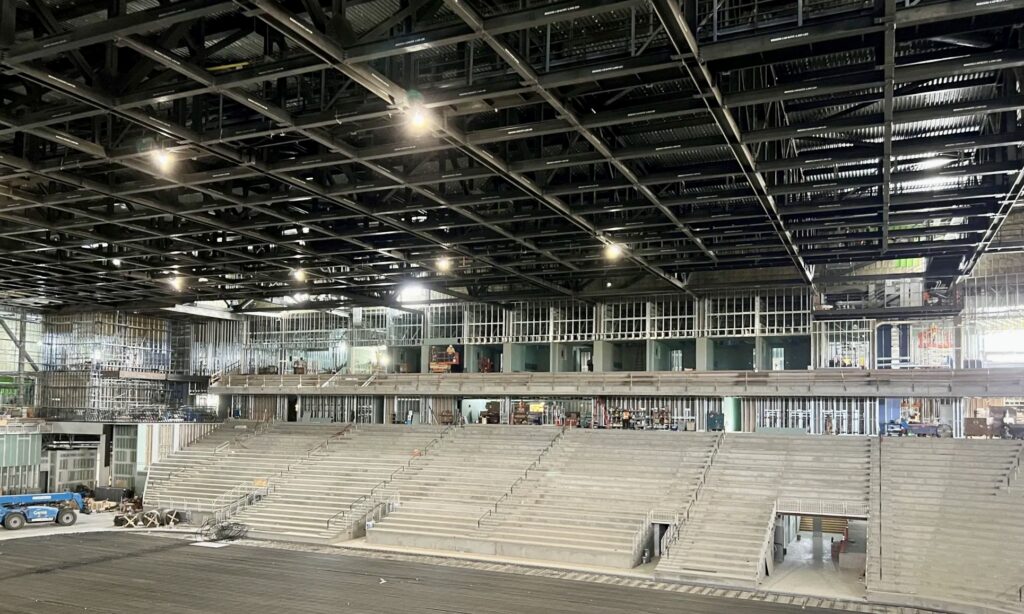

Featured image: Acrisure Arena features 471 tons of cold-formed steel (CFS) framing. Images courtesy of ClarkDietrich.

Acrisure Arena, located in Coachella Valley in California, is 300,000 square feet in size, has seating for more than 11,000 and has hospitality suites and club spaces for premium ticket holders. The arena is home to the Seattle Kraken’s American Hockey League team, the Coachella Valley Firebirds, and includes an adjoining community ice skating facility that serves as a year-round community gathering space.

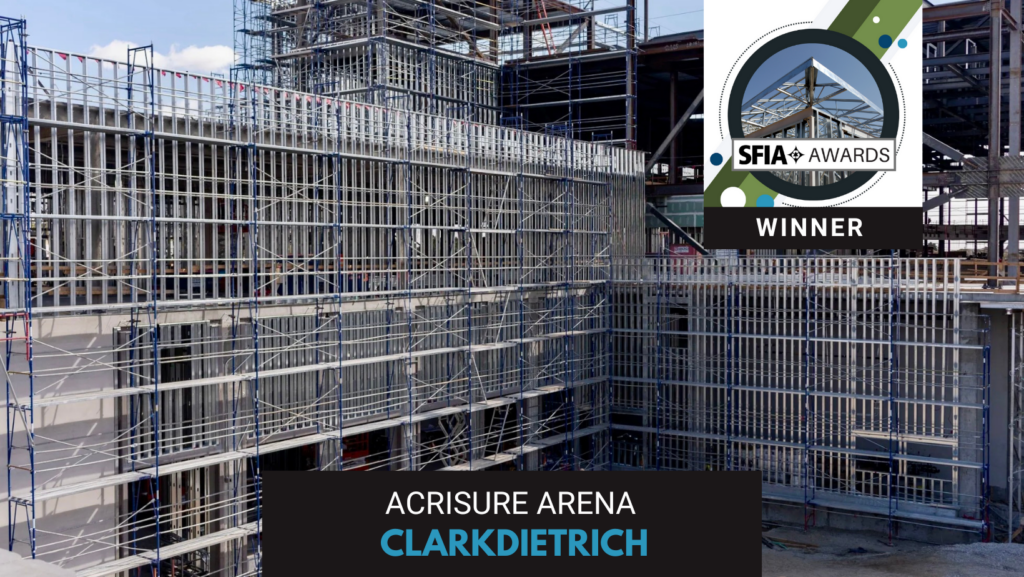

ClarkDietrich, a member of the Steel Framing Industry Association (SFIA), provided 471 tons of cold-formed steel (CFS) for the construction of the arena.

ClarkDietrich, a member of the Steel Framing Industry Association (SFIA), provided 471 tons of cold-formed steel (CFS) for the Acrisure Arena project.

ClarkDietrich is the SFIA 2024 Industry Project Awards winner for Acrisure Arena in the “Sustainable Project” category. The SFIA Awards entry was submitted by Jennifer Edgar, vice president of marketing, ClarkDietrich.

ClarkDietrich’s win was announced at the 2024 SFIA Awards ceremony held live recently and posted online. The SFIA 2024 Industry Project Awards, an annual awards competition, focuses on CFS manufacturing and construction. This year, designers, manufacturers, distributors and contractors entered a variety of projects in the competition.

Design Quality

Did this project make efficient use of metal framing products?

Yes, the Acrisure Arena features CFS framing both in the entire and exterior of the project.

At publication time, the project is pending net-zero carbon certification by the International Living Future Institute. The certification is expected sometime in 2025 according to the Acrisure Arena website. The 2024 SFIA Awards judges noted that the Acrisure Arena architect, Populous, also worked on the Climate Pledge Arena, which was Zero Carbon Certified by the ILFI in 2023.

