ClarkDietrich BlazeFrame® Tape Seals Metal Framing

SFIA member ClarkDietrich, manufacturer of cold-formed steel (CFS) framing products, is offering framing contractors greater flexibility in leveraging the firestopping power of its BlazeFrame family of products with the introduction of BlazeFrame® Tape.

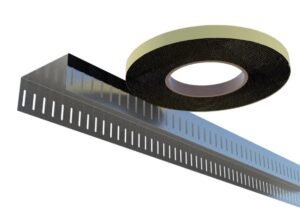

BlazeFrame Tape can be field applied to metal framing profiles to provide an air and smoke seal. Photo Credit: ClarkDietrich

Sold in rolls, BlazeFrame Tape is a 2mm-thick strip of intumescent material that can be field applied to metal framing profiles to provide an air and smoke seal. When exposed to heat above 375º F, the intumescent material expands up to 35 times its size. This provides protection from heat and flame passage during a fire event.

“Field applying BlazeFrame Tape gives contractors the ability to install a fire-rated joint before drywall is installed,” said Ryan Reed, category manager at ClarkDietrich.

Simpson Strong-Tie Introduces Cold-Formed Steel Connector

Simpson Strong-Tie, a supplier of structural building products and an SFIA member, introduced the SUBE bridging connector for cold-formed steel (CFS). The wall-stud bridging connector is designed to connect cold-rolled channels at the end of a wall or single-stud jamb condition, or at the ends of panel walls, curtain walls or load-bearing conditions. The result is faster and simplified bracing with less buildup.

SUBE connects to the open face of the cold-formed steel (CFS) stud limiting drywall buildup to save time and money. Photo Credit: Simpson Strong-Tie

SUBE connects to the open face of the stud, installing with two screws to the stud lips, effectively limiting drywall buildup to save time and money. The u-channel attaches to the bottom of the connector with two additional screws.

Because the connector’s outer flanges allow it to fit snugly over the open side of the stud, no special tools or clamping is required. The design also eliminates sharp-point screw perforations, helping to create a safer work environment.

“By removing the potential for drywall bulge and onsite safety issues, contractors using the SUBE bridging connector can efficiently terminate end-of-wall bracing, saving both time and money,” said Clifton Melcher, group product manager at Simpson Strong-Tie.

Steel-Framed Glass Curtain Walls Meet Architect’s Demands

Architects and designers are increasingly seeking more from glass curtain wall assemblies. They want systems that not only dissolve boundaries between interior and exterior spaces but also maximize natural light penetration, enhance overall building performance and foster visual connectivity.

“Steel-framed assemblies can balance these demands in a single solution,” says Chuck Knickerbocker, manager for Technical Glass Products.

Steel-framed glass curtain walls high strength-to-weight ratio allows for thinner profiles, resulting in narrower sightlines and maximized glazed areas.

Steel curtain walls offer significant advantages by combining aesthetic appeal and structural strength. In comparison with aluminum, new-generation steel-framed glass curtain walls support more weight and greater spans with smaller profiles. Their high strength-to-weight ratio allows for thinner profiles, resulting in narrower sightlines and maximized glazed areas.

Technological advancements in steel framing have further improved these benefits, enabling taller and more efficient curtain wall designs.

Additional Resources

- Simpson Strong-Tie Self-Drilling Screw Fastens CFS to Sheathing, Drywall and Subfloors

- ClarkDietrich Launches SustainabilityPRO, Publishes Corporate Sustainability Report

- Myth Versus Reality: Revealing the Curtain Wall Capabilities of Modern Steel