The architectural design for Wind Creek Chicago Southland Casino pushed the limits of what can be framed with cold-formed steel.

R.A. Smith’s win was announced during the 2025 SFIA Awards live ceremony and posted online. The SFIA 2025 Industry Project and Product Awards, an annual steel framing industry awards competition, focuses on cold-formed steel manufacturing and construction. Designers, manufacturers, distributors and contractors entered a variety of projects in the latest competition.

Design Quality

Did this project make efficient use of metal framing products?

Wherever feasible, the cold-formed steel design for Wind Creek Chicago Southland Casino incorporated continuous in-plane members such as tracks, strong-backs and kickers spaced at 48” o.c.. The spacing helped to minimize the number of labor-intensive connections. This spacing strategy enhanced efficiency. It allowed for the use of standard CFS sizes and shapes and also for a higher percentage of each connection’s capacity.

In addition, the design called for in-plane gypsum sheathing. The in-plane sheathing formed vertical diaphragms that supported hanging framing. These diaphragms spanned between designated connection points coordinated with in-place MEP systems.

Additionally, the project required creative solutions to ensure that standard, readily available CFS sizes could be used effectively. R.A. Smith team found solutions for in several areas.

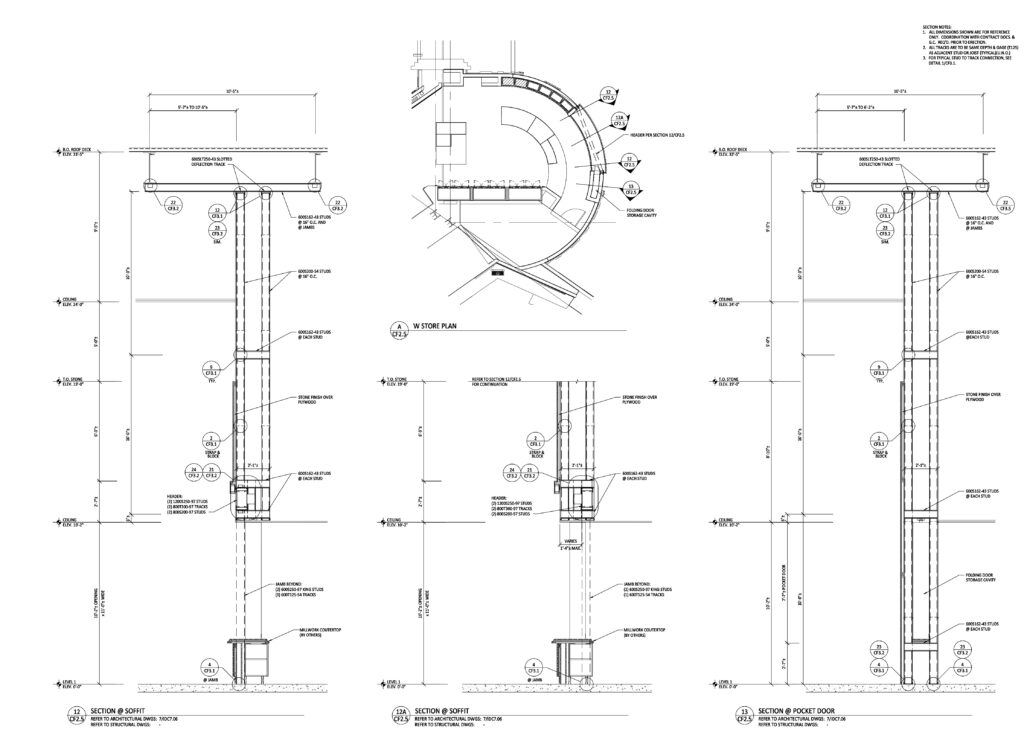

For example, several openings, each nearly 30 feet wide, supported stone panels. Originally, the design plans for these openings called for HSS members. Instead, R.A. Smith’s design team value engineered the approach by using CFS framing members. To span that distance and support the full dead load, the design combined a traditional box header with additional studs framed similarly to an L-header. This configuration provided the required structural capacity using readily available materials.

