Featured image: Fairfax Market, a mid-rise development in Cleveland, features cold-formed steel (CFS) framing. Images courtesy of ADTEK Engineers.

Fairfax Market is a mixed-use grocery market and Medley apartment complex built to help transform Cleveland’s Fairfax neighborhood. The project was a partnership between the City of Cleveland, Cleveland Clinic, Meijer, Fairfax Renaissance Development Corporation and Fairmount Properties. It has provided a new shopping destination for customers from surrounding neighborhoods and created at least 50 new jobs.

ADTEK Engineers, Inc., a member of the Steel Framing Industry Association (SFIA), designed the cold-formed steel (CFS) framing systems for Fairfax Market.

ADTEK Engineers, a member of the Steel Framing Industry Association (SFIA), provided the cold-formed steel (CFS) engineering designs for Fairfax Market.

ADTEK Engineers is the SFIA 2024 Industry Project Awards winner for the Fairfax Market mixed-use project in Cleveland, winning in the Mid-Rise category. The SFIA Awards entry was submitted by Andrew Newland of ADTEK Engineers.

ADTEK Engineers’ win was announced at the 2024 SFIA Awards ceremony held live recently and posted online. The SFIA 2024 Industry Project Awards, an annual awards competition, focuses on CFS manufacturing and construction. This year, designers, manufacturers, distributors and contractors entered a variety of projects in the competition.

Design Quality

Did this project make efficient use of metal framing products?

This project is a 6-story building. It consists of 1 floor of non-load bearing framing with post-tensioned concrete slabs and 5 stories of panelized CFS wall framing.

Typical floor and roof framing were constructed with 16-inch deep CFS trusses consisting of standard shapes built with in-house roll-forming machines. Using trusses allowed for the CFS to achieve greater than typical spans with a lighter material. Corridors were supported with standard 10-inch deep studs.

The lateral force resisting system was a combination of concrete and masonry shear walls at elevator and stair wells, as well as numerous X-braced CFS walls. CFS was also used to build stair framing.

CFS comprised all components of the stairs from risers, steps, stringers and landings. Steel framing was also used to support heavy loading from window washing anchors at the roof level.

The 2024 SFIA Awards judges noted that the awards submission had “excellent construction photos” and “distinct narratives for each aspect of the project.”

The project was also a conversion from wood to CFS.

The project made an “unusual use of open web steel joists” for the floors, the judges said. “For this type, you can use one machine to fabricate instead of the usual two machines needed for punched out joists,” they added.

Installation Complexity

What difficulties existed on the project?

There were numerous issues which needed to be resolved during this project. Wall panels were a maximum of 12-feet long and tall due to shipping constraints. This caused issued at the 6th floor to roof transition and limited the length of shear walls. At the roof transition, parapet framing had to be rigidly attached to top of wall panel to achieve the parapet heights. This was done using straps and proprietary clips.

Additionally at the roof, CFS roof joist framing was used to support window washing equipment anchors. These anchors required special detailing of the joist and wall members to support the heavy loads and moments induced by the loading requirements.

A skewed cold-formed steel (CFS) bearing wall with CFS trusses is supported by ledger and angle at Fairfax Market.

An interior cold-formed steel (CFS) bearing wall shows the stiffeners that were added to the continuous trusses.

Manufacturing Complexity

Were special materials involved?

The majority CFS wall framing was panelized. The walls were a maximum of 12-feet long due to shipping constraints. The typical wall studs were rolled at the panel shop using 6-inches deep framing with 2-inch flanges that ranged from 54 to 97 mils.

The truss members were also rolled at the panel shop using 3-5/8 inch deep by 1-3/4 inch flange material ranging from 33 to 54 mils. Truss members were connected to the wall framing using a custom ledger.

Overall Job Quality

How did the completed system turn out?

The final project turned out well. However, during construction, there were several alignment issues needed to be overcome.