Acrisure Arena, which features cold-formed steel CFS) framing, is pending net-zero carbon certification by the International Living Future Institute.

Installation Complexity

What difficulties existed on the project?

The project had challenges surrounding the excessive heat in the Coachella Valley. The temperatures during construction at times exceeded 120 degrees, which required keeping two indoor ice rinks cold and added many hours of overtime to maintain the tight construction schedule.

The CFS installer’s scope of work was completed within 7 months, the ClarkDietrich awards submission noted. With 20 executive suites and multiple private premium club spaces, the standards required of construction on the project were exceptionally high.

On the interior portion of the project, the owner hired multiple contractors for tenant improvement, restaurant and concession buildouts. Collaborating effectively with these contractors was crucial to gathering all the necessary information to avoid conflicts and deliver a high-quality project on time.

The dealer installed and integrated Fellert finishes on various wall assemblies with multiple bars, restaurants and jumbotrons.

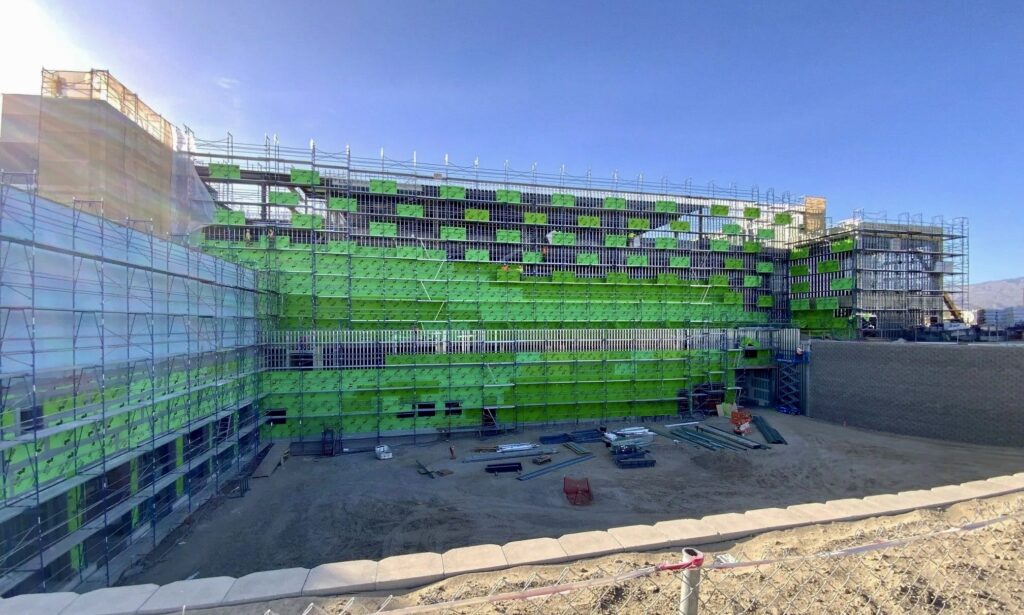

Construction of the exterior was expedited so the arena would be ready for hockey season. This required overtime of many of the crews, who worked in the extreme heat. The main entrance features a large tube steel trellis. Assembling the trellis within the exterior wall systems was a difficult and elaborate task.

Manufacturing Complexity

Were special materials involved?

Regarding the exterior insulation finishing system, the dealer used 2.5” foam to achieve a high R-value — the measurement of an insulating material’s resistance to conductive heat flow. The EIFS also helped to stabilize the arena’s interior temperatures. The EIFS also reduced some of the HVAC requirements in keeping the ice cold. The installer also incorporated a weather and air barrier system behind the EIFS.

ClarkDietrich is the 2024 SFIA Awards winner in the “Sustainable Project” category of cold-formed steel (CFS) for Acrisure Arena.

Acrisure Arena

75702 Varner Rd.

Palm Desert, CA 92211

Details:

300,000 sq.ft., 471 tons of cold-formed steel (CFS) used on the project

PEOPLE

Owner:

Public-Private Partnership between Oak View Group, Seattle Kraken Hockey and Live Nation

Architect:

PopulousGeneral Contractor:

AECOM HuntCold-Formed Steel (CFS)

ClarkDietrich

SFIA Industry Project Awards

The SFIA 2024 Industry Project Awards focus on cold-formed steel (CFS) manufacturing and construction. A panel of industry representatives judged all 2024 SFIA Awards entries based on the following criteria:

- Design Quality, such as the efficient and sustainable use of cold-formed steel (CFS) products

- Installation Complexity, focusing on conflict resolution, timeframe challenges, etc.

- Manufacturing Complexity, including custom orders, panelization, special material sourcing and more

- Overall Job Quality, including the quality of alignments, finishes and other attention to detail

- Conversion from Alternative Framing Material, reflecting how steel framing lowered a structure’s weight, or added stories, or helped lower the project’s builders’ risk insurance, etc.

About SFIA

The Steel Framing Industry Association (SFIA), a unique organization representing steel mills, coil coaters, stud and connector manufacturers, component fabricators, Cold-Formed Steel Engineers Institute (CFSEI) members, suppliers/distributors, contractors and others, provides members with exclusive access to technical cold-formed steel (CFS) framing services, including CFS certification, environmental product declarations, market data and analysis, technical design guides, specification review services, architectural services, the Steel Framing Learning Portal , the SFIA Awards and more. SFIA is an accredited ANSI Standards Development Organization. Follow SFIA on LinkedIn, Facebook, Instagram and X.

Additional Resources

- SFIA Unveils 9 Winners of the 2024 Industry Project Awards

- SFIA Reveals 7 Winners of the 2023 Industry Project Awards in Online Ceremony

- Designers: Update to SFIA’s 2024 Tech Guide for the Latest CFS Load and Span Tables