R.A. Smith value engineered openings by replacing specified HSS members with cold-formed steel (CFS) framing at Wind Creek Chicago Southland Casino.

R.A. Smith designed cold-formed steel (CFS) framing to support attention-grabbing interior finishes.

Installation Complexity

What difficulties existed on the project?

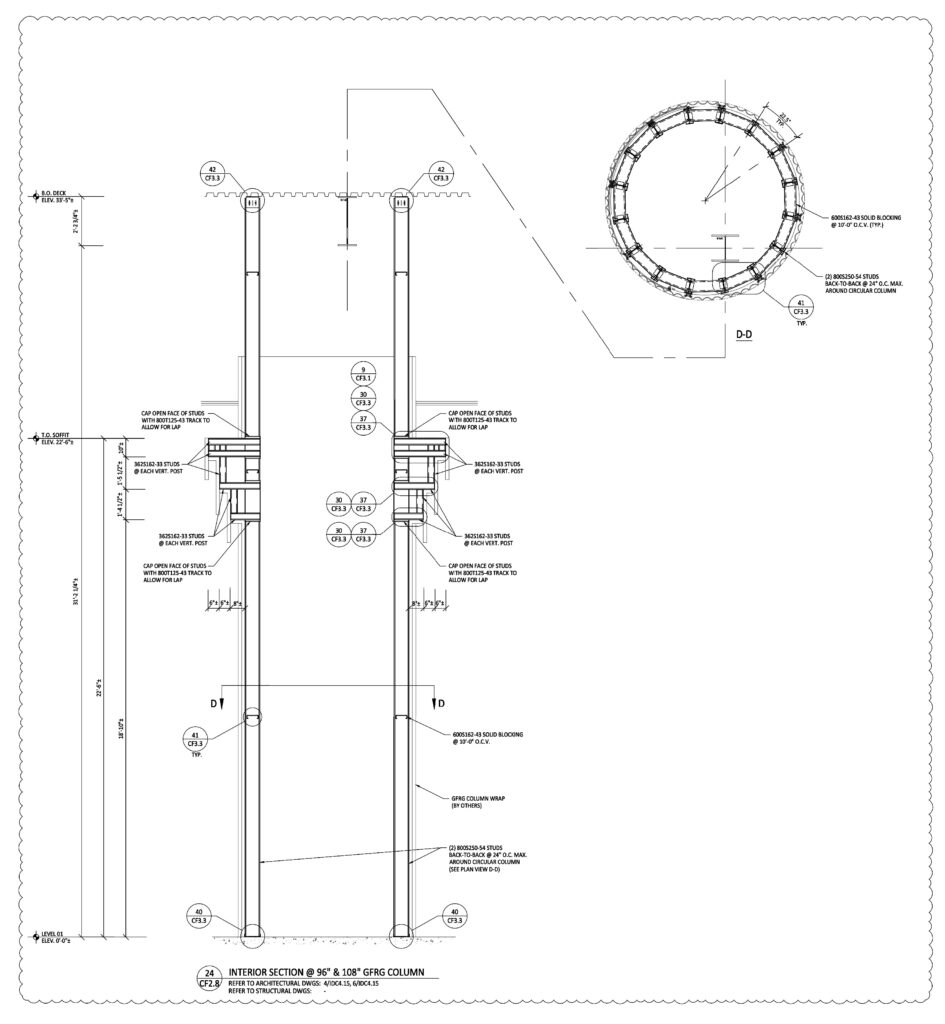

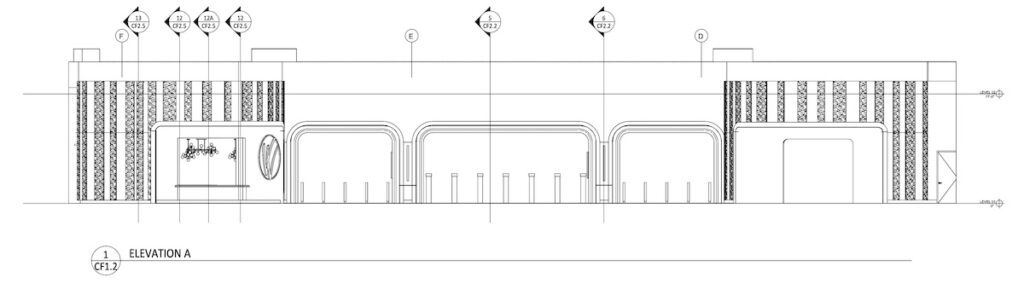

The architectural design for Wind Creek Chicago Southland Casino pushed the limits of what can be framed with cold-formed steel. It required creative engineering solutions. The team designed cold-formed steel framing to support attention-grabbing interior finishes. The CFS framing system handles 30-foot-plus floor-to-floor heights, large openings and soffits, curved and sloped walls and soffits and multi-tiered column covers. Each framing condition presented unique challenges. Together, they significantly increased the complexity of the project.

Typical interior framing projects rely on technical support from the SFIA, or support from manufacturers on the limiting heights for the CFS studs, and often do not require additional engineering. However, Wind Creek Chicago Southland Casino project was different. It needed delegated design engineering support. Essentially, it became a design-build project. Since CFS budgets are often already determined when engineering is requested for interior framing, the R.A. Smith team had to engineer efficient, buildable framing solutions within fixed cost constraints.

The R.A. Smith team developed framing systems using strong-backs, kickers and continuous in-plane members to manage the project’s complexity. This strategy reduced clip counts and minimized labor-intensive connection points.

Cold-formed steel (CFS) frames curved walls at Wind Creek Chicago Southland Casino. See the shop drawing for this assembly below.

Manufacturing Complexity

Were special materials involved?

The project used standard, readily available cold-formed steel framing shapes. Crews assembled the CFS framing on site, rather than panelize the wall interior systems. Suppliers made this possible without any significant issues.

Overall Job Quality

How did the completed system turn out?

