On November 19, 2025, in a live awards ceremony held online, Don Allen, executive director of the Steel Framing Industry Association (SFIA), announced the 9 winners and 4 honorable mentions of the 2025 SFIA Industry Project and Product Awards. The SFIA Awards recognize excellence in the use of SFIA-certified cold-formed steel (CFS) products, which have passed mechanical, coatings and dimensions tests. SFIA-certified steel represents the top tier in steel framing excellence.

“Each year, the bar rises,” Allen said prior to the awards ceremony.“These projects prove what’s possible with SFIA-certified steel — precision, performance and innovation working together.

2025 SFIA Awards — Winners

- Low-Rise Project: raSmith for the Wind Creek Chicago Southland Casino, East Hazel Crest, Illinois

- Mid-Rise Project: Negwer Materials and Engineered Steel Products, a division of Negwer Materials, for Kindred Resort / One River Run, Dillon (Keystone), Colorado

- High-Rise Project: T.J. McCartney, for Allston Labworks, Boston, Massachusetts

- Efficient Use of CFS Framing: Industrialized Construction Solutions, for West Point II Apartments, Tucson, Arizona

- Conversion from Another Material: CEMCO for Mullin Transportation Design Center, Pasadena, California

- Architectural Design Detail: CEMCO for the Populus hotel interior, Denver, Colorado

- Sustainable Project: Industrialized Construction Solutions, for Sunset & Decatur Industrial Park Phase 1, Las Vegas, Nevada

- Judges Choice: KHS&S Contractors for Dark Universe at Epic Universe in Universal Orlando Resort, Orlando, Florida

- Innovative Product: StepStuds™ from Horizontal Base Studs, LLC

2025 SFIA Awards — Honorable Mentions

- Low-Rise Project: CEMCO for UCSC Student Housing, Santa Cruz, California

- Mid-Rise Project: raSmith for The Trade Hotel, Milwaukee, Wisconsin

- High-Rise Project: ClarkDietrich for 24th & Rio Grande Housing, Austin, Texas

- Architectural Design Detail: Maxan Interior Systems for Westerly 2 — South Tower Canopy, Etobicoke, Ontario

2025 Winners

1. raSmith

Wind Creek Chicago Southland Casino, East Hazel Crest, Illinois

Low-Rise Project: The architectural design for this project pushed the limits of what is possible to be framed with cold-formed steel (CFS), requiring creative engineering solutions. The interior finishes needed attention-grabbing features throughout. With that in mind, SFIA member raSmith designed CFS framing to support 30’+ floor-to-floor heights, large openings, radiused and sloping walls and soffits and multi-tiered column covers.

A GRFG column wrap covers cold-formed steel (CFS) framing at Wind Creek Chicago Southland Casino. Photo courtesy of raSmith.

Check back. More about this project to come.

2. Negwer Materials / Engineered Steel Products

Kindred Resort / One River Run, Dillon (Keystone), Colorado

Mid-Rise Project: This project made efficient use of cold-formed steel (CFS), using 12″ joists to achieve the vaulted ceiling designs while maintaining a lightweight structure. SFIA members Negwer Materials, Inc. and its division Engineered Steel Products, along with SFIA members MiTek and ClarkDietrich provided prefrabricated CFS systems and CFS trusses engineered to transfer diaphragm loads effectively and minimize the overall dead load on the building. The design achieved long, open spans without the need for heavier structural systems.

Cold-formed steel (CFS) supplied by Negwer Materials, Inc., provided lightweight vaulted ceilings at Kindred Resort / One River Run. Photo courtesy of Negwer Materials.

Check back. More about this project to come.

3. T.J. McCartney

Allston Labworks, Boston, Massachusetts

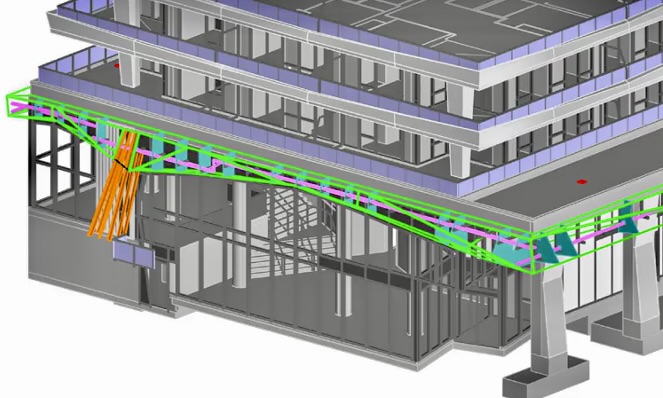

High-Rise Project: SFIA member T.J. McCartney, Inc., made extensive use of BIM and laser layout systems during preconstruction to fulfill the design intent of Allston Labworks. The project made efficient use of cold-formed steel (CFS) products to eliminate the need for heavy and more costly HSS support for the curtainwall. Numerous fly-by box jambs, prefabricated on site, spanned a few stories.

