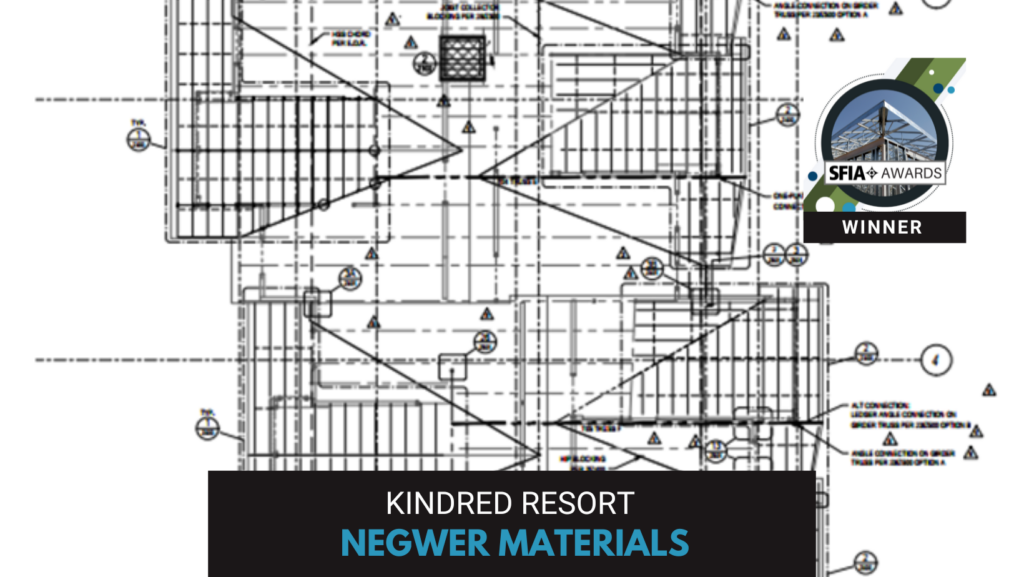

Steel Framing Industry Association (SFIA) member Negwer Materials, Inc. and Engineered Steel Products, a division of Negwer Materials, received the 2025 SFIA Industry Project and Product Award in the Mid Rise category. SFIA members ClarkDietrich and MiTek also participated in the project. Karl Klostermann of Engineered Steel Products submitted the SFIA Awards entry.

Featured image: Kindred Resort / One River Run development features cold-formed steel (CFS) framing. Images courtesy of Engineered Steel Products.

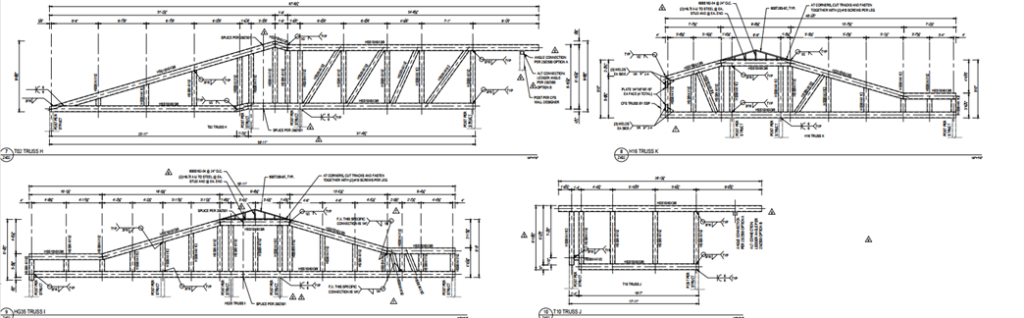

The Kindred Resort joist framing plan shows thick, 12-inch-deep cold-formed steel (CFS) members with flange widths ranging from 1-5/8 inches to 3 inches.

Negwer Materials’ win was announced during the 2025 SFIA Awards live ceremony and posted online. The SFIA 2025 Industry Project and Product Awards, an annual steel framing industry awards competition, focuses on cold-formed steel manufacturing and construction. Designers, manufacturers, distributors and contractors entered a variety of projects in the latest competition.

Design Quality

Did this project make efficient use of metal framing products?