The completed CFS interior framing system at Wind Creek Chicago Southland Casino met all expectations across each key aspect of the project. The CFS framing features unique and creative designs. The cold-formed steel provides reliable support for the high-end architectural features. Overall, the CFS system fulfilled the design intent, balancing the project’s structural performance and aesthetic quality.

R.A. Smith is the 2025 SFIA Industry Project and Product Awards winner in the Low Rise category.

East Hazel Crest, Illinois

Details: 70,000 square feet

PEOPLE

Owner

Wind Creek HospitalityArchitect

Nelson Daroff DesignGeneral Contractor

R.G. Construction ServicesCFS Engineer

R.A. Smith

SFIA Industry Project and Product Awards

The 2025 SFIA Industry Project and Product Awards focus on cold-formed steel (CFS) manufacturing and construction. A panel of industry representatives judged all 2025 SFIA Awards entries based on the following criteria:

- Design Quality, such as the efficient and sustainable use of CFS products

- Installation Complexity, focusing on conflict resolution, timeframe challenges, etc.

- Manufacturing Complexity, including custom orders, panelization, special material sourcing and more

- Overall Job Quality, including the quality of alignments, finishes and other attention to detail

- Conversion from Alternative Framing Material, reflecting how steel framing lowered a structure’s weight, or added stories, or helped lower the project’s builders’ risk insurance, etc.

About SFIA

The Steel Framing Industry Association (SFIA), a unique organization representing steel mills, coil coaters, stud and connector manufacturers, component fabricators, Cold-Formed Steel Engineers Institute (CFSEI) members, suppliers/distributors, contractors and others, provides members with exclusive access to technical cold-formed steel (CFS) framing services, including CFS certification, environmental product declarations, market data and analysis, technical design guides, specification review services, architectural services, the Steel Framing Learning Portal , the SFIA Awards and more. SFIA is an accredited ANSI Standards Development Organization. Follow SFIA on LinkedIn, Facebook, Instagram and X.

Additional Resources

- The Steel Framing Industry Association (SFIA) Names 13 Recipients of the 2025 Industry Awards

- SFIA Unveils 9 Winners of the 2024 Industry Project Awards

- SFIA Reveals 7 Winners of the 2023 Industry Project Awards in Online Ceremony