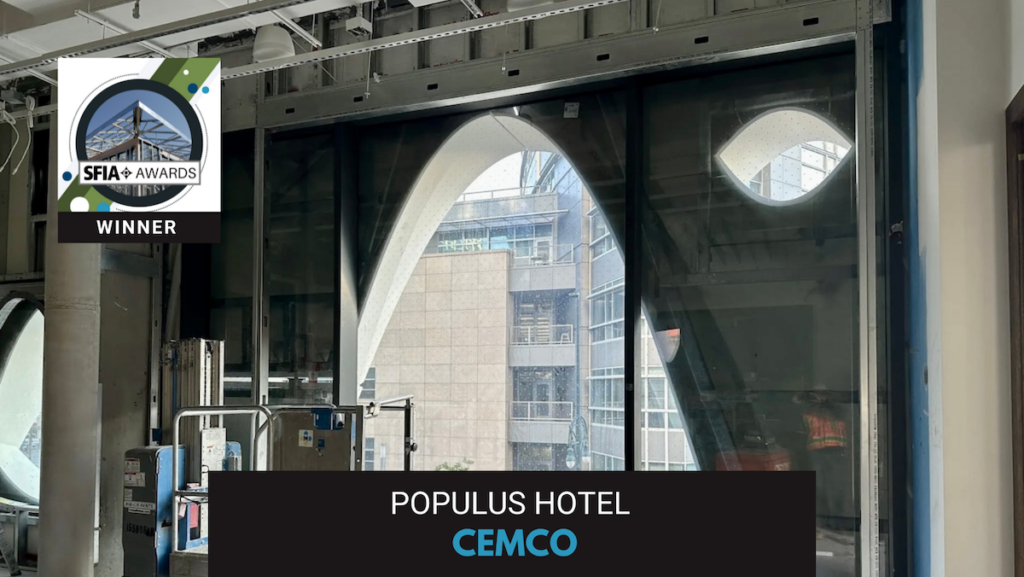

Designed by Jeanne Gang’s Studio Gang team, the Populus hotel brings a Colorado identity to downtown Denver, and it features curvy cold-formed steel (CFS) framing applications everywhere.

Rising 13 stories and housing 265 guest rooms, the building takes its cues from the state’s signature aspen groves. Street-level columns evoke tree trunks. The sculpted window openings echo the dark knots left when aspens shed their branches. Each window is crowned with a subtle overhang — an architectural “eyelid” — that shields interiors from intense mountain sun and reduces energy demand. SFIA member CEMCO supplied the interior cold-formed steel (CFS) studs used to create the framing for these windows and for the interior walls.

CEMCO, which produced 150 tons of CFS framing components for the project, is the 2025 SFIA Industry Project and Product Awards winner for the industrial park project, winning in the Architectural Design Detail category. Carl Peterson of CEMCO submitted the SFIA Awards entry.

Featured image: The Populus hotel in Denver features cold-formed steel (CFS) framing. Images courtesy of CEMCO.

The Populus hotel in Denver features 150 tons of CEMCO cold-formed steel (CFS) framing to form window “eyelids” and more.

CEMCO’s win was announced at the 2025 SFIA Awards ceremony held live recently and posted online. The SFIA 2025 Industry Project and Product Awards, an annual awards competition, focuses on CFS manufacturing and construction. Designers, manufacturers, distributors and contractors entered a variety of projects in the 2025 competition.

Design Quality

Did this project make efficient use of metal framing products?

The Populus hotel features cold-formed steel (CFS) products provided by SFIA member CEMCO throughout the hotel’s interior. The project also featured CFS framing in the hotel’s penthouse.

The interior of Populus has no straight, 90-degree angles. Therefore, the project team value engineered the interior wall systems, choosing an interior CFS framing system to provide strength, save costs and fulfill the architect’s design intent. Thus, the project’s interior featured an efficient use of CFS framing throughout.

The Populus hotel features cold-formed steel (CFS) products provided by SFIA member CEMCO. The interior has no straight, 90-degree angles. Photo courtesy of CEMCO.

Installation Complexity

What difficulties existed on the project?

Everything is radiuses inside this aspen tree inspired, LEED® Gold certified, carbon positive, high-rise hotel.

CEMCO and the interior subcontractor, 4K Painting & Drywall used many unique design and installation methods to complete the architect’s vision. These include radius walls, custom windows and stringent sound mitigation requirements. Every aspect of construction proved challenging for both the CEMCO and 4K Painting & Drywall. However, the subcontractor did have all the equipment needed to complete the job.

Manufacturing Complexity

Were special materials involved?

Because every interior wall curved, the team had to frame the project on site. The custom installations and unique job conditions demanded hands-on field work throughout construction. Early in the process, the project team concluded that cold-formed steel panelization would not make sense for such a highly customized interior.

The Populus project team value engineered the interior cold-formed steel (CFS) framing system to provide strength, save costs and fulfill the architect’s design intent.

The project team used resilient CEMCO cold-formed steel (CFS) efficiently throughout the hotel’s interior.

At Populus, the general contractor found minimal punch list items. The cold-formed steel (CFS) framing achieved the design intent of architect, Studio Gang.

Overall Job Quality

How did the completed system turn out?

The punch list items were minimal. Both the Interior subcontractor and the general contractor were “very pleased with achieving the design intent of this challenging and beautiful project,” the project entry submission says.

CEMCO is the 2025 SFIA Industry Project and Product Awards winner for the Populus hotel in Denver, winning in the Architectural Design Detail category.

Populus Hotel – Interior

Denver, Colorado

Details: 150 tons of cold-formed steel (CFS), 135,000 project square footage, 13 stories, 265 guest rooms

PEOPLE

Owner

Aparium Hotel GroupArchitect

Studio GangGeneral Contractor

The Beck GroupStructural Engineer of Record

Studio NY

CFS Interior Contractor

4K Painting & Drywall

SFIA Industry Project and Product Awards

The 2025 SFIA Industry Project and Product Awards focus on cold-formed steel (CFS) manufacturing and construction. A panel of industry representatives judged all 2025 SFIA Awards entries based on the following criteria:

- Design Quality, such as the efficient and sustainable use of CFS products

- Installation Complexity, focusing on conflict resolution, timeframe challenges, etc.

- Manufacturing Complexity, including custom orders, panelization, special material sourcing and more

- Overall Job Quality, including the quality of alignments, finishes and other attention to detail

- Conversion from Alternative Framing Material, reflecting how steel framing lowered a structure’s weight, or added stories, or helped lower the project’s builders’ risk insurance, etc.

About SFIA

The Steel Framing Industry Association (SFIA), a unique organization representing steel mills, coil coaters, stud and connector manufacturers, component fabricators, Cold-Formed Steel Engineers Institute (CFSEI) members, suppliers/distributors, contractors and others, provides members with exclusive access to technical cold-formed steel (CFS) framing services, including CFS certification, environmental product declarations, market data and analysis, technical design guides, specification review services, architectural services, the Steel Framing Learning Portal , the SFIA Awards and more. SFIA is an accredited ANSI Standards Development Organization. Follow SFIA on LinkedIn, Facebook, Instagram and X.

Additional Resources

- The Steel Framing Industry Association (SFIA) Names 13 Recipients of the 2025 Industry Awards

- SFIA Unveils 9 Winners of the 2024 Industry Project Awards

- SFIA Reveals 7 Winners of the 2023 Industry Project Awards in Online Ceremony