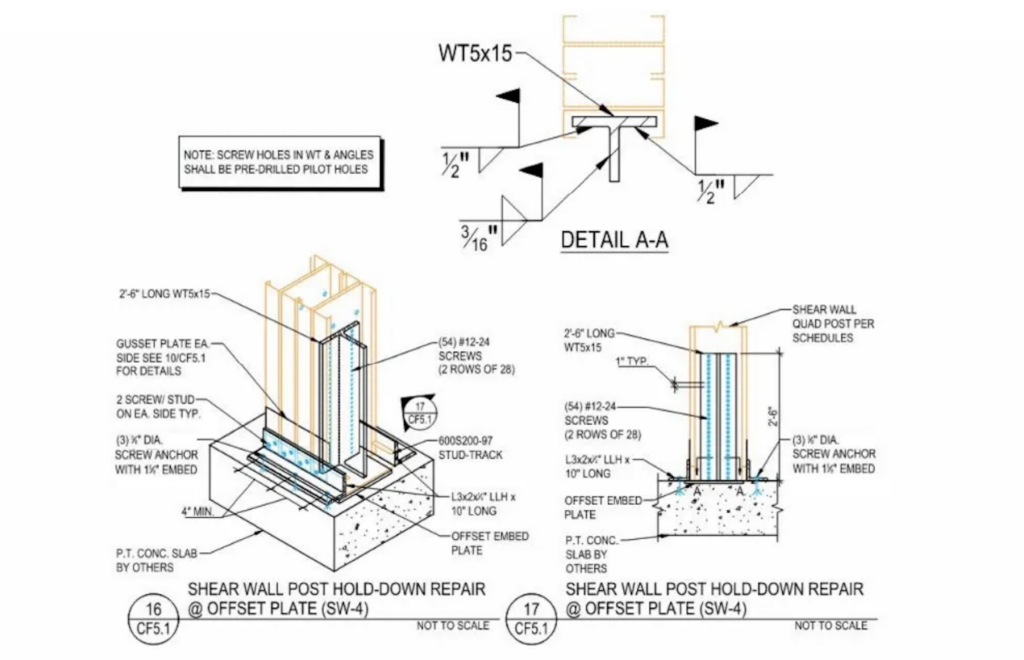

During the design phase, base plate sizes were indicated to the general contractor to be included as embed plates into the post-tension slab. There were numerous alignment issues and/or improperly sized plates provided which required further anchorage into the post-tension slab to transfer loads from the X-braced shear walls into the post-tension slab. This required further design and detailing to ensure these loads were properly transferred.

At portions along the 2nd floor, the outer edge of the slab did not align with the outer edge of 2nd floor exterior load bearing wall framing. To achieve full bearing beneath the exterior wall framing, multiple options were designed and detailed for varying magnitudes of overhang distance.

An Interior cold-formed steel (CFS) bearing wall, a winning design, features openings and continuous trusses at Fairfax Market.

Conversion to Steel

How was conversion to metal framing achieved?

Originally, this project was specified as wood framed. ADTEK Engineers worked up front with the panelizer to convert the wood framing to panelized CFS stud walls and CFS trusses. The use of panelized CFS framing and CFS trusses boosted the speed of construction and eliminated the use of the combustible wood materials.

ADTEK Engineers is the 2024 SFIA Awards winner in the High Rise category of CFS for the Alloy project. The project also involved SFIA members Howick, for its stud rolling, and Simpson Strong-Tie, for its shear wall hold-downs.

2190 E 105th St.

Cleveland, OH 44106Details:

155,000 square feet mid-rise structure

PEOPLE

Owner

Fairmont PropertiesArchitect

Bialosky / Ray CorbyEngineering Firm

Thorson Baker + Associates / Kyle RichardsGeneral Contractor

JGJ / Grant SchwedeOther Providers

Tober Building Company

Howick

Simpson Strong-Tie

SFIA Industry Project Awards

The SFIA 2024 Industry Project Awards focus on cold-formed steel (CFS) manufacturing and construction. A panel of industry representatives judged all 2024 SFIA Awards entries based on the following criteria:

- Design Quality, such as the efficient and sustainable use of CFS products

- Installation Complexity, focusing on conflict resolution, timeframe challenges, etc.

- Manufacturing Complexity, including custom orders, panelization, special material sourcing and more

- Overall Job Quality, including the quality of alignments, finishes and other attention to detail

- Conversion from Alternative Framing Material, reflecting how steel framing lowered a structure’s weight, or added stories, or helped lower the project’s builders’ risk insurance, etc.

About SFIA

The Steel Framing Industry Association (SFIA), a unique organization representing steel mills, coil coaters, stud and connector manufacturers, component fabricators, Cold-Formed Steel Engineers Institute (CFSEI) members, suppliers/distributors, contractors and others, provides members with exclusive access to technical cold-formed steel (CFS) framing services, including CFS certification, environmental product declarations, market data and analysis, technical design guides, specification review services, architectural services, the Steel Framing Learning Portal , the SFIA Awards and more. SFIA is an accredited ANSI Standards Development Organization. Follow SFIA on LinkedIn, Facebook, Instagram and X.

Additional Resources

- SFIA Unveils 9 Winners of the 2024 Industry Project Awards

- SFIA Reveals 7 Winners of the 2023 Industry Project Awards in Online Ceremony

- Designers: Update to SFIA’s 2024 Tech Guide for the Latest CFS Load and Span Tables