For decades, construction teams have followed a familiar sequence – architects design, engineers refine and builders solve challenges on site. This approach delivers projects, but it struggles to meet today’s demands for speed, cost certainty and sustainability.

To address these challenges, developers increasingly adopt Design for Manufacture and Assembly strategies. In the article “Why Developers Are Moving from Traditional Design to DfMA,” Steel Framing Industry Association (SFIA) member FRAMECAD explains why developers are rethinking how buildings move from design to delivery.

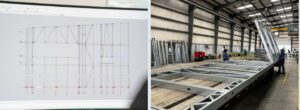

Cold-formed steel (CFS) framing aligns naturally with DfMA by enabling precise manufacturing, rapid assembly and consistent performance.

Images provided by FRAMECAD.

What Is DfMA?

Design for Manufacturing and Assembly (DfMA) designs buildings for efficient factory production and rapid on-site assembly. DfMA shifts complexity off the jobsite by resolving design and fabrication decisions early.

Cold-formed steel framing supports DfMA through precision manufacturing, lightweight components and consistent performance.

Shifting Complexity Off the Jobsite

Traditional construction depends heavily on site conditions, labor availability and sequential coordination. FRAMECAD identifies these factors as recurring sources of delays, waste and cost overruns. Weather exposure, material variability and late coordination often force adjustments during construction.

DfMA addresses these risks by resolving manufacturing and assembly decisions early in design. Teams shift problem-solving upstream, where controlled conditions support consistency and accuracy. Factory-based processes replace jobsite improvisation with repeatable, predictable workflows.

This transition reduces rework and improves overall delivery reliability.

Cold-formed steel framing supports DfMA through precision manufacturing, lightweight components and consistent performance.

Numbers Behind the Movement

DfMA adoption continues to accelerate across domestic and global construction markets. The U.S. construction market using DfMA reached $39.55 billion in 2021 and is projected to reach $90.33 billion by 2031.

Developers respond to this growth because DfMA addresses labor shortages, reduces waste, improves quality control and accelerates delivery.

5 Reasons Developers Are Moving to DfMA

- Predictable Outcomes – DfMA resolves design and coordination issues before construction, reducing redesign and rework

- Faster Speed to Market – Factory-produced components can reduce project schedules by 20-60%

- Improved Cost Control – Automation and reduced on-site labor support 20-40% cost savings

- Consistent Quality – Controlled manufacturing delivers repeatable precision and reliable quality assurance

- Sustainability and Safety Benefits – Offsite production reduces waste, improves safety and lowers site disruption

CFS Enables Design-to-Build

Cold-formed steel framing (CFS) plays a central role in effective DfMA execution. Steel framing provides dimensional stability, lightweight components and full recyclability.

Digital design tools define every profile, opening and connection before fabrication begins. Automated roll forming converts design data directly into manufactured components. This integration supports true design-to-build delivery.

Steel framing supports DfMA by providing:

- Digitally defined components before fabrication

- Automated, repeatable manufacturing accuracy

- Rapid on-site assembly with minimal tools

- High material utilization with minimal waste

Developers benefit from tighter tolerances, faster schedules and buildings that perform as designed.

A Shift in Mindset

DfMA represents more than a process change. It shifts how teams think about design, manufacturing and construction.

Teams treat buildings as products they can standardize, refine and replicate. This approach reduces inefficiency while preserving architectural flexibility. Design teams focus more on performance and occupant experience.

Developers who adopt DfMA early position themselves for long-term success.

Read the full article from FRAMECAD.

About FRAMECAD

FRAMECAD is an advanced, end-to-end design and build system enabling the rapid construction of quality buildings for businesses, governments and communities worldwide.

FRAMECAD offers all the design expertise, intelligent software, steel framing manufacturing solutions, building products and support needed to produce rapid, durable, cost-effective quality buildings.

For more information, visit framecad.com

Additional Resources

- FRAMECAD Offers Strategies for Optimizing Bracing and Anchoring in Steel Framing Projects

- 5 Reasons Developers Specify Steel for Mid-Rise Projects, According to FRAMECAD

- FRAMECAD Posts Beginners Guide to Steel Frame Manufacturing