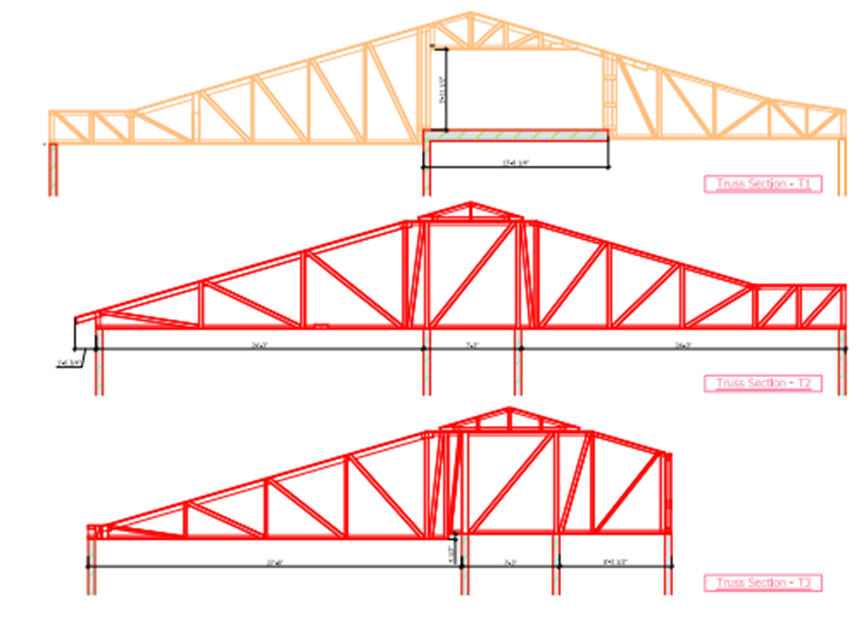

Kindred Resort / One River Run development made efficient use of cold-formed steel products. For example, project designers specified 12-inch cold-formed steel joists to create lightweight vaulted ceilings. Also, MiTek engineered cold-formed trusses to transfer diaphragm loads effectively and minimize the overall dead load on the building. The final designs achieved long, open spans. Cold-formed steel framing’s inherent strength-to-weight ratio helped to achieve these spans without the need for heavier structural systems.

“This approach provided a value engineering solution by reducing material quantities and simplifying installation,” said Klostermann in his awards entry submission. Value engineering lowered “both structural costs and construction time, while preserving the desired architectural aesthetic,” he said.

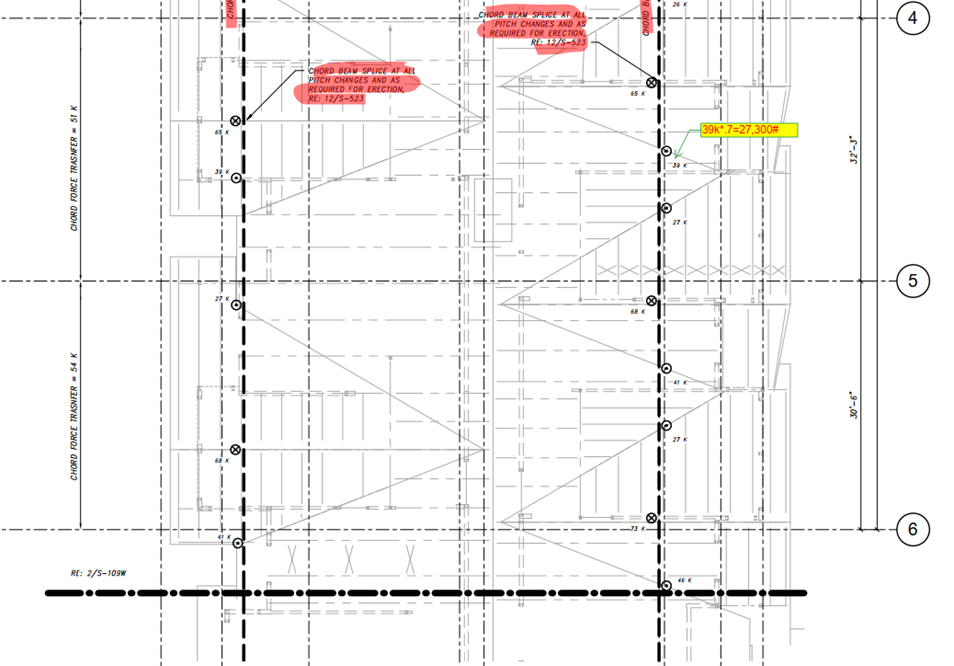

Open floor plan conditions created drag load transfer demands. The engineer used blocking and chord beam load paths to transfer drag loads.

Installation Complexity

What difficulties existed on the project?

This project presented several complex installation challenges requiring special means and methods.

1. Open Floor Plan

The open floor plan limited the number of interior walls available for diaphragm load transfer. To fulfill the design intent, the project team installed drag trusses blocking and complex connections to beams and elevator shafts to properly distribute loads.

2. Vaulted Ceilings

The vaulted ceilings constrained available space for mechanical systems. This required detailed Building Information Modeling coordination to identify and resolve potential conflicts before and during installation.

3. Site Logistics

Construction took place at the base of a mountain within a ski resort. The location introduced difficult site logistics — the result of limited staging space, a steep terrain and the five-story building height.

4. 100-Ft.+ Truss Spans

Many of the truss loads spanned over 100 feet in length. Their installation required careful sequencing and specialized rigging to maneuver and install these large components safely within the tight site constraints. Close collaboration between the trades maintained a safe work site while meeting the project schedule.

To create the varying roof planes at Kindred Resort, the truss designer coordinated closely with the steel fabricator to ensure truss profiles aligned with the complex roof geometry.

The project team designed truss sections to accommodate mechanical equipment within the vaulted top-story roof assemblies.

Chord beam drag loads created high forces at roof plane transitions. The team used HSS trusses in these select locations.

Manufacturing Complexity

Were special materials involved?

This project involved a high degree of manufacturing complexity. The lightweight cold-formed steel trusses were designed to support HSS tube steel beams and ridge beams. The design needed these beams to fulfill the vaulted ceiling architecture. Because the diaphragm loads were significant, the design team fabricated seven trusses from HSS tube steel to meet structural performance requirements.

The project team used panelization as a key strategy, preassembling large framing sections off-site to improve quality control and accelerate field installation. This approach mitigated staging constraints and addressed the difficult terrain at the mountain resort site. The design, fabrication, and installation teams coordinated closely to ensure crews manufactured all custom components accurately and delivered them on schedule.

Conversion to Steel

How was conversion to metal framing achieved?

The project team selected cold-formed steel framing to reduce overall structural weight and accelerate the construction schedule. The system minimized dead load on the podium level, which proved critical for the five-story structure sitting on a challenging mountain terrain. Crews handled and installed the lighter framing in the field. The team also prefabricated CFS components to speed assembly, maintain tight sequencing and keep the project on schedule despite the complex site logistics and variable mountain weather.

Overall Job Quality

How did the completed system turn out?

The completed system achieved a high level of alignment quality.

The team relied on BIM modeling and precise layout to align girder trusses and transfer roof loads accurately — through the cold-formed steel walls — to the podium level. This coordination allowed crews to install structural connections exactly as the design required, reducing field adjustments and preserving the clean architectural lines of the vaulted ceilings and open floor plan.

“The result was a finished structure that met both the performance requirements and the aesthetic goals of the project,” wrote Klostermann in his 2025 SFIA Awards entry submission.

Negwer Materials and Engineered Steel Products is a 2025 SFIA Industry Project and Product Awards winner, winning in the Mid Rise category.

Cold-formed steel (CFS) supplied by Negwer Materials, Inc., and its division and Engineered Steel Products, contributed to lightweight vaulted ceilings at Kindred Resort / One River Run.

Kindred Resort / One River Run

Dillon (Keystone), Colorado

Details: 136.08 tons of cold-formed steel (CFS), 400,000 square feet, 5-story mid rise

PEOPLE

Owner

Vail Summit Resorts, Inc.Architect

OZ Architecture, Inc.General Contractor

PCL ConstructionEngineer

KL&AInstalling Contractor

Midwest PartitionsParticipating SFIA Members

Negwer Materials and Engineered Steel Products, ClarkDietrich, MiTek

SFIA Industry Project and Product Awards

The 2025 SFIA Industry Project and Product Awards focus on cold-formed steel (CFS) manufacturing and construction. A panel of industry representatives judged all 2025 SFIA Awards entries based on the following criteria:

- Design Quality, such as the efficient and sustainable use of CFS products

- Installation Complexity, focusing on conflict resolution, timeframe challenges, etc.

- Manufacturing Complexity, including custom orders, panelization, special material sourcing and more

- Overall Job Quality, including the quality of alignments, finishes and other attention to detail

- Conversion from Alternative Framing Material, reflecting how steel framing lowered a structure’s weight, or added stories, or helped lower the project’s builders’ risk insurance, etc.

About SFIA

The Steel Framing Industry Association (SFIA), a unique organization representing steel mills, coil coaters, stud and connector manufacturers, component fabricators, Cold-Formed Steel Engineers Institute (CFSEI) members, suppliers/distributors, contractors and others, provides members with exclusive access to technical cold-formed steel (CFS) framing services, including CFS certification, environmental product declarations, market data and analysis, technical design guides, specification review services, architectural services, the Steel Framing Learning Portal , the SFIA Awards and more. SFIA is an accredited ANSI Standards Development Organization. Follow SFIA on LinkedIn, Facebook, Instagram and X.

Additional Resources

- The Steel Framing Industry Association (SFIA) Names 13 Recipients of the 2025 Industry Awards

- SFIA Unveils 9 Winners of the 2024 Industry Project Awards

- SFIA Reveals 7 Winners of the 2023 Industry Project Awards in Online Ceremony