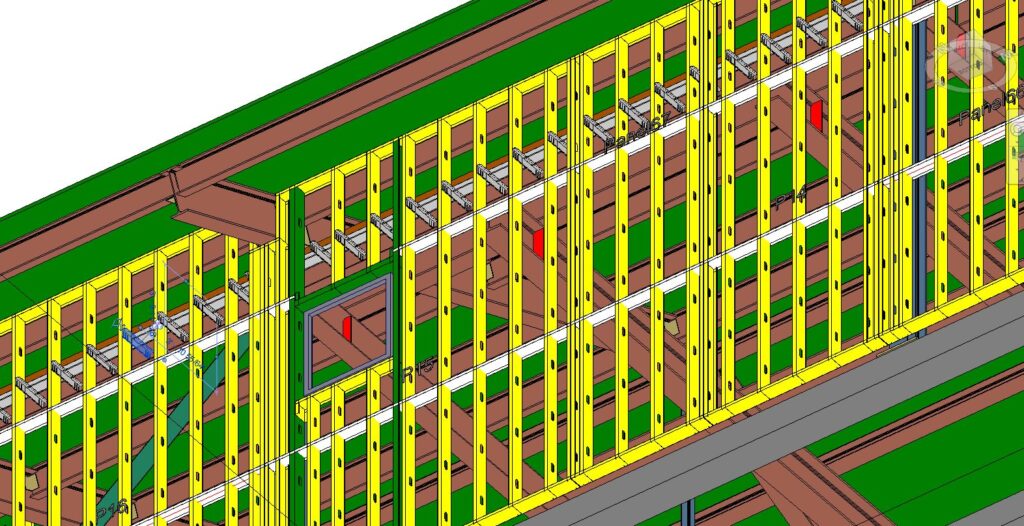

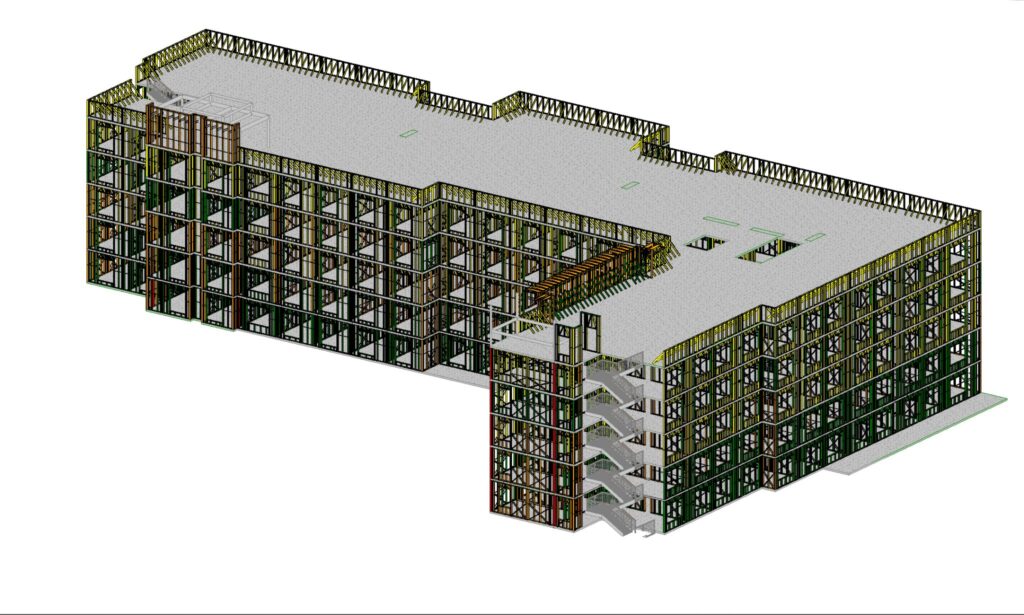

Images courtesy of James Hillegas of BIMTECH Offsite Prefabrication Solutions

The goal of this series of posts, “How to BIM,” is to assist companies in navigating through the waters of adding Building Information Modeling (BIM)-based workflows to their cold-formed steel (CFS) framing projects. The best part about this series is I am making the transition with you, sharing as much as I can without getting fired.