Numerous fly-by box jambs, prefabricated on site, span a few stories at Allston Labworks. T.J. McCarney installed them with a tower crane. Photo courtesy of T.J. McCarney.

Learn more about this project.

4. Industrialized Construction Solutions

West Point II Apartments, Tucson, Arizona

Efficient Use of CFS Framing: SFIA member Industrialized Construction Solutions, Inc., helped leverage cold-formed steel (CFS) to build a 7-story superstructure without a concrete podium. The project features vertically aligned bearing walls that eliminated concrete and red iron transfers. Built-up CFS stud packs were used in lieu of HSS for shear wall hold-downs and balcony support. Project savings: More than $1 million.

Industrialized Construction Solutions used cold-formed steel (CFS) to build a 7-story structure without a concrete podium. Vertically aligned bearing walls removed the need for concrete and red-iron transfers. Photo courtesy of ICS.

Check back. More about this project to come.

5. CEMCO

Mullin Transportation Design Center, Pasadena, California

Conversion from Another Material: The Mullin Transportation Design Center features cold-formed steel (CFS) products provided by SFIA member CEMCO. CFS maximized the strength-to-weight ratio, reducing the structural load on the original slab while allowing for architectural flexibility. CFS was selected in lieu of heavier structural framing for non-load bearing partitions, soffits and ceiling structures, which reduced material costs.

The Mullin Transportation Design Center features cold-formed steel (CFS) provided by SFIA member CEMCO, products that supported the project’s LEED certification goals. Photo courtesy of CEMCO.

Check back. More about this project to come.

6. CEMCO

The Populus Hotel Interior, Denver, Colorado

Architectural Design Detail: Populus hotel features cold-formed steel (CFS) products provided by SFIA member CEMCO. Cold-formed steel was used throughout the hotel’s interior, including the rooftop penthouse area. The interior has no straight, 90-degree angles. The project team value engineered the interior wall systems with CFS to provide strength, save costs and fulfill the architect’s design intent.

The Populus Hotel features cold-formed steel (CFS) products provided by SFIA member CEMCO. The interior has no straight, 90-degree angles. Photo courtesy of CEMCO.

Learn more about this project.

7. Industrialized Construction Solutions

Sunset & Decatur Industrial Park Phase 1, Las Vegas, Nevada

Sustainable Project: This industrial warehouse complex was conceived as an energy-efficient alternative to tilt-up concrete construction. SFIA member Industrialized Construction Solutions, Inc., produced load-bearing, prefabricated cold-formed steel (CFS) panels, some as tall as 35 feet. The panels allowed for a continuous insulated envelope using exterior rigid and cavity batt insulation — delivering superior energy efficiency.

Industrialized Construction Solutions, Inc., produced load-bearing, prefabricated cold-formed steel (CFS) panels for the exterior of six warehouses at the Sunset & Decatur Industrial Park in Las Vegas. Photo courtesy of ICS.

Learn more about this project.

8. KHS&S Contractors

Dark Universe at Epic Universe in Universal Orlando Resort, Orlando, Florida

Judges Choice: KHS&S Contractors completed a unique theme park that encompasses 6 connected structures. Collectively, they create a movie-like overlap of roof lines, “sinking” walls and chimneys and unique angles. SFIA members KHS&S Contractors, ClarkDietrich and Foundation Building Materials made efficient use of cold-formed steel (CFS) connectors, bridging/blocking, headers, jambs and other support applications. CFS played a key role in supporting many long-span ceilings and MEP systems.

SFIA member KHS&S Contractors used cold-formed steel (CFS) connectors, headers, jambs and more at the Dark Universe at Epic Universe theme park. Image provided by KHS&S.

Learn more about this project.

9. StepStuds™

Horizontal Base Studs, LLC

Innovative Product: StepStuds™ from SFIA member Horizontal Base Studs, LLC, lifts gypsum board off the floor to keep it dry during most water intrusions and floods. StepStuds are simple to install — 36 seconds per 8′ piece — at floor level around the perimeter of a room. The product requires just one screw per vertical stud. StepStuds, U.S. Patent #11,702,850, has created a new category of metal studs that has never existed before.