First and foremost, this blog post is going to focus on people. In this article, I am going to assume you have no Virtual Design and Construction (VDC) team. VDC is the term most widely used in construction. VDC includes BIM, but it involves more than just the models and modeling themselves.

If in the past your projects required having such a team, then you either (a) skipped the project and lost out on revenue or (b) hired a third party and lost out on more revenue.

With such an assumption, you need to hire a VDC team — or identify two people within your company to be that team.

Models featuring cold-formed steel (CFS) framed walls provide details that will improve the final product.

VDC Department Head

You will need a Director of VDC, a VDC/BIM Manager or someone with a similar title.

Unless you are looking to completely figure everything out on your own, it’s a good idea to hire someone with prior VDC experience in cold-formed steel (CFS) framing. This person will help establish templates, best practices, document management systems and processes.

Your Director of VDC does not need to have been a CFS framer or installer. But be aware when you hire VDC engineers, a.k.a. detailers, the detailers and your director can bump heads, depending on personality types and backgrounds. Just because your VDC team can draw it one way, does not mean it will get done that way or that it can be built that way.

Hiring Tip:

Look for a VDC Director with a CM-BIM certification. Look for someone who has worked for either an architecture/engineering firm or a subcontractor ahead of you in your VDC journey.

Models are great for the execution of mid-rise construction projects since they help provide certainty in scheduling and in construction profitability.

VDC Department Members

There are 2 important qualities that someone should look for when selecting VDC engineers, draftspersons and modelers. If you find someone with both qualities, lock ’em down.

1. VDC Self-Starters

The first quality is the self-starter — someone who (a) has a passion for construction, a real passion not someone who is here because it’s the latest craze, and (b) someone who can Google.

What I mean is someone who can research and solve their own problems, because often that is what a lot of modeling is, especially when getting started. I am speaking from experience, having submitted 2-3 forum/support emails per day as I struggle to model.

2. VDC Staff with Field Experience

The second quality is someone with field experience. While having been a journeyman is ideal, it’s not required. But the field experience is super useful. I often find myself sitting bent over a drawing table with the shop foreman editing prints to make certain aspects constructible. For example, a stud must be at least 1/2″ shorter than the height of the tracks for field fitting — something I detailed wrong the first time.

There is probably someone within your company that meets some of the requirements. Perhaps it’s someone who has jumped up for BIM/VDC in the past and you shut them down. While there are going to be growing pains and short-term losses, remember you are helping to prevent the larger loss of being less competitive in today’s changing CFS framing and prefabrication landscape.

So, put together your VDC team. And be sure to check back for the second article in this series where I will cover where and how to get the team started.

About BIMTECH Offsite

BIMTECH Offsite Prefabrication Solutions utilizes Framecad, the world’s most advanced, end-to-end, cold-formed steel (CFS), engineer design and build system. This system gives the company the technical tools to accelerate the construction process, increase productivity, accuracy and reduce labor costs through offsite prefabrication of CFS wall panels, trusses and floor joists.

The Steel Framing Advantage

Cold-formed steel (CFS) leads the way as the preferred framing material for prefabricated structures for multiple reasons. CFS is:

- A pre-engineered material that can be cut to exact lengths

- Dimensionally stable and does not expand or contract with changes in moisture content

- Lightweight compared to wood and concrete

- Resilient and will not warp, split, crack or creep when exposed to the elements

- Sustainable and 100% recyclable

- Durable and has a high tensile strength

- Non-combustible and is a safeguard against fire accidents

Find CFS framing suppliers in BuildSteel’s industry wide Product and Provider Directory.

Additional Resources

- Panelized Steel Framing Saves Time and Money for Virginia Hotel Project

- Prefabrication Reaches Mainstream Status with Steel Framing

- 4 Reasons Prefabrication is Here to Stay