StepStuds™ were invented by a carpenter who, while making a flood repair, realized he could dramatically reduce flood repair costs.

Learn more about this product.

2025 Honorable Mentions

1. CEMCO

UCSC Student Housing, Santa Cruz, California

Low-Rise Project: Crews used a mix of cold-formed steel (CFS) and light-gauge framing from SFIA member CEMCO to frame 30 residential buildings and two community centers in just three months. With 130 workers and four cranes, the metal framing contractor beat the schedule despite frequent Santa Cruz rain. The team panelized the project, framing all walls off site, trucking them in and craning them into place.

CEMCO cold-formed steel (CFS) catches the evening light at a UCSC housing project, where crews framed 30 buildings and two community centers in three months. Photo courtesy of CEMCO.

Check back. More about this project to come.

2. raSmith

The Trade Hotel, Milwaukee, Wisconsin

Mid-Rise Project: This project made efficient use of cold-formed steel (CFS). SFIA members raSmith and ClarkDietrich tailored the framing design to accommodate varying floor-to-floor heights, including extra-tall levels for professional athletes. Each level was engineered to optimize material use and structural performance. Where possible, structural steel was avoided in favor of CFS. The design team communicated efficiencies through approver notes.

Cold-formed steel (CFS) framing played a starring role in The Trade Milwaukee, where raSmith tackled custom window systems, stacked atrium spans and more. Photo courtesy of raSmith.

Check back. More about this project to come.

3. ClarkDietrich

24th & Rio Grande Housing, Austin, Texas

High-Rise Project: This housing project features cold-formed steel (CFS) products provided by SFIA members ClarkDietrich, The Steel Network and L&W Supply. It features prefabricated panels and a drift track attachment method. Crews stacked the panels efficiently to create a robust and seamless outer skin for the building. Prefabrication reduced time and costs, while minimizing on-site labor and material waste.

This Austin housing project used prefabricated, cold-formed steel (CFS) panels, designed to ensure secure attachment to the building. Photo courtesy of ClarkDietrich.

Check back. More about this project to come.

4. Maxan Interior Systems

Westerly 2 — South Tower Canopy, Etobicoke, Ontario

Architectural Design Detail: This project employed standard cold-formed steel (CFS) studs to create dynamic, free-flowing architectural shapes. SFIA members Maxan Interior Systems, DASS Metal and MTE Consultants made meticulous calculations to ensure the structure transferred loads back to the foundational concrete and the underlying steel stud “rib” framework. The design fulfilled all aesthetic aspirations.

Using cold-formed steel (CFS) studs, Maxan Interior Systems, DASS Metal and MTE Consultants created sweeping canopy shapes. Image provided by Maxan.

Check back. More about this project to come.

SFIA Awards Judging Criteria

A panel of industry representatives judged all 2025 SFIA Industry Project and Product Awards entries based on the following criteria:

- Design Quality, such as the efficient and sustainable use of cold-formed steel (CFS) products

- Installation Complexity, including conflict resolution, timeframe challenges, etc.

- Manufacturing Complexity, including custom orders, panelization, special material sourcing and more

- Overall Job Quality, including the quality of alignments, finishes and other attention to detail

- Conversion from Alternative Framing Material, reflecting how steel framing lowered a structure’s weight, or added stories, or helped lower the project’s builders’ risk insurance, etc.

The 2025 SFIA Awards focus on CFS manufacturing, construction and product innovation. The awards program is a complement to the Design Excellence and Creative Detail awards presented by the Cold-Formed Steel Engineers Institute (CFSEI), SFIA’s sister organization.

About SFIA

The Steel Framing Industry Association (SFIA), a unique organization representing steel mills, coil coaters, stud and connector manufacturers, component fabricators, Cold-Formed Steel Engineers Institute (CFSEI) members, suppliers/distributors, contractors and others, provides members with exclusive access to technical cold-formed steel (CFS) framing services, including CFS certification, environmental product declarations, market data and analysis, technical design guides, specification review services, architectural services, the Steel Framing Learning Portal , the SFIA Awards and more. SFIA is an accredited ANSI Standards Development Organization. Follow SFIA on LinkedIn, Facebook, Instagram and X.

Additional Resources

- SFIA Unveils 9 Winners of the 2024 Industry Project Awards

- 2023 SFIA Awards: 7 Key Learnings about Using Cold-Formed Steel (CFS)

- SFIA Releases Revised Industry Environmental Product (EPD) Declaration for Cold-Formed Steel Framing

- SFIA’s Steel Framing Learning Portal Has Metal Framing Education (24/